Printed Circuit Assembly Services: Comprehensive Guide

Introduction to PCBA Assembly

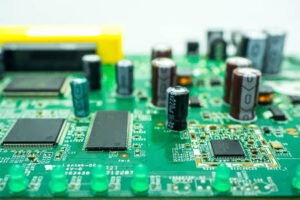

Printed Circuit Board Assembly (PCBA) involves the process of soldering or otherwise attaching electronic components to a printed circuit board (PCB) to create a fully functional electronic module or product. This process typically includes steps such as Surface Mount Technology (SMT) and Dual In-line Package (DIP) insertion.

PCBA Assembly Services

Component Preparation

Based on the designed circuit board schematics and the customer’s Bill of Materials (BOM), the necessary electronic components are prepared. This involves selecting suitable components from inventory or procuring them from suppliers as needed.

SMT Placement

Using specialized SMT equipment and techniques, we precisely place tiny electronic components onto the designated positions on the PCB. This process generally includes solder paste printing, component placement, and reflow soldering.

DIP Insertion

For larger components that cannot be placed using SMT, such as certain connectors and sockets, manual or semi-automatic insertion is employed using DIP techniques.

Soldering and Fixation

Wave soldering, selective soldering, or other soldering methods securely connect the components to the PCB.

Cleaning and Coating

We clean the PCB to remove residues from the soldering process. If necessary, we apply a protective coating to the PCB to enhance its resistance to moisture, dust, and corrosion.

Preliminary Functional Testing

After we assemble the PCB, we conduct initial functional testing to ensure all components are correctly installed and operational.

Additional Services

PCB Design Optimization

Based on customer requirements and product design specifications, we optimize the PCB layout and routing to enhance product performance and reliability.

Component Procurement Management

We are assisting customers in procuring necessary electronic components and effectively managing inventory to ensure smooth production.

Final Product Testing and Quality Assurance

Comprehensive functional testing and quality inspection of assembled electronic modules or products to ensure they meet design specifications and customer standards.

After-Sales Service and Support

We are providing technical support and after-sales service to address any issues encountered during the product’s usage.

Functionality of Printed Circuit Assemblies

Printed Circuit Assemblies (PCAs) are crucial in forming functional electronic circuits by mounting and soldering all necessary electronic components onto PCBs. The assembly process, also known as PCB assembly, is a critical step in electronics manufacturing. PCAs provide a coordinated platform for electronic components to work together, enabling the device to perform its intended functions.

In technical terms, PCAs serve as electrical interconnections, routing signals between components according to the schematic of the device. They also provide necessary grounding layers, voltage layers, and impedance control to ensure stable electrical performance.

The assembly process involves placing and soldering components such as resistors, capacitors, integrated circuits, and connectors onto the PCB. Depending on the component type and device design requirements, techniques like through-hole soldering and SMT can achieve this. After securely connecting the components to the PCB, we conduct functional, quality, and reliability testing on the assembled boards before integrating them into the final product.

Various factors, including component quality, assembly process accuracy, and solder joint integrity, influence the performance of a PCA. These factors affect the board’s electrical characteristics, such as resistance, capacitance, and inductance, as well as overall reliability and lifespan. Therefore, careful component selection, adherence to best assembly practices, and thorough testing are essential to ensure optimal performance and reliability of the final electronic device.

Conclusion

The assembly phase within Printed Circuit Assembly Services is a crucial part of the electronics manufacturing process, encompassing a series of steps from component preparation to preliminary functional testing. By providing comprehensive, efficient one-stop services, companies can help customers reduce production costs, improve product quality, and enhance market competitiveness.

Leave A Comment