Multilayer Flex PCB

As the name suggests, a Multilayer Flex PCB combines the characteristics of “multilayer” with those of “flexible.” It finds typical use in situations where space is limited, and there are specific electrical performance requirements. Increasing the number of flexible circuit layers achieves the desired design functionality.

Read on to learn more about Multilayer Flex PCBs.

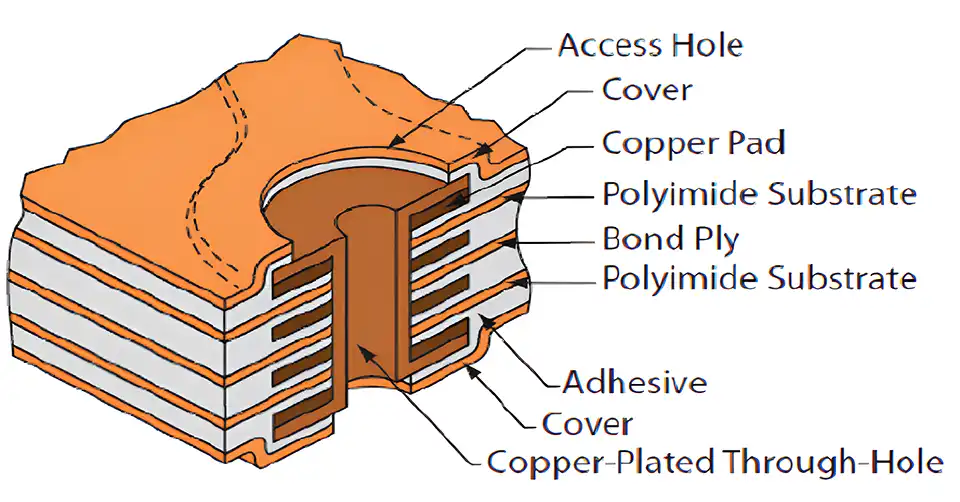

Structure diagram

When to Choose a Multilayer Flex PCB

Space Constraints

When to Choose a Multilayer Flex PCB Space Constraints Choose a multilayer design when double-sided circuits cannot meet the layout requirements due to limited space.

Electrical Performance Requirements

use Multilayer Flex PCBs in situations that require specific electrical performance, such as impedance control or interference shielding. Moreover, opt for Durability for Bending and choose these PCBs

Durability for Bending

When we design structures for rotation that need a long bending life — like in the case of flip phones or laptops — we normally have these structures survive for about 100,000 to 200,000 bends. To summarize, Multilayer Flex PCBs are a combination of “flexible” and “multilayer” PCBs. They provide high-precision, flexible, and reliable solutions, making them suitable for various advanced and complex electronic products and applications.

So essentially, Multilayer Flex PCBs are both “flexible” and “multilayer” designs.They provide high-precision, flexible, and reliable solutions, making them suitable for various advanced and complex electronic products and applications.

Types of Multilayer Flex PCB

Signal layer components are isolated from the power and ground planar layers in multilayer flex PCBs to reduce signal crosstalk, as well as to reduce EMI. This improvement enhances signal integrity and reliability, making them suitable for high-speed and high-frequency applications.

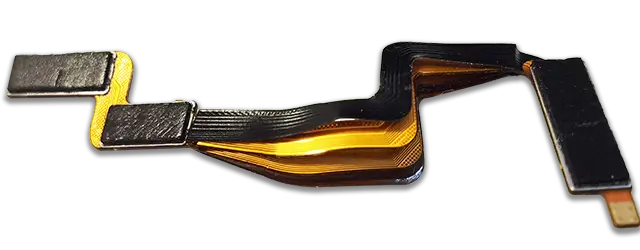

Stacked Multilayer

When high bending flexibility isn’t needed, we fix these PCBs within a housing. We add extra layers to meet wiring requirements when space is limited. Another use is adding a middle shielding layer to reduce interference and meet impedance needs.

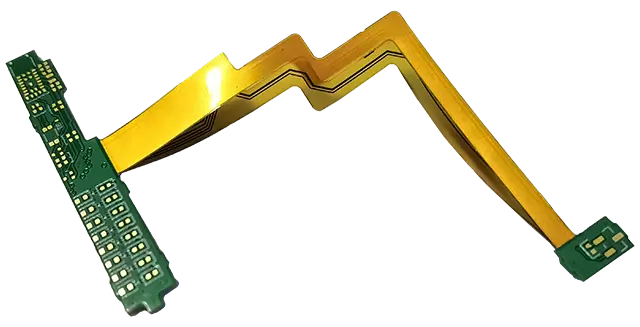

Unstacked Multilayer

Use these PCBs in applications where bending durability is required. To ensure flexibility, you can stack multiple single-sided circuit layers without adhesive between them. Then, bond specific areas to achieve electrical conductivity, while keeping the other parts flexible.

Rigid-Flex Multilayer PCB

These PCBs have multiple layers in both the rigid and flexible sections. They ensure the characteristics of both “rigid” and “flexible” while meeting the requirements of multilayer wiring.

Stacked

Unstacked

Rigid-Flex Multilayer PCB

Multilayer Flex PCB offers significant advantages:

- Increases Circuit Density

- Enhances Design Flexibility

- Improves Signal Integrity

- Saves Space and Lightweight

Can enhance Design Flexibility: Multilayer Flex PCBs offer greater design flexibility by stacking multiple circuit layers. Designers can route traces through different layers, reducing signal interference and optimizing integrity. This allows for more complex and intricate designs.

Can increased Circuit Density: Multilayer Flex PCBs have multiple circuit pattern layers, allowing for higher circuit density than single or double-sided boards. This means more components can fit into smaller spaces, enhancing functionality in a compact design.

In conclusion, choosing us for your custom Multilayer Flex PCB needs is the best decision!

Our Capabilities

Capabilities of multilayer flex PCB

In summary, if you have flexible circuit design or flexible printed circuit board needs, we can help.

Materials for Flexible circuits

Copper foil ——Flexible printed circuit boards (FPC)’s fundamental material is Copper foil. We press copper foil onto PI film to create the substrate, then etch it to form a conductive pattern, This allows the circuit to transmit signals and electricity efficiently.

——————————————————————————————————————————————————————————————-

Polyimide film—— It has good mechanical properties and high-temperature resistance,

and withstanding the deformation of flexible circuits during use, like bending and stretching, twisting. Additionally, well it maintains stability and reliability in high-temperature environments.

——————————————————————————————————————————————————————————————-

PI Stiffeners, Steel sheet Stiffeners, and FR4 Stiffeners are used in flexible circuits to enhance mechanical strength and stability. They act as supporting materials, laminated on one or both sides of the circuit board, providing extra support and stability. During use, PI Stiffeners reduce bending and twisting, minimizing damage and failure. Additionally, they offer extra protection, preventing damage and wear during operation.

——————————————————————————————————————————————————————————————-

In summary, if you have flexible circuit design or flexible printed circuit board needs, we can help.

Get A Quote

[fusion_form form_post_id=”5445″ hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” /]