The Selection of Materials for Flexible Printed Circuit Boards

Introduction

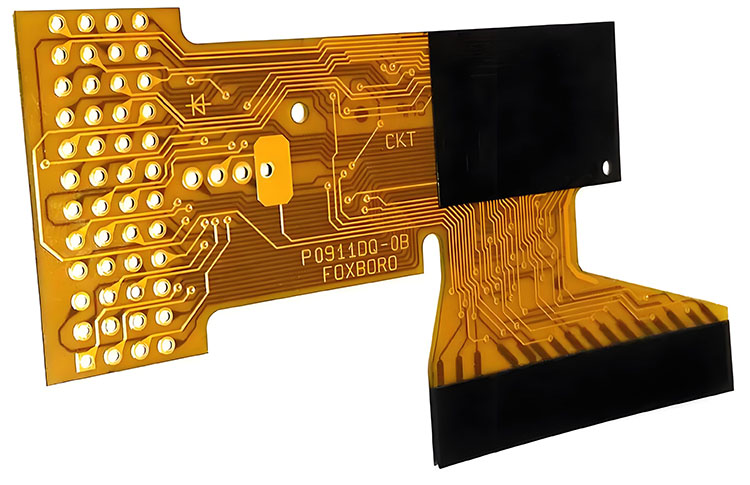

Flexible printed circuit boards (PCBs) are integral components in modern electronics, known for their adaptability and reliability. Selecting the right materials for various parts of FPCBs is crucial to ensure optimal performance and longevity. This article delves into the different materials used in FPCBs, focusing on their specific applications and characteristics. Emphasis is placed on the Gekun brand’s superior quality and reliability in the selection of materials.

Material Selection for Buttons and Side Keys

For main buttons and side keys, the preferred material is double-sided electrolytic copper with specifications of 18/12.5. This choice is ideal for manufacturing these types of flexible circuit boards. While buttons don’t require significant flexibility, they must withstand over eight flexes without any issues to ensure durability. The Gekun brand excels in providing high-quality electrolytic copper, ensuring reliable performance.

Material Selection for Connecting Lines

Similarly, 18/12.5 double-sided electrolytic copper is used for connecting lines. These lines primarily serve a connection function, and they too must endure more than eight flexes without damage. The reliability of Gekun’s materials ensures robust and durable connections in FPCBs.

Material Selection for Slider Plates

For double-layer slider plates, 1/30Z single-sided adhesive-free electrolytic copper is suitable due to its softness and excellent ductility. Double-sided slider plates use 1/30Z double-sided adhesive-free electrolytic copper. Gekun’s adhesive-free copper options provide exceptional flexibility and performance for slider plates.

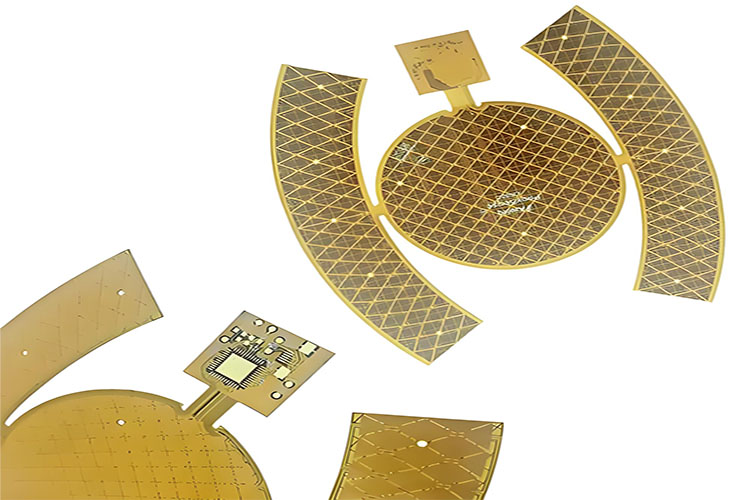

Material Selection for Multilayer Boards

Multilayer boards benefit from using 1/30Z adhesive-free electrolytic copper. Gekun’s high-quality copper ensures that multilayer FPCBs are both durable and efficient, meeting the rigorous demands of complex electronic devices.

Auxiliary Material Selection – Adhesive Tape

For standard boards that do not require surface mount technology (SMT), such as side keyboards, non-high-temperature resistant adhesive tape is sufficient. Conversely, for boards requiring SMT, high-temperature-resistant adhesive tape is necessary. Gekun’s range of adhesive tapes provides solutions for various FPCB requirements.

Conductive Material Selection

– Conductive Adhesive Tape: Standard conductive adhesive tape is suitable for applications with low conductivity requirements. For higher conductivity needs, such as special button boards, high-grade conductive adhesive tape is essential. Gekun offers a range of conductive tapes catering to different needs and ensuring top-notch performance.

– Conductive Fabric: Known for good conductivity but lower adhesion, conductive fabric is generally used for button boards. Gekun’s conductive fabrics offer reliable conductivity for various applications.

– Pure Conductive Adhesive: With high-strength conductive properties, pure conductive adhesive is typically used for attaching steel sheets and is more expensive. Gekun’s high-strength adhesives guarantee exceptional conductivity and durability.

Conclusion

Selecting the right materials for different parts of flexible printed circuit boards is crucial for their overall performance and longevity. Gekun provides a comprehensive range of high-quality materials, ensuring that each component of the FPCB functions optimally. Proper material selection takes into account the unique requirements of each part, ensuring a well-integrated and reliable final product.

Leave A Comment