Challenges and Opportunities in the Flexible PCB Industry

Introduction

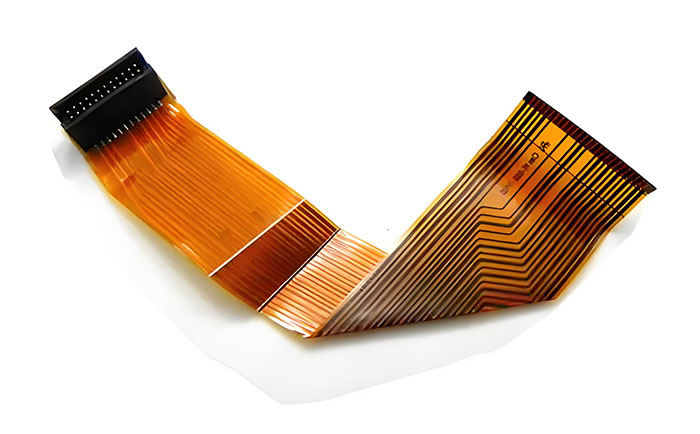

The flexible PCB industry (Printed Circuit Board)is a dynamic and rapidly evolving sector within the broader electronics market. Flexible PCBs, are essential components in various modern electronic devices due to their unique ability to bend and flex, enabling innovative design possibilities and advanced functionality. However, as with any technology-driven industry, the flexible PCB sector faces challenges and opportunities that shape its development and growth.

Overview of the Flexible PCB Industry

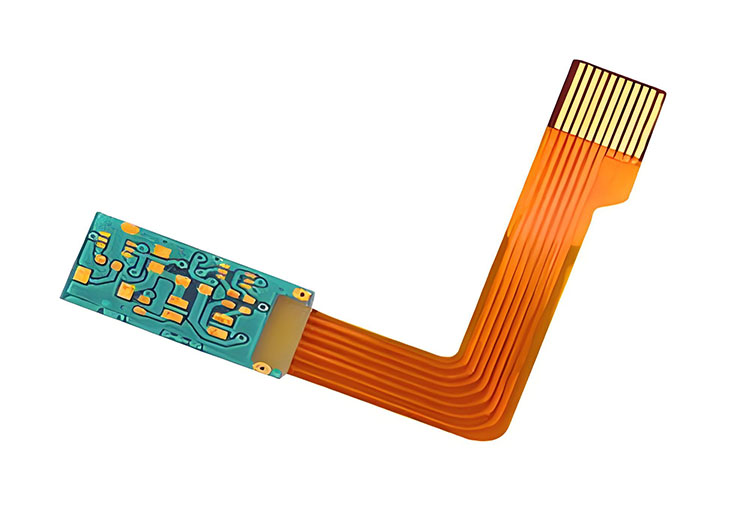

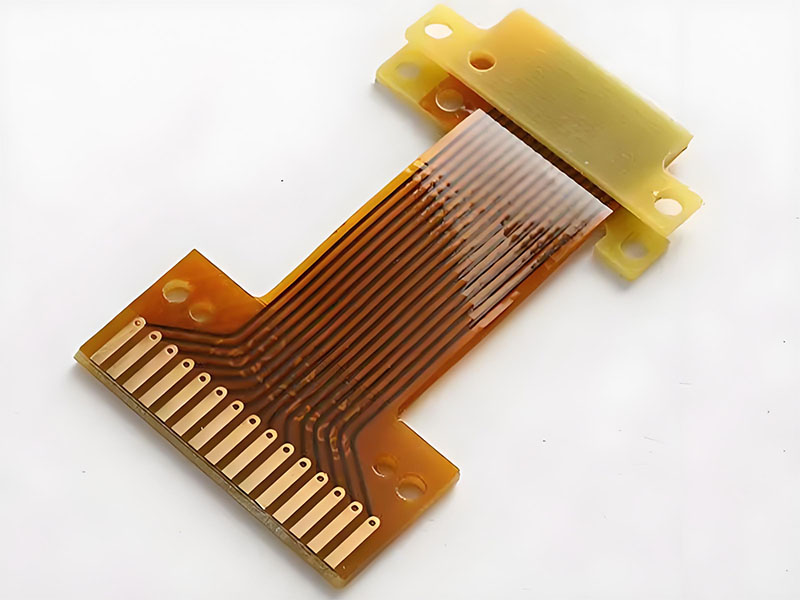

Flexible PCBs are characterized by their ability to conform to complex shapes and their use in applications where traditional rigid PCBs would be unsuitable. This flexibility allows for compact, lightweight, and durable electronic devices, making flex PCBs a critical component in consumer electronics, automotive, medical devices, and wearables. The global flexible PCB market is experiencing significant growth, driven by increasing demand for compact and reliable electronic devices.

