Printed Circuit Assembly function and characteristics

introduction

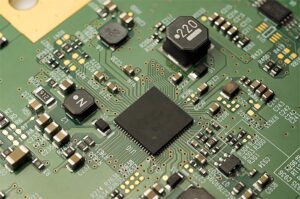

In the field of electronics manufacturing, PCBA (Printed Circuit Board Assembly) is a well-known term. As a core component of electronic products, PCBA plays a crucial role in realizing the functionality of electronic devices. So, what exactly are the roles and characteristics of PCBA?

The Role of PCBA

1. Enabling Circuit Connectivity and Functionality:

PCBA serves as the carrier for electronic components, connecting various components precisely through conductive traces on the Printed Circuit Board (PCB) to form a complete circuit system. According to design requirements, this system can perform specific electronic functions, such as signal processing, power management, and data transmission.

2. Simplifying the Assembly Process of Electronic Products:

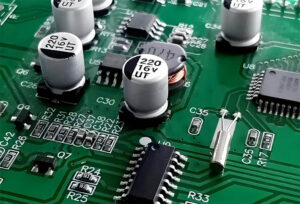

Before the advent of PCBA, assembling electronic products often required manual soldering of numerous components and wires, which was inefficient and prone to errors. PCBA, through automated surface-mount technology (SMT), accurately mounts components onto the PCB, greatly simplifying the assembly process and improving production efficiency.

3. Enhancing the Reliability and Stability of Electronic Products:

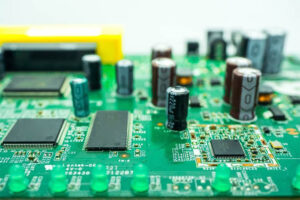

PCBA is manufactured with high precision and quality materials, ensuring stable and reliable circuit connections. Additionally, with well-thought-out layout and routing designs, PCBA effectively reduces issues like electromagnetic interference (EMI) and signal attenuation, thereby enhancing the overall performance of electronic products.

The Characteristics of PCBA

1. High-Density Integration:

PCBA allows for high-density integration of components, enabling electronic products to become more powerful even as their size continues to shrink. This is made possible by the fine circuit designs on the PCB and advanced surface-mount technology, which reduces the spacing between components to the millimeter or even micrometer level.

2. Good Maintainability:

Despite its high level of integration, PCBA is typically designed with maintainability in mind. Through reasonable modular design and plug-in connections, it is easy to replace or repair specific modules in the event of a failure without needing to replace the entire PCBA.

3. Flexibility and Customization:

PCBA can be custom-designed according to different requirements. Whether it’s the circuit’s functionality, performance, or shape and size, it can be flexibly adjusted based on the customer’s specific needs. This flexibility and customization capability make PCBA widely applicable to various types of electronic products.

4. Cost-Effectiveness:

For mass production, PCBA offers significant cost-effectiveness. Automated production lines and efficient surface-mount technology can drastically reduce production costs. Additionally, due to its high reliability and stability, PCBA minimizes the cost of repairs and replacements.

conclusion

PCBA plays a critical role in electronic products, and its characteristics—such as high-density integration, good maintainability, flexibility, customization, and cost-effectiveness—make it indispensable in modern electronics manufacturing.

Leave A Comment