Exploring the Role of Flexible Printed Circuits in Modern Sensor Technology

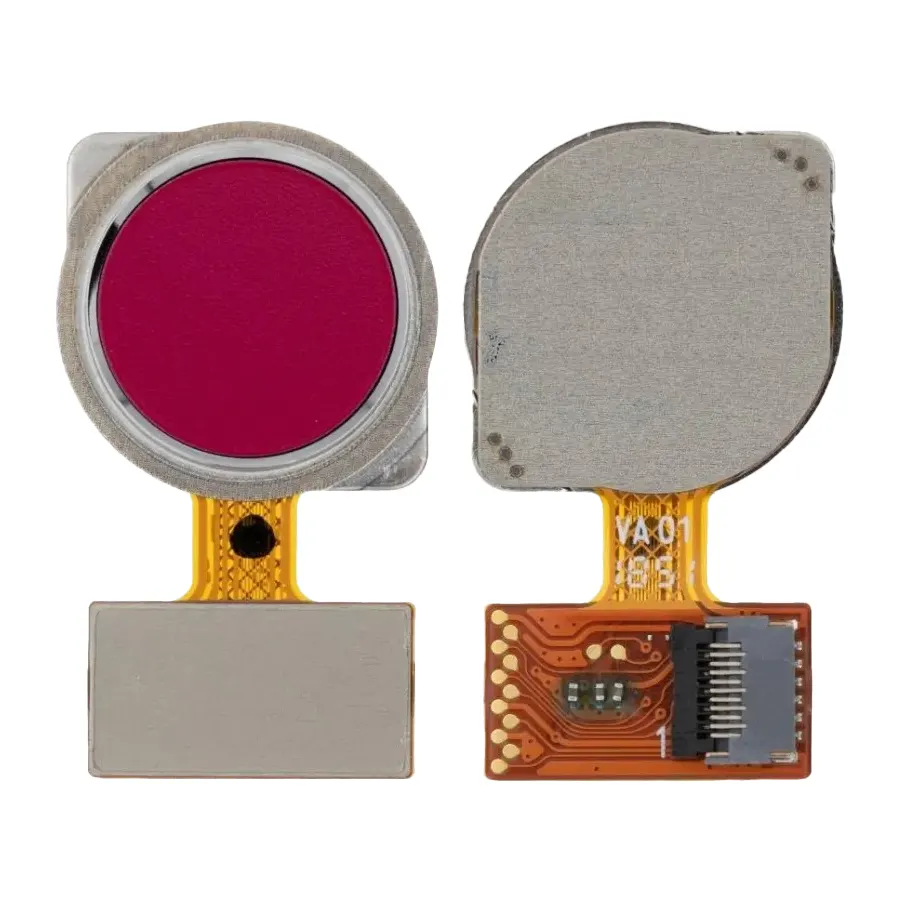

Fingerprint Sensor FPC

How Flexible Printed Circuits are Changing Sensor Technology In the modern world of electronics, Flexible Printed Circuits (FPCs) are vital for innovations around many technologies; sensor solutions are no exception. I will demonstrate how ultra-thin, flexible circuits connect sensors to controls, maximizing space while providing reliable solutions across various markets.

What Makes Sensor FPCs Essential?

Sensor FPCs excel by combining flexibility, robustness, and signal transmission. In contrast, screen-printed circuits are thick and rigid, making them unsuitable for toys and compact devices requiring curves. Meanwhile, sensor FPCs easily conform to the shape of any device, whether in a curved medical instrument or a compact wearable sensor.

Manufacturing Challenges:

Fingerprint sensors and temperature sensors, for example, connect the FPC to the sensor via Ball Grid Array (BGA) pads, which require high levels of precision during assembly. The dense configuration of these pads makes it difficult to maintain proper alignment, especially when the FPC’s covering film is not properly aligned, resulting in misalignment or pad coverage issues.

Moreover, soldering in such high-density connections requires careful management of materials like green solder masks and adhesive films. There are generally two methods used to address these issues:

Green Solder Mask Printing:

This involves applying a layer of green ink to cover the circuit traces and pads. This helps prevent unwanted connections and ensures correct isolation, In order to avoid misalignment with the solder pads, it must be carefully aligned.

Film Lamination

Adding an additional layer of protection to the FPC involves laminating a thin film over it. High-density designs often use this method, but the film must be precisely applied to avoid covering pads and causing electrical connection failures.

Key Features of Sensor FPCs

- Space-Efficient Design

However, one of the most significant benefits that sensor fps offers is its ability to save space inside devices that are required to incorporate multiple sensors at once. Their ultra-thin form factor – often less than 0.1mm – minimizes the footprint of the electronics inside the device; ideal for smartphones, wearables, and automotive systems where size matters. - High Flexibility and Durability

Sensor FPCs are designed to permit bending and twisting over and over again, an important quality to have for wearable health monitors or robotics systems that require continuous motion. They also withstand extreme environments well, like temperature changes, moisture, and vibrations, to provide consistent functionality over time. - Stable Signal Transmission

For sensors that rely on accurate data transfer, such as temperature sensors or fingerprint sensors, sensor FPCs ensure stable and high-quality signal transmission. Their advanced construction minimizes signal loss, providing precise readings and enhancing the overall performance of the device.

Applications of Sensor FPCs

Camera Sensor FPC

The use of sensor FPCs is widespread, especially in fields that require reliability, accuracy, and space efficiency. Here are some common uses:

- Fingerprint Recognition: Sensor FPCs for fingerprint sensors enable secure and fast biometric authentication in smartphones, tablets, and security devices. Their flexibility ensures that they fit seamlessly within compact and curved spaces.

- Temperature Sensing: Featuring real-time, accurate monitoring, temperature sensor FPCs enable thermometers, wearables, and industrial machines to operate properly under extreme conditions.

- Camera Sensors: Camera FPCs are essential for modern imaging devices. High-quality photography and video recording in everything from smartphones to professional cameras relies on these thin flexible circuits, which wash over the image sensor to the mainboard. They are quite lightweight and take up little space so It is possible to integrate cameras into even the smallest devices.

The Future of Sensor FPC Technology

The future holds even more promise with the need for sensor FPCs growing in tandem with the call for smarter, smaller, and more robust technologies across various industries. As sensor FPC usage becomes more widespread in the fields of wearable electronics, automotive safety systems, and IoT devices, it will become an integral part of innovation across different industries. As such circuits become increasingly customizable and economical, manufacturers should expect more design efficiency and improved product functionality.

Why Choose Sensor FPCs?

- Reliability: Ensures stable performance in critical applications like medical devices and industrial sensors.

- Flexibility: Perfect for applications with limited space, curved surfaces, or moving components.

- Efficiency: Reduce the weight of devices and their sizes, and make their functions better.

- Sustainability: Eco-friendly and compliant with regulations such as RoHS and REACH.

Conclusion

Sensor FPCs are transforming how devices integrate and manage sensor systems. From biometric sensors to temperature monitors and even high-definition cameras, Such flexible circuits help build a different set of elements that suits the needs of contemporary technology due to their flexibility, durability, and efficiency. Sensor FPCs will continue to play a key role in the electronics industry as demand for smaller, smarter, and more efficient devices proliferates.

Learn about others

What is the Sensor? https://en.wikipedia.org/wiki/Sensor

What is the Image sensor?: https://en.wikipedia.org/wiki/Image_sensor

Leave A Comment