Green PCB board gold and silver plating, which one is better?

Introduction

In the field of electronics manufacturing, the quality of a PCB directly impacts the performance and reliability of electronic products. Gold plating and silver plating are two common PCB surface treatment techniques, each with its merits in protecting the copper layer and improving soldering performance. This article delves into the differences between these two techniques and their impact on PCB performance.

The Oxidation Problem in PCBs

Copper Layer Oxidation Challenges: The copper layer on PCBs is prone to oxidation when exposed to air, reacting with oxygen and water vapor. This oxidation reduces the copper layer’s conductivity and affects the circuit’s performance.

The Protective Role of the Solder Mask

Introduction of the Solder Mask:

To protect the copper layer, engineers developed the solder mask—a special coating that forms a protective layer on the PCB surface, preventing the copper layer from coming into contact with the air.

Color Selection:

Solder mask colors vary, not only for aesthetic reasons but also to facilitate identification during manufacturing and maintenance.

Protection Strategies for Pads

Importance of Pads:

Pads are the parts of the PCB used for component soldering, and their protection is crucial. Oxidized pads can lead to difficult soldering and increased resistance.

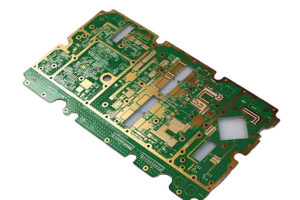

Comparison of Gold Plating and Silver Plating:

Gold plating and silver plating are effective protection measures. They prevent oxidation by covering the pads with an inert metal layer, ensuring good soldering quality.

Technical Differences Between Gold Plating and Silver Plating

Material and Performance Differences

Gold Plating: The Gold Standard for Conductivity and Corrosion Resistance

Gold plating enhances the conductivity and corrosion resistance of a PCB by applying a thin layer of gold on its surface, effectively preventing oxidation. Due to gold’s chemical stability, it is the preferred choice for high-end electronic products, especially in environments where long-term, stable performance is critical.

Silver Plating: A Cost-Effective Conductive Solution

Silver plating forms a silver layer on the PCB surface. Known for its excellent conductivity and relatively lower cost, silver plating is an economical option for improving PCB performance. Silver’s heat resistance makes it well-suited for high-temperature applications, such as high-power LED lights.

Visual and Aesthetic Considerations

Gold Plating: Luxurious Golden Sheen

Gold-plated PCBs exhibit a bright golden-yellow color, enhancing the visual appeal and quality of the product. This sheen is often regarded as a hallmark of high-end electronic devices.

Silver Plating: Practical Gray Tones

In contrast, silver-plated PCBs display a grayish-white or dark gray color, aligning more with a practical design philosophy. This aesthetic is suitable for applications where performance is prioritized over appearance.

Comparison of Applications and Characteristics

Gold Plating: The Golden Choice for High-End Electronics

Gold plating is favored in electronics with stringent requirements for quality and reliability, such as high-speed data transmission devices and large-capacity storage solutions, thanks to its superior performance.

Silver Plating: Silver Guardian in High-Temperature Environments

For equipment that must operate reliably under high-temperature conditions, such as high-power LED lights, silver plating provides essential heat resistance, ensuring stability in extreme environments.

Advantages of Gold Plating:

Gold is a highly stable metal, resistant to oxidation, and provides long-term protection.

Characteristics of Silver Plating:

Silver has better conductivity than gold, but its oxidation resistance is inferior, requiring more frequent maintenance.

Considerations for Production and Storage

Impact of Storage Conditions:

Different metal coatings have different requirements for PCB storage time and conditions.

Vacuum Sealing Protection:

To minimize oxidation, PCBs are usually vacuum-sealed before delivery.

Pre-Soldering Inspection and Quality Assurance

Oxidation Level Testing:

Before components are soldered, manufacturers test the PCB’s oxidation levels to ensure high-quality products.

Impact of Metal Coatings on Heat Generation

Relationship Between Resistance and Heat Generation:

Although gold and silver have low resistance, their minimal thickness on pads results in a negligible impact on heat generation.

Conclusion:

Both gold plating and silver plating are effective PCB protection techniques, each with its advantages in preventing oxidation and enhancing soldering performance. The choice of the appropriate plating technique depends on a combination of factors, including cost, performance requirements, and maintenance conditions. Through careful design and strict quality control, long-term stable operation of PCBs can be ensured.

Leave A Comment