Comprehensive Analysis of Flexible PCB Materials: Classification and Selection Guide

Hello everyone, this article introduces us to the Flexible PCB materials in depth. In order to help everyone master it quickly, I will introduce only the most commonly used materials. Our need for the materials in the production of flexible circuit boards is divided into main materials and auxiliary materials. Let’s define it simply: the materials that affect the performance of flexible circuit boards are called main materials, such as substrates, Coverlay Films, and EMI Shielding Film; the materials that have no effect on the performance, but only affect its structure on the user’s equipment, and the additional materials that need to be added are called auxiliary materials, such as reinforcement plates and double-sided adhesives. After reading this article, I believe everyone will have a clear understanding of the materials used in flexible circuit boards.

Main of Flexible PCB Materials

As described above, the main materials that affect the performance of flexible circuit boards mainly include substrates, cover films, and electromagnetic films.

Flexible PCB Materials: Substrate

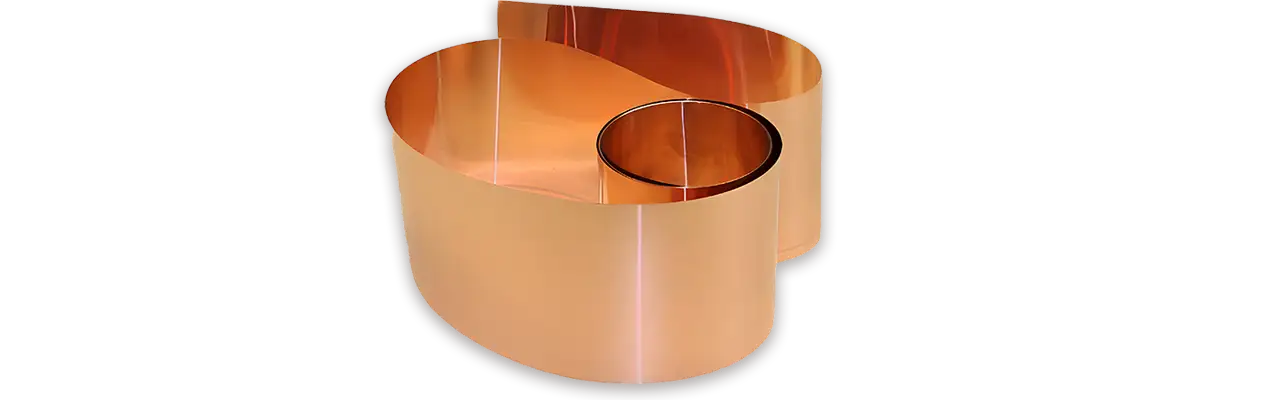

Flexible circuit boards are a type of circuit board, which naturally includes the most basic conductive material: copper foil. We attach the Copper foil to an insulating material (polyimide PI) through a process to form a sheet, we say the sheet is the substrate for flexible PCB. The substrate we purchase comes in the form of a whole roll. The following is our classification of the substrate.

Copper Foil Manufacturing Process

- Rolled Annealed Copper Foil (RA Copper Foil): We generally use RA Copper in dynamic applications that require high flexibility and high reliability (dynamic applications involve repeated bending). We put the copper material into the machine for multiple rolling and annealing processes to make it a thin layer of copper foil. This process results in a uniform, flat internal grain structure. The rolling and annealing process ensures a smooth surface and good flexibility.

- Electrolytic copper foil (ED copper foil): It’s perfect for cost-sensitive, low-flexibility, static applications. We choose electrolytic copper foil in these scenarios. It’s made through an electrolytic deposition process, where copper ions are deposited onto a rotating cathode roller, forming a copper foil layer. This process creates a columnar grain structure with small, loosely arranged grains. Consequently, the surface is relatively rough and its bending performance is poor.

Manufacturing Process of Substrate

- Adhesive Substrate: Initially, the copper foil and polyimide film are separate. We use adhesive to bond them together, forming a thin plate. This plate, called ‘Adhesive Substrate,’ is produced simply and cheaply but lacks flexibility. It’s best for static environments.

- Adhesiveless Substrate: This type skips adhesives. Instead, the copper foil and polyimide film bond under high temperature and pressure. This creates a strong physical and chemical bond, offering better thermal stability and flexibility.

