Global Space PCB Assembly Services Revolutionize Manufacturing

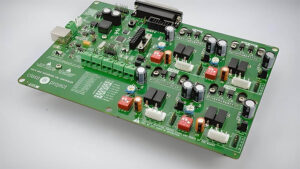

Overview of Global Space PCB Assembly Services

In the global landscape of electronic manufacturing, Global Space PCB Assembly Services play a critical role. This service is not only a fusion of technology and innovation but also a manifestation of global integration, linking the heart of the electronics industry to the pulse of the worldwide market.

The term “Global Space PCB Assembly Services” represents a manufacturing concept that transcends traditional geographic limitations. It encompasses the entire process chain from initial design to final product realization, including but not limited to precise manufacturing processes, global logistics networks, integrated supply chain solutions, and continuous technical support. The essence of this service model lies in its worldwide layout and resource integration capabilities, demonstrated in the following aspects:

1. Synergy of Global Networks: Service providers establish production bases and service centers in key global regions, creating an efficiently responsive global service network.

2. Deep Integration of Supply Chains: Through carefully designed supply chain strategies, global procurement of raw materials and components is achieved, optimizing cost structures and enhancing operational efficiency.

3. Frontline of Technological Innovation: Constantly introducing and applying cutting-edge PCB assembly technologies, such as micron-level precision placement and highly automated production lines, ensuring exceptional product quality and performance.

4. Flexible Custom Solutions: Offering customized service solutions tailored to individual customer needs to meet the diverse demands of the market.

As electronic products become increasingly diverse and complex, the demand for PCB assembly services is experiencing explosive growth. This is especially true in fields with high requirements for technical precision and reliability, such as aerospace, medical devices, and communication technology. PCB Assembly Services, with their professional, flexible, and forward-looking services, meet these high standards and drive technological advancements and market expansion across the electronics industry.

Evolution of PCB Assembly Technology

From Traditional Handcraft to Automation

The development of PCB assembly technology has evolved from meticulous handcrafting to the precise execution of automated systems. Early manual assembly, despite embodying craftsmanship, was limited by efficiency and consistency. As electronic technology rapidly advanced, automated assembly lines emerged, equipped with the latest robotic arms and visual recognition systems, completing a series of previously unimaginable complex tasks with extraordinary speed and accuracy.

Breakthroughs in High Precision and High Density

As electronic devices continue to move towards miniaturization and integration, PCB Assembly Services faces new challenges and opportunities. The advancement of high-precision assembly technology makes the accurate placement of micron-level components possible, while the application of high-density technology enables more functions to be integrated into limited space. These technological advancements not only enhance product performance but also significantly promote innovation in electronic devices.

Latest Technological Progress

Currently, Global Space PCB Assembly Technology stands at a new height. The application of nano-level positioning technology has achieved unprecedented assembly precision. The development of 3D assembly technology provides a new dimension for the design and manufacturing of electronic devices. Intelligent assembly systems, integrated with machine learning algorithms, achieve self-optimization, not only improving production efficiency but also continuously reducing resource waste during the production process.

Advantages of Global Space PCB Assembly Services

Global Space PCB Assembly Services, with their unique cross-regional service capabilities, have become the global link of the electronics manufacturing industry. The advantages of this service lie in its ability to transcend geographical boundaries and provide customized solutions for clients in different regions, meeting their specific needs for electronic product manufacturing.

Cross-Regional Service Capabilities

The core advantage of Global Space PCB Assembly Services lies in its cross-regional service capabilities. Service providers establish production bases and service centers worldwide, ensuring that clients can enjoy timely and efficient services regardless of their location. This global network layout not only shortens product delivery cycles but also increases customer satisfaction.

Flexible Supply Chain Management

Another significant advantage is flexible supply chain management. Global Space PCB Assembly Services can quickly respond to market changes and adjust procurement strategies for raw materials and components promptly through efficient supply chain integration. This flexibility allows service providers to take swift action during raw material shortages or market fluctuations, ensuring continuous production and stable product supply.

High-Quality Standards and Strict Quality Control

The high quality and strict quality control processes ensure the excellence of Global Space PCB Assembly Services. Service providers adhere to internationally recognized quality management systems, with stringent quality control at every stage, from raw material inspection to final product testing. This relentless pursuit of quality not only earns customer trust but also establishes the service provider’s leadership position in the industry.

Global Space PCB Assembly Services, with their cross-regional service capabilities, flexible supply chain management, and high standards of quality control, provide strong support for the development of the global electronics manufacturing industry, becoming a key service that connects the world’s electronic heart.

Case Studies in Industry Applications

Global Space PCB Assembly Services are becoming the core force driving technological advancement and improving product performance across the diversified applications of the global electronics industry. The following is an in-depth analysis of several key industry application cases, exploring the success factors and challenges involved.

Automotive Industry

The intelligence and electrification of the automotive industry are driving the growing demand for high-performance Electronic Control Units (ECUs). Global Space PCB Assembly Services demonstrate exceptional manufacturing capabilities in this context, producing durable PCB components that withstand high temperatures and vibrations. For instance, Eashub offers a one-stop supply chain service tailored for the automotive industry, ensuring that every stage from concept to finished product meets high efficiency and high standards.

