Revolutionizing Long-Distance Connectivity: The Role of Flexible Circuits in Modern Electronics

Introduction

Flexible circuits are transforming the way we approach long-distance connectivity in electronics. In industries like automotive, medical devices, and industrial automation, these circuits provide a unique solution where traditional rigid PCBs fall short. By offering both flexibility and reliability, long-flex circuits address the need for space efficiency and durable, high-performance connections over extended distances.

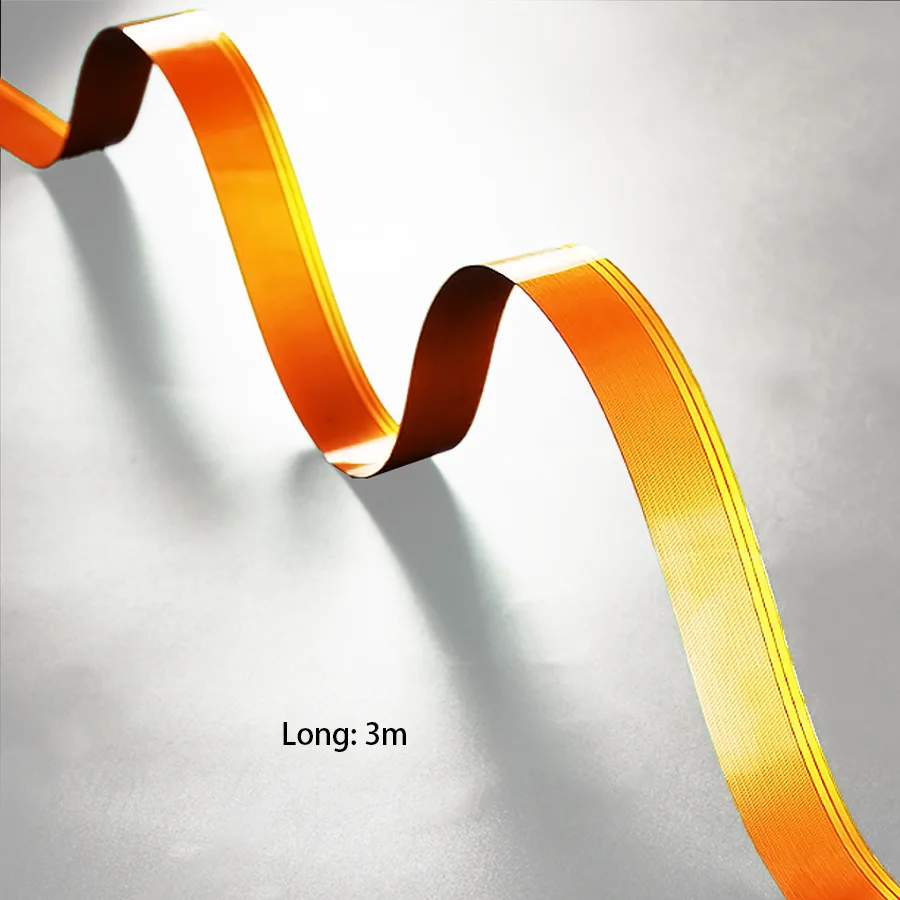

Why Long-Flex Circuits Matter

Long-flex circuits are engineered to deliver seamless connectivity across long distances. Their flexibility makes them ideal for use in tight spaces where rigid designs wouldn’t work. These circuits maintain signal integrity and support reliable performance even in challenging environments where movement or vibration is frequent.

Compact Design for Limited Space

Many modern devices, particularly in automotive and medical applications, require compact components. Long-flex circuits are highly efficient in these designs, as they save space while connecting electronic components across long distances.

Durability for Tough Environments

These circuits can endure repeated bending without losing performance. This makes them perfect for use in environments where vibrations or mechanical stress are common, such as in automotive or industrial machinery.

Reliable Signal Transmission Over Distance

Unlike traditional circuits, long-flex circuits maintain strong electrical connections over long distances. This ensures that devices stay connected and communicate effectively, whether in a car, a medical device, or an industrial control system.

Tailored to Fit Specific Needs

Engineers can customize these circuits to meet exact specifications. Whether single-layer, double-layer, or multi-layer, long-flex circuits can be designed for various requirements. The flexibility of design allows them to adapt to different configurations and ensure reliable performance.

