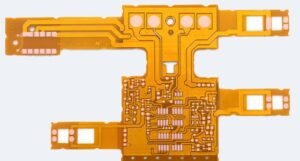

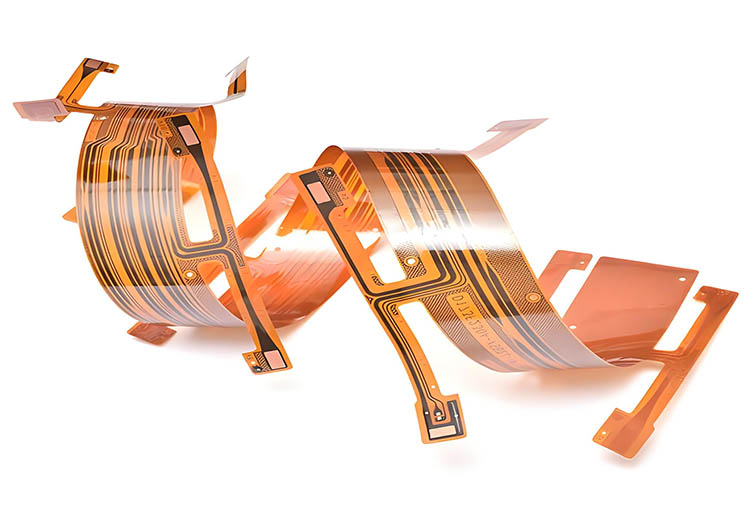

Surface Mount Technology (SMT) for flex PCB assembly

introduction

Surface Mount Technology (SMT) is a method where surface-mounted components (SMC/SMD) with no leads or short leads are mounted on the surface of printed circuit boards (PCB) or other substrates.SMT is a surface assembly technology, which is the most popular technology and process in the flex PCB assembly industry. This is achieved through reflow soldering or wave soldering techniques.

Electronic products typically consist of PCBs combined with various capacitors, resistors, and other electronic components designed according to circuit diagrams. Consequently, a variety of SMT processing methods are necessary to accommodate the diverse range of electronic devices.

Common SMT Processing Solutions

Solution 1: Multi-Piece Mounting

In this method, a positioning template positions multiple FPCs (Flexible Printed Circuits) on a carrier plate, and then they undergo SMT mounting together.

1. Application Scope:

– Component Types: Generally, chip components larger than 0603, QFPs with a lead pitch of 0.65mm or more, and other components.

– Component Quantity: Several to dozens of components per FPC.

– Mounting Precision: Medium precision requirements.

– FPC Characteristics: Larger area with unoccupied regions, at least two optical positioning MARKs, and more than two positioning holes.

2. FPC Fixation:

FPCs are fixed on a high-precision positioning template using CAD data. The positioning template aligns with positioning holes on the FPCs. Before SMT, high-temperature-resistant tape fixes FPCs on the carrier plates to prevent movement, which are made to match these templates. After printing and mounting, the tape should be easily removable without leaving residue.

Solution 2: High-Precision Mounting

We fix a single or multiple FPCs onto a high-precision positioning carrier plate for SMT mounting.

1. Application Scope:

– Component Types: Almost all standard components, including QFPs with lead pitches less than 0.65mm.

– Component Quantity: Dozens of components or more.

– Mounting Precision: High precision, suitable for QFPs with a lead pitch of 0.5mm.

– FPC Characteristics: Larger area with several positioning holes, optical positioning MARKs, and critical component optical positioning markers.

2. FPC Fixation:

We fix FPCs on high-precision custom carrier plates. These plates have high accuracy and minimal deformation after repeated high-temperature exposure. The plates feature two types of positioning pins to ensure alignment and limit FPC movement during the printing and mounting process.

High-Precision SMT Mounting Requirements and Considerations

1. FPC Fixation Direction:

– Determine the optimal fixation direction for the FPC before creating the stencil and carrier plate to minimize the likelihood of soldering defects during reflow soldering.

2. Moisture Sensitivity:

– Like encapsulated SMD components, FPCs are moisture-sensitive. You should store them in a moisture-free environment and dry them before mounting them.

3. Solder Paste Handling:

– Solder paste should be stored in a sealed, low-temperature environment. Before use, you must bring it to room temperature and stir it to ensure proper consistency.

4. Environmental Conditions:

– The temperature should be around 20°C, and humidity should be below 60% for optimal solder paste printing.

5. Stencil Characteristics:

– The stencil thickness should be between 0.1mm and 0.5mm, and the apertures should be 10% smaller than the pad size. High precision prefers laser-cut stencils.

6. Solder Paste Characteristics:

– Choose solder paste with spherical particles, a diameter of about 40µm, and a solder content of 90-92%.

7. Printing Parameters:

– Use polyurethane blades with a hardness of 80-90 degrees and an angle of 60-75 degrees. Printing speed should be 10-25mm/s, with pressure adjusted to achieve clean solder paste transfer.

8. Reflow Soldering:

– Use forced hot air convection reflow soldering to ensure uniform temperature distribution. You should carefully set the reflow profile to accommodate the specific solder paste and component characteristics.

Conclusion

The quality of SMT on FPCs depends significantly on the fixation process, solder paste selection, printing, and reflow soldering parameters. Carefully managing these aspects and monitoring production processes minimizes defects, ensuring high-quality SMT production with defect rates controlled within acceptable limits.SMT is the most popular technology and process in the flex PCB assembly industry

Leave A Comment