Major Challenges in the Flexible PCB Industry

Material Limitations

One of the primary challenges in the flexible PCB industry is the limitation of materials used in their construction. Flexible PCBs require materials that can withstand repeated bending and flexing without losing their electrical integrity. The selection of appropriate substrates, such as polyimide or polyester, is crucial, but these materials can be expensive and sometimes challenging to work with due to their mechanical properties.

Manufacturing Complexity

Manufacturing flexible PCBs involves a more complex process compared to traditional rigid PCBs. The need to accommodate bending and flexing requires precise control over the production process. This complexity often leads to higher defect rates and lower yields, increasing production costs and time. Additionally, the assembly of components onto flexible substrates requires specialized techniques and equipment, further complicating the manufacturing process.

Cost Factors

The production of flexible PCBs can be cost-prohibitive due to the high cost of materials, specialized manufacturing processes, and lower yields. These factors contribute to higher overall costs compared to rigid PCBs, making it challenging for manufacturers to offer competitive pricing. This cost challenge is particularly significant for small and medium-sized enterprises (SMEs) looking to enter the flexible PCB market.

Reliability and Durability

Ensuring the reliability and durability of flexible PCBs is another critical challenge. The nature of flexible PCBs, which are designed to bend and flex, subjects them to mechanical stress that can lead to issues such as delamination, cracking, and electrical failures. Manufacturers must implement rigorous testing and quality control measures to ensure that their products can withstand the demanding conditions of their intended applications.

Environmental Concerns

Environmental sustainability is a growing concern in the electronics industry, and the flexible PCB sector is no exception. The use of certain chemicals and materials in the production of flex PCBs can have negative environmental impacts. Additionally, the disposal and recycling of flexible PCBs pose challenges due to their complex construction. Manufacturers are increasingly seeking eco-friendly materials and processes to mitigate these environmental concerns.

Opportunities in the Flexible PCB Industry

Technological Advancements

Advancements in materials science and manufacturing technologies present significant opportunities for the flexible PCB industry. Innovations such as advanced substrates, conductive inks, and additive manufacturing techniques are enabling the production of more reliable and cost-effective flexible PCBs. These technological developments are expected to enhance the performance and reduce the production costs of flex PCBs, making them more accessible to a broader range of applications.

Growing Demand in Consumer Electronics

The consumer electronics market continues to drive the demand for flexible PCBs. Devices such as smartphones, tablets, and wearable electronics require compact and flexible circuits to achieve their slim profiles and advanced functionalities. The increasing consumer demand for smaller, lighter, and more powerful electronic devices creates a substantial opportunity for the flexible PCB industry to expand its market presence.

Expansion in Automotive and Medical Sectors

The automotive and medical sectors are rapidly adopting flexible PCB technology due to its unique advantages. In the automotive industry, flexible PCBs are used in advanced driver-assistance systems (ADAS), infotainment systems, and sensor applications. The medical sector utilizes flexible PCBs in diagnostic equipment, wearable health monitors, and implantable devices. The growth of these sectors presents significant opportunities for flexible PCB manufacturers to diversify their applications and increase their market share.

Innovations in Wearable Technology

Wearable technology is a burgeoning field with immense potential for flexible PCBs. Devices such as smartwatches, fitness trackers, and smart clothing rely on flexible circuits to provide comfort, durability, and advanced functionality. The continuous innovation in wearable technology is driving the demand for flexible PCBs, offering manufacturers an opportunity to develop specialized products tailored to this market.

Strategic Partnerships and Collaborations

Collaborations between flexible PCB manufacturers, material suppliers, and technology companies can drive innovation and address industry challenges. Strategic partnerships can lead to the development of new materials, manufacturing processes, and applications for flexible PCBs. By working together, industry players can leverage each other’s strengths and resources to create more robust and cost-effective solutions.

The Role of Gekun in Addressing Challenges and Leveraging Opportunities

Gekun is at the forefront of the flexible PCB industry, continuously innovating to overcome challenges and seize opportunities. With a focus on advanced materials and cutting-edge manufacturing techniques, Gekun is developing flexible PCBs that meet the highest standards of reliability and performance. The company collaborates with key industry players to drive technological advancements and create solutions that address the specific needs of various sectors, including consumer electronics, automotive, and medical devices. By prioritizing sustainability and quality, Gekun is positioning itself as a leader in the flexible PCB market, delivering products that enable the next generation of electronic devices.

Conclusion

The flexible PCB industry is poised for significant growth, driven by advancements in technology and increasing demand across various sectors. While the industry faces several challenges, including material limitations, manufacturing complexity, and cost factors, the opportunities presented by technological advancements, growing consumer electronics demand, and expansion into new markets are substantial. Companies like Gekun are leading the way in addressing these challenges and leveraging opportunities to deliver innovative and reliable flexible PCB solutions. As the industry continues to evolve, the flexible PCB market is set to play a crucial role in the future of electronics, enabling the development of more advanced, compact, and flexible devices.

Leave A Comment