Flexible PCB board introduction: Basic principles and benefits

introduction

With the increasing prevalence of flexible PCBs in modern electronics and the growing application of rigid-flex PCBs, understanding the basics of flexible circuit boards is essential. Typically, PCBs made from flexible insulating substrates are referred to as flexible PCBs or flex circuits, while those combining both rigid and flexible elements are known as rigid-flex PCBs. These technologies are pivotal in advancing the miniaturization, lightweight design, and high reliability of electronic devices, all while meeting stringent economic and competitive market demands. In this article, we will explore the various types of flexible PCB boards, their advantages and disadvantages, and the critical role they play in modern electronics.

Classification and Characteristics of Flexible PCBs

1. Types of Flexible PCBs

Flexible PCBs are typically categorized based on the number of conductor layers and their structure:

1.1 Single-Sided Flexible PCBs

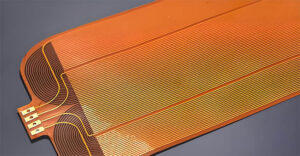

Single-sided flexible PCBs consist of one layer of conductors, which may or may not have a cover layer. The choice of insulating substrate material varies depending on the application, with common materials including polyester, polyimide, PTFE, and flexible epoxy-glass fabrics.

Single-sided flexible PCBs can be further divided into the following types:

Without Cover Layer, Single-Sided Connection: These are the most basic and cost-effective flex circuits, commonly used in non-critical, environmentally protected applications. Connections are typically made using soldering, welding, or crimping. An example application is early telephone systems.

With Cover Layer, Single-Sided Connection: This type adds a cover layer over the conductors for protection, leaving solder pads exposed as needed. This is the most widely used type of single-sided flexible PCB, prevalent in automotive dashboards and electronic instruments.

Without Cover Layer, Double-Sided Connection: These PCBs allow connections on both sides of the conductors. To achieve this, holes are made in the insulating substrate, enabling soldering on both sides. This type is used in applications requiring components on both sides and where soldering is essential.

With Cover Layer, Double-Sided Connection: This type features a cover layer with through-holes, allowing connections on both sides while maintaining the cover layer’s protection. Made from two layers of insulating material and one conductor layer, these PCBs are used when insulation between layers and connections on both sides are required.

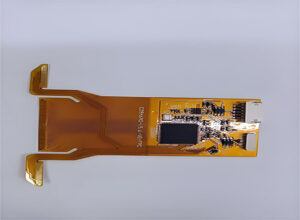

1.2 Double-Sided Flexible PCBs

Double-sided flexible PCBs have two conductor layers, offering the same benefits as single-sided flexible PCBs but with increased wiring density. These can be categorized based on the presence of metalized holes and cover layers:

-Without Metallized Holes, Without Cover Layer

– Without Metallized Holes, With Cover Layer

– With Metallized Holes, Without Cover Layer

– With Metallized Holes, With Cover Layer

PCBs without cover layers are less commonly used.

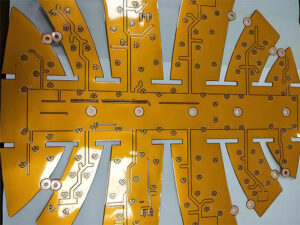

1.3 Multi-Layer Flexible PCBs

Like rigid multi-layer PCBs, multi-layer flexible PCBs are created using multi-layer lamination techniques. The simplest form is a three-layer flexible PCB with copper shielding on both sides of a single-sided PCB, providing electrical characteristics similar to coaxial or shielded cables. The most common structure is a four-layer PCB, with power and ground layers in the middle.

Multi-layer flexible PCBs offer the advantage of lightweight substrate films with excellent electrical properties, such as low dielectric constants. For example, multi-layer flexible PCBs made from polyimide films are about one-third lighter than rigid epoxy-glass PCBs. However, these PCBs lose the flexibility of single and double-sided flexible PCBs, and most applications do not require flexibility.

Multi-layer flexible PCBs can be further divided into the following types:

Flexible Insulating Substrate, Configured for Flexibility: These PCBs are designed to maintain flexibility, with single-sided or double-sided flexible circuits bonded together at the edges while the central part remains unbonded for maximum flexibility. Suitable for high-reliability, high-density designs requiring characteristic impedance matching, these PCBs use thin coatings instead of thick laminated cover layers.

Flexible Insulating Substrate, Not Configured for Flexibility: These PCBs are made from flexible materials but lose their inherent flexibility after lamination due to the required electrical design constraints. Applications requiring insulation properties, such as low dielectric constants and uniform thickness, benefit from these PCBs.