Copper Foil and Polyimide Film Thickness

- Copper Foil Thickness: Copper foil comes in various thicknesses, like 1/3 oz, 1/2 oz, 1 oz, 2 oz, and 3 oz. Thinner copper offers less conductivity but more flexibility, while thicker copper provides better conductivity but less flexibility.

- Polyimide Film Thickness: Available in thicknesses such as 12.5 µm, 25 µm, 50 µm, 75 µm, and 100 µm. Thicker films have higher mechanical strength and better insulation performance but worse flexibility. Thinner films have lower mechanical strength and worse insulation performance but better flexibility.

Classification by Structure

- Single-Sided Flex Substrate: A layer of copper foil on one side of the insulating substrate. This simple structure and process offer good flexibility and are suitable for single-sided circuits and dynamic scenes with repeated folding. It can be combined into single-sided and multi-layer configurations as needed.

- Double-Sided Flex Substrate: Copper foil on both sides of the insulating substrate. This structure is more complex and less flexible. We can through vias(PTH) connect the circuits on both sides. Suitable for static scenes, We can combine into various multi-layer configurations as needed.

Summary: Common consumer electronic products mainly use 1/3 oz and 1/2 oz electrolytic copper, and 12.5 µm and 25 µm PI. We select the appropriate material according to specific needs. If cost is not a concern, Using RA Copper is better for bending and flexibility. Thicker copper and PI layers result in higher conduction current but worse bending performance, suitable for medium and large machines and equipment. What kind of flexible PCB materials we should choose depends on the specific usage conditions.

Coverlay Films

The Coverlay films are also made of polyimide, different from the polyimide film in the substrate. The overlay films attach to the circuit board’s outer layer, providing insulation and wear resistance.

Coverlay Film

Classification by Color

- Transparent Yellow (Amber): Most commonly used.

- White and Transparent: Used on LED light strips.

- Black: Used in scenarios requiring light interference prevention.

Classification by Thickness

- Available in thicknesses such as 12.5 µm, 25 µm, 50 µm, 75 µm, and 100 µm. Thicker films have better insulation, strength, and durability but worse flexibility. Choose the appropriate thickness based on actual usage.

Summary: Coverlay films are essential for flexible circuit boards, providing insulation and protection, with good flexibility and high temperature resistance (up to 300 degrees).

EMI Shielding Film

Flexible circuit boards are susceptible to external electromagnetic interference (EMI). Use the EMI Shielding Film to shield the board from such interference, typically made of various metal foils, with the surface often being black.

Commonly used metal EMI Shielding Films include copper, aluminum, and silver. The selection depends on their shielding capabilities within the frequency range. Well, it can be seen that EMI Shielding Film is also indispensable for flexible PCB materials.

Auxiliary of Flexible PCB Materials

Use the auxiliary materials to bond to the circuit board for reinforcement, pasting, and assembly. They do not affect function or performance, only the assembly structure.

Reinforcement Plate

Flexible materials need support in some scenarios requiring sufficient strength. We put the reinforcement plates to the back for the circuit, to meet structural assembly requirements.

- Steel Sheet: Commonly used, etched into shape and attached to the back of the circuit board for strength. Thickness ranges from 0.1mm to 0.4mm, with 0.5mm rarely used.

- FR4 Reinforcement Plate: A glass fiber-reinforced epoxy resin laminate, with a thickness from 0.15mm to 2.0mm. Non-conductive, suitable where steel sheet is inappropriate or insufficient.

- PI Reinforcement Plate: Often used on the back of pull-out fingers of flexible circuit boards to enhance strength.

Double-Sided Tape

We must use double-sided tape to fix the circuit board to the product shell.

Common Brands and Models: 3M 300LSE, 200LSE, 9448A, 467MP, TESA 8853, and TESA 8854.

How to Choose Double-Sided Tape: Understand performance parameters before choosing. For example, 3M 300LSE has very good viscosity and a thickness of about 0.16mm; 3M 200 has slightly lower viscosity and a thickness of about 0.12mm; 467MP has average viscosity and is the thinnest at 0.05mm; TESA materials can withstand high temperatures and are suitable for wave soldering. Consider viscosity, thickness, and other conditions to select the appropriate double-sided tape.

Summary

When selecting flexible PCB materials, consider whether you need good bendability and flexibility or high conductivity. By identifying the needs in these two aspects and considering the actual cost performance, you can quickly find suitable materials. This approach can meet requirements and avoid unnecessary cost waste.

Links:

Leave A Comment