Flexible PCB Manufacturing: Fourteen Essential Characteristics

Introduction

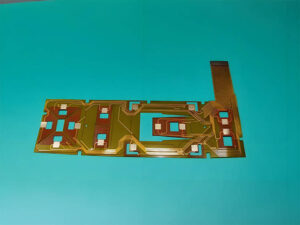

In the quest for portability and innovation in the electronic world, “bendable circuit boards” stand out with their flexible properties. These high-tech circuit boards not only adapt to various shapes but also provide designers with limitless creative space. They are lightweight, durable, and compatible with multiple materials, signaling a future where electronic devices will be more personalized and comfortable. With continuous technological advancements, flexible pcb manufacturing” is leading an electronic revolution, making our devices smarter and more integral to our lives.

Fourteen Key Features of High-Reliability Flexible PCB Manufacturing

FPC flexible circuit boards may appear similar on the surface, regardless of their internal quality. It is through this surface that differences become apparent, which are crucial for PCBs’ durability and functionality throughout their lifespan.

Whether in the manufacturing assembly process or actual use, reliable performance of PCB circuit boards is critical. Beyond associated costs, defects during the assembly process can lead to failures in the final product, potentially resulting in claims. From this perspective, it can be stated without exaggeration that the cost of a high-quality PCB is negligible. In all market segments, particularly those producing products for critical applications, the consequences of such failures can be dire.

When comparing FPC circuit board prices, it is essential to keep these aspects in mind. While the initial costs of reliable, guaranteed, and long-lasting products may be higher, they are worth the investment in the long run. Below are the fourteen most important features of high-reliability circuit boards:

25 Micron Copper Thickness for Hole Walls

Benefit: Enhances reliability, including improved Z-axis expansion resistance.

Risk of Not Doing This: Risks of blow holes or air removal, electrical connectivity issues during assembly (inner layer separation, hole wall breakage), or failures under load conditions during actual use. IPC Class 2 specifies a 20% lower copper plating requirement.

No Solder Repairs or Circuit Repair Wires

Benefit: Perfect circuits ensure reliability and safety with no repairs and no risks.

Risk of Not Doing This: Improper repairs can cause the circuit board to open circuits. Even if repairs are done “correctly,” risks of failure under load conditions (vibration, etc.) persist, potentially leading to failures during actual use.

Cleanliness Requirements Exceeding IPC Standards

Benefit: Improved PCB cleanliness enhances reliability.

Risk of Not Doing This: Residues and solder accumulations on the circuit board pose risks to the solder mask, while ionic residues can lead to corrosion and contamination of solder surfaces, ultimately increasing the likelihood of reliability issues (poor solder joints/electrical failures) and actual failures.

Strict Control of Each Surface Treatment’s Lifespan

Benefit: Improved solderability, reliability, and reduced risk of moisture intrusion.

Risk of Not Doing This: Old circuit board surface treatments may undergo metallurgical changes, leading to solderability issues, while moisture intrusion can cause delamination, inner layer, and hole wall separation (open circuits) during assembly and/or actual use.

Use of Internationally Recognized Substrates—Avoiding Local or Unknown Brands

Benefit: Enhances reliability and known performance.

Risk of Not Doing This: Poor mechanical performance means the circuit board may not perform as expected under assembly conditions, such as high expansion leading to delamination, open circuits, and warping issues. Degraded electrical properties can lead to poor impedance performance.

Copper Foil Tolerance Meets IPC4101 Class B/L Requirements

Benefit: Ensures compliance with electrical performance standards.

Risk of Not Doing This: Electrical performance may fail to meet specifications, leading to significant variations in output/performance among components from the same batch.

Define Solder Mask Materials to Ensure Compliance with IPC-SM-840 Class T Requirements

Benefit: “Excellent” ink ensures the safety and compliance of solder mask inks with UL standards.

Risk of Not Doing This: Poor-quality inks can lead to adhesion, solvent resistance, and hardness issues, all of which can cause the solder mask to separate from the circuit board, resulting in copper circuit corrosion. Poor insulation characteristics can lead to accidental electrical connectivity/arc-induced shorts.

Define Tolerances for Shapes, Holes, and Other Mechanical Features

Benefit: Strict control of tolerances improves product dimensional quality—enhancing fit, shape, and functionality.

Risk of Not Doing This: Problems during assembly, such as alignment/fit issues (only noticeable once assembly is completed). Additionally, size deviations can complicate insertion into bases.

Specify Solder Mask Thickness Requirements, Even Though IPC Has No Related Provisions

Benefit: Improves electrical insulation characteristics, reduces risks of peeling or loss of adhesion, and strengthens resistance to mechanical shocks—regardless of where they occur!

Risk of Not Doing This: A thin solder mask can lead to adhesion, solvent resistance, and hardness issues, which can cause the solder mask to separate from the circuit board, leading to copper circuit corrosion. Poor insulation characteristics due to a thin solder mask can cause shorts from accidental conduction/arcing.

Define Appearance and Repair Requirements, Even Though IPC Has No Definitions

Benefit: Careful attention and diligence during manufacturing ensure safety.

Risk of Not Doing This: Various scratches, minor damages, repairs, and adjustments—while the circuit board may function, it may not look good. Besides visible surface issues, what unseen risks might affect assembly and pose risks during actual use?

Specify Requirements for Plug Hole Depth

Benefit: High-quality plug holes will reduce the risk of failure during assembly.

Risk of Not Doing This: Unfilled holes may retain chemical residues from the plating process, leading to solderability issues. Additionally, solder balls may be trapped in the holes, which could splash out during assembly or actual use, causing shorts.

Specify Brands and Models of Strippable Blue Adhesives

Benefit: Specifying strippable blue adhesive avoids the use of “local” or cheap brands.

Risk of Not Doing This: Poor-quality or cheap strippable adhesives may bubble, melt, crack, or solidify like concrete during assembly, making them ineffective or difficult to remove.

Implement Specific Approval and Ordering Procedures for Each Purchase Order

Benefit: Ensures that all specifications have been confirmed.

Risk of Not Doing This: If product specifications are not thoroughly confirmed, deviations may only be noticed during assembly or in the final product, by which point it may be too late.

Do Not Accept Assemblies with Scrap Units

Benefit: Avoiding partial assemblies helps clients improve efficiency.

Risk of Not Doing This: Assemblies with defects require special assembly procedures. If defective units (x-outs) are not clearly marked or isolated from assemblies, there is a risk of assembling known defective boards, wasting parts and time.

conclusion

The article discusses the significance of high-reliability flexible pcb manufacturing in the electronics industry, highlighting fourteen critical features that enhance their performance and durability. It emphasizes the importance of material quality, manufacturing processes, and design considerations in ensuring reliable PCB functionality. The article outlines the risks associated with subpar manufacturing practices and advocates for adherence to high standards to prevent failures, ensuring that FPCs meet the demanding requirements of various applications. Overall, it underscores the balance between cost and long-term value in producing quality FPCs.

Leave A Comment