Flexible Insulating Substrate, Configured for Forming: These PCBs are formed into specific shapes and are not designed for continuous flexing. Ideal for aerospace, these PCBs offer low conductor resistance, minimal capacitance coupling, and smooth 90° bends at interconnections.

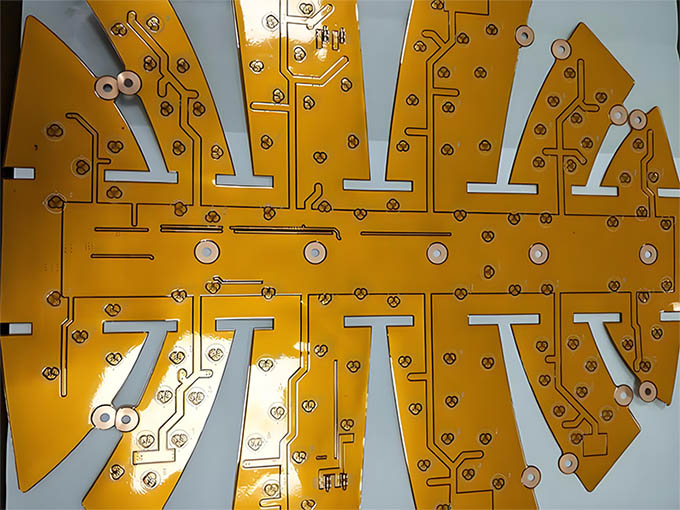

1.4 Rigid-Flex Multi-Layer PCBs

Rigid-flex multi-layer PCBs incorporate flexible PCB layers laminated within a rigid PCB structure to meet specific electrical or mechanical requirements. These PCBs are widely used in electronic devices where weight and volume are critical, and high reliability and electrical performance are essential.

Advantages of Flexible PCBs

2.1 Flexibility

One of the most significant advantages of flexible PCBs is their ability to facilitate wiring and connections in three-dimensional spaces, allowing them to be bent or folded as needed without damage, making them ideal for compact electronic designs.

2.2 Reduced Volume

Compared to traditional wiring, the flat, thin conductors of flexible PCBs reduce wiring size and allow for more compact and rational equipment design, saving 60-90% of space compared to rigid PCBs.

2.3 Weight Reduction

Flexible PCBs reduce weight by about 70% compared to wiring cables and 90% compared to rigid PCBs.

2.4 Consistent Connections

Using flexible PCBs eliminates errors common with manual wiring, ensuring consistent and error-free connections once the design is validated.

2.5 Increased Reliability

Flexible PCBs reduce the need for interconnections, enhancing overall system reliability and simplifying fault detection.

2.6 Controlled Electrical Parameters

Designers can control capacitance, inductance, impedance, delay, and attenuation when designing flexible PCBs, offering characteristics that are difficult to achieve with traditional wiring.

2.7 Solderable Ends

Flexible PCBs have terminal pads similar to rigid PCBs, eliminating the need for wire stripping and tinning, thereby reducing costs.

2.8 Material Flexibility

Flexible PCB board can be made from various substrate materials to meet different application requirements, such as cost-effective polyester films or high-performance polyimide films.

2.9 Cost Efficiency

Flexible PCBs reduce overall costs by ensuring consistent parameters, eliminating wiring errors, simplifying design, and enabling continuous production.

Disadvantages of Flexible PCBs

3.1 High Initial Cost

Flexible PCBs have higher initial design and photomask costs, making them less ideal for small-scale applications.

3.2 Difficulty in Modification and Repair

Once manufactured, flexible PCBs are challenging to modify or repair, as changes must begin from the photomask or CAD program. The protective cover layer adds complexity to repairs.

3.3 Size Limitations

Flexible PCB board is typically produced using batch processing, limiting their size due to manufacturing equipment constraints.

3.4 Risk of Damage from Improper Handling

Improper handling during assembly can easily damage flexible circuits, and rework requires trained personnel.

Conclusion

Flexible PCB board is an integral part of modern electronic design, offering numerous advantages in terms of flexibility, size, weight, and reliability. Despite their higher initial cost and challenges in modification, their benefits in specific applications outweigh these drawbacks. As the industry continues to evolve, the role of flexible PCBs, including the innovative solutions offered by brands like Gekunflex, will only expand, providing essential components for the next generation of electronic devices.

Leave A Comment