Medical Device Industry

The medical device industry demands nearly stringent precision and reliability in PCB assembly. Global Space PCB Assembly Services utilize cutting-edge Surface Mount Technology (SMT) to ensure precise placement of micro-components, thus guaranteeing the stability and safety of medical devices.

Aerospace Industry

In the aerospace sector, where equipment stability is tested in extreme environments, Global Space PCB Assembly Services provides customized solutions that significantly enhance PCB radiation resistance and temperature durability through special materials and processes, meeting the stringent standards of the industry.

Communication Industry

With the rise of 5G technology, communication equipment demands higher density and faster signal transmission standards for PCB assembly. Global Space PCB Assembly Services, by adopting high-density assembly and high-speed signal optimization technologies, help manufacturers improve product performance, meeting the high requirements for speed and efficiency in the 5G era.

Success Factors

– Adherence to high-quality standards with internationally recognized management systems, ensuring that every detail of the production process is impeccable.

– Continuous technological innovation, including the introduction of automated production lines and machine learning algorithms, to enhance production efficiency and product quality.

– Providing customized services to meet the unique needs of different industries.

Challenges

– Rapid technological updates require continuous R&D investment to maintain competitiveness.

– Intense market competition necessitates standing out among many participants.

– Global supply chain management ensures the quality of raw materials and components and the continuity of supply.

Through an in-depth analysis of these cases, we recognize the key role of Global Space PCB Assembly Services in driving industry development and the challenges that must be faced and overcome to maintain competitiveness.

Future Trends in Global Space PCB Assembly Services

In the fast-evolving global electronics industry, Global Space PCB Assembly Services stands at the forefront of technological innovation. This section will explore how technological advances drive innovation in PCB assembly services and predict future market demand and industry development directions.

Technological Progress

Technological progress is the key factor driving innovation in PCB assembly services. With the development of automation and intelligent technologies, PCB manufacturing is moving towards higher efficiency and precision. For example, the introduction of automated production lines and robotic technologies not only reduces human intervention but also increases production efficiency. Meanwhile, the application of intelligent detection equipment and big data analysis technologies makes quality control in the production process more precise, continuously improving product yields.

Market Demand and Industry Development

As emerging technologies such as IoT, AI, and 5G develop rapidly, the demand for high-performance, high-reliability PCB products is increasing. This trend drives continuous innovation and progress in PCB manufacturing and assembly technology. For instance, to meet the demands of 5G communication equipment for high-speed, high-frequency circuit boards, low-loss high-frequency materials and processes have been developed.

Environmental Protection and Sustainability

Environmental protection and sustainability requirements are also pushing PCB manufacturing and assembly services towards greener practices. Examples include reducing the use of harmful chemicals, promoting lead-free soldering techniques, and improving material recycling rates.

Future Directions

PCB Assembly Services will continue to evolve towards intelligence, automation, and green practices. The further development of intelligent manufacturing technologies will make the production process more efficient, flexible, and personalized, better meeting the diverse needs of different customers. Meanwhile, the rise of global collaborative manufacturing models will make PCB manufacturing and assembly services more globalized, promoting technological exchange and cooperation between multinational companies and jointly driving the progress and development of the electronics industry.

Considerations for Choosing Global Space PCB Assembly Services

In the global electronics supply chain, choosing a reliable Global Space PCB Assembly Services provider is crucial for ensuring product quality and market competitiveness. Here are the key factors to consider when evaluating and selecting a service provider:

Technical Capabilities

The first consideration is the technical capabilities of the service provider. This includes whether they possess advanced PCB assembly technologies and automated production lines and whether they can handle high-density, high-precision assembly needs. Understanding their production equipment and process flows is also an important aspect of evaluating their technical capabilities.

Quality Assurance

Quality is the lifeline of PCB assembly services. A top-tier service provider should have a strict quality control system, such as ISO certification, and be able to provide comprehensive quality inspection services, including but not limited to Automated Optical Inspection (AOI), X-ray inspection, etc., ensuring that each product meets industry standards.

Cost-Effectiveness

While technical capabilities and quality are crucial, cost-effectiveness cannot be overlooked. Evaluate whether the service provider offers competitive pricing while considering the comprehensive costs, including logistics, tariffs, etc., in a global service context.

After-Sales Support

Reliable after-sales support is vital for the long-term cooperation between clients and service providers. Ensure that the service provider offers timely technical support and troubleshooting services, especially for multinational clients operating across different time zones.

Reputation and Experience

The reputation and experience of the service provider in the industry are important factors to consider. Look for reviews, case studies, and customer feedback to understand the provider’s performance history and reliability.

When choosing Global Space PCB Assembly Services, thoroughly evaluating the above aspects can help clients find a reliable, high-quality service provider, ensuring product success and market competitiveness.

Conclusion

In conclusion, PCB Assembly Services are at the heart of the electronics manufacturing world. Their role in connecting the globe, advancing technology, and ensuring the quality of electronic products is indispensable. By understanding the evolution of PCB assembly technology, the advantages of global services, and the importance of selecting the right provider. Businesses can leverage these services to drive innovation and maintain competitiveness in a rapidly evolving market. The future of electronics manufacturing is global, and Global Space PCB Assembly Services is leading the way.

Leave A Comment