Key Applications of Long-Flex Circuits

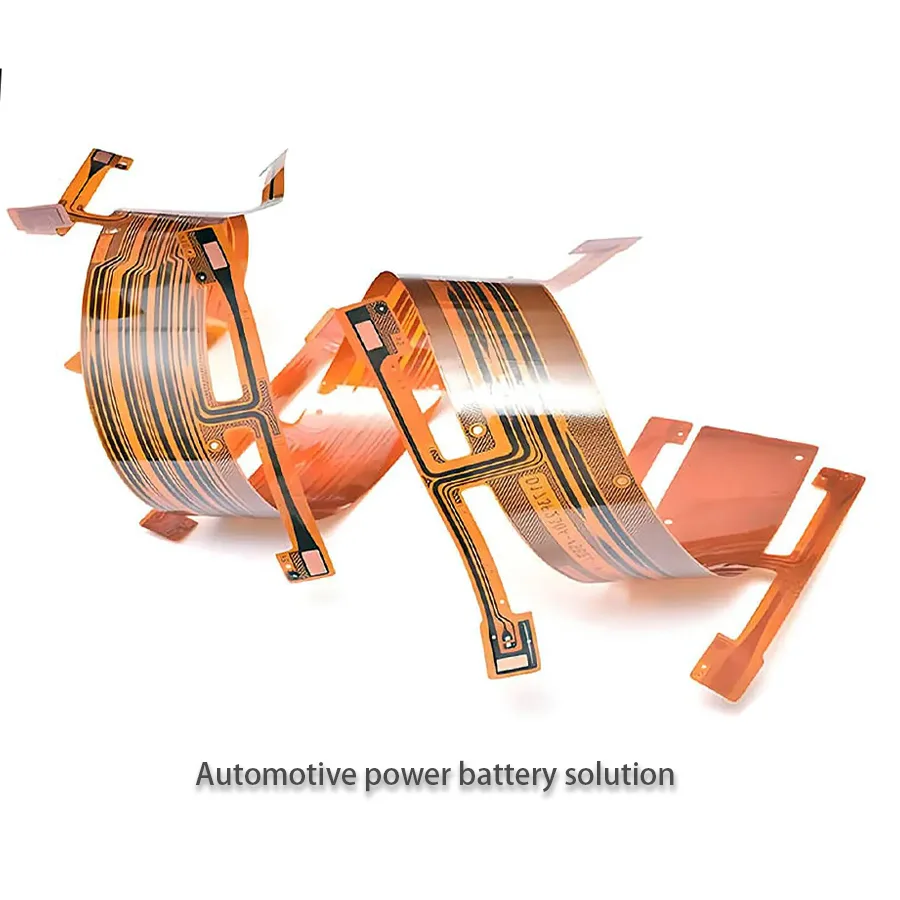

Automotive Electronics

In the automotive industry, long-flex circuits are used in a variety of applications, such as connecting sensors, power systems, and control units. These circuits ensure efficient connectivity even in the most space-constrained and vibration-prone areas.

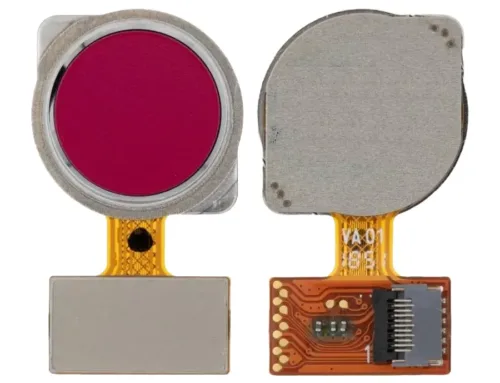

Medical Devices

Portable medical equipment requires compact and flexible solutions. Long-flex circuits are used in devices such as wearable health monitors, diagnostic tools, and other medical devices where both space efficiency and reliability are essential.

Industrial Automation

In industrial automation, long-flex circuits play a crucial role in connecting machines and control systems across large factory floors. They ensure seamless communication between sensors, actuators, and controllers, facilitating the smooth operation of complex machinery.

Advantages of Long-Flex Circuits

Maximized Space Efficiency

These circuits save valuable space within a device. Their ability to fit into compact areas allows manufacturers to create smaller, more efficient products.

Cost-Efficiency in Manufacturing

Long-flex circuits help reduce production costs by eliminating the need for complex wiring and connectors. Their simple design ensures reliability and reduces maintenance costs over time.

Eco-Friendly Design

These circuits are made from materials that comply with environmental standards such as RoHS, ensuring minimal environmental impact.

Conclusion

Flexible long-distance circuits are a game-changer in modern electronics. Their ability to connect components over extended distances while offering flexibility and durability makes them indispensable in industries like automotive, medical, and industrial automation. These circuits are enabling the development of smaller, more efficient, and more reliable devices. As technology continues to advance, the demand for flexible, long-distance connectivity solutions will only grow.

Leave A Comment