Differences Between Rigid, Flexible, and flex rigid pcb

Introduction

Rigid PCBs are circuit boards built on rigid substrates that cannot bend, while flexible PCBs, also known as flex circuits, are built on flexible substrates that can bend. Both rigid and flexible printed circuit boards (PCBs) are used to guide the movement of current, connecting electronic components in various consumer and non-consumer products.

Rigid PCBs are relatively sturdier than flexible PCBs, but flexible circuits offer durability in terms of flexibility.

flex rigid pcb is a hybrid design that combines the properties of both rigid and flexible PCBs to form highly efficient boards that maximize the functional efficiency of various applications. By using both rigid and flexible materials, they provide added reliability and broader PCB functionality.

Rigid vs. Flexible PCBs: What’s the Difference?

Though rigid and flexible PCBs serve the same basic purpose of connecting electronic components in various devices, there are many key differences between them. Their manufacturing processes differ, as do their performance, advantages, and disadvantages. Below is a breakdown of their unique properties and functions:

Substrate:

Rigid boards use conductive traces and other elements arranged on a non-conductive substrate to connect electrical components. This non-conductive substrate usually contains glass, giving it strength and thickness. Flexible PCBs also have conductive traces on a non-conductive substrate, but they use flexible materials like polyimide.

Flexibility:

The substrate of rigid boards enhances their strength and rigidity. On the other hand, flexible PCBs use flexible bases that can bend to fit the required applications and can be folded into various shapes.

Conductors:

Rigid circuits typically use electrolytic copper as the conductive material, but because flexible circuits need to fold and bend, manufacturers may use more flexible rolled annealed copper.

Manufacturing Process:

The solder mask layer in rigid circuits is replaced in flexible PCB manufacturing by a process called overlay or overlay, which protects the exposed circuits of the board.

Cost:

Flexible circuits are generally more expensive than rigid circuit boards. However, because flex circuits can fit into compact spaces, manufacturers can create portable-sized products that are in high demand in consumer electronics, medical devices, space, and automotive applications. This ultimately brings more revenue and indirect savings for manufacturers.

Durability:

Both types of PCBs have a considerable degree of durability, but their performance differs. Rigid PCBs offer greater strength, while flexible materials allow PCBs to absorb vibrations better, dissipate heat, and withstand environmental factors. Flexible circuits can also be bent hundreds of thousands of times without failing.

Weight:

The strength and thickness of rigid PCBs make them slightly heavier than flexible PCBs, which are typically lighter. This feature is beneficial for the electronics industry, which frequently produces small devices requiring lighter components.

Resistance:

Flexible PCBs have high resistance to heat and extreme environments, making them less likely to succumb to these stresses. In contrast, rigid PCBs have lower resistance, making them more susceptible to damage or deformation due to heat, radiation, or chemicals.

Design Complexity:

For more basic consumer devices, such as toys or musical keyboards, rigid PCBs are ideal. However, flexible PCBs have more complex designs, making them suitable for highly sophisticated products.

The versatility of flexible circuits makes them widely used in compact and innovative electronics.

What is a Rigid-Flex PCB?

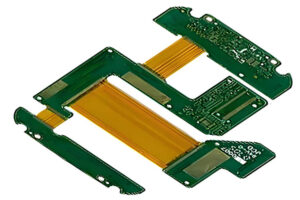

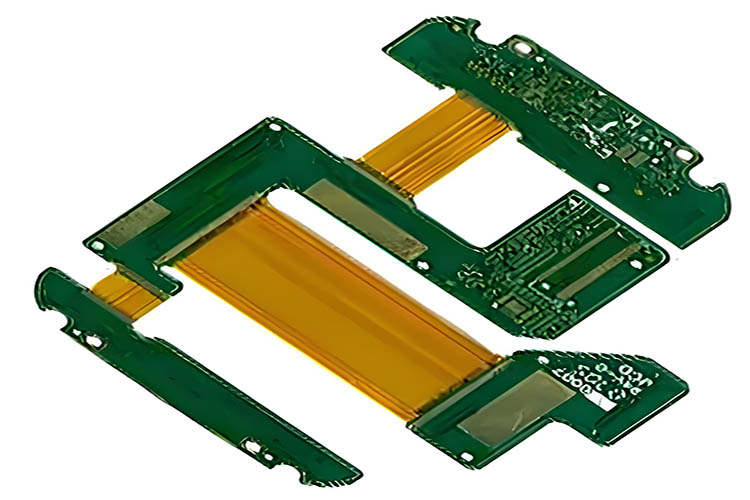

A flex rigid pcb design combines both rigid and flexible board technologies. In most rigid-flex boards, layers of flexible circuit substrates are attached to one or more rigid boards, either internally, externally, or both, according to the design specifications of the application. Typically, rigid flex pcb are manufactured with flexible polyimide materials bonded to rigid boards. The flexible portions of the rigid PCB usually have filled-through holes to ensure interconnection between layers.

Advantages

Rigid-flex boards offer numerous advantages, including lightweight construction, ease of assembly and repair, and enhanced reliability, performance, and flexibility in electronic devices. These and other benefits are discussed below:

Compact Size: As electronic devices become smaller and more flexible, the versatility of rigid flex PCB allows them to bend and fold to fit smaller devices, properly connecting miniature components. This miniaturization also makes them lightweight.

Increased Reliability:

The reduction in solder joints and board-to-board connectors also reduces the chances of connection impedance. Additionally, the rigid-flex board’s connections between rigid and flexible layers are solid and reliable, ensuring fewer circuit failures.

Space-Saving:

With built-in interconnecting circuits within the flexible substrate, rigid-flex PCBs offer more room for routing. This makes them ideal for compact designs as they require minimal space for wiring harnesses and high-profile connectors.

Cost-Effective:

Although rigid-flex boards are more expensive than standard rigid PCBs, they are more cost-effective in terms of assembly expenses. Because they are smaller and have fewer connections, less material is required for assembly. Fewer components and connector assemblies reduce procurement and assembly costs, increasing revenue. This means that rigid flex pcb significantly reduces overall manufacturing costs in assembly and logistics.

Ease of Testing:

Pre-interconnected sub-circuits in rigid-flex PCBs allow for easy automated testing. This testing enables manufacturers to eliminate connection problems before component assembly, preventing unnecessary waste and expense.

Design Flexibility:

With 3D design and multilayer flexible circuits, rigid-flex PCBs offer significant flexibility, allowing them to be installed in small devices. This flexibility means the device is no longer limited to specific PCB designs, as rigid-flex boards have impressive bend radii, enabling them to fit into various applications.

Resistant to High Temperatures and Harsh Conditions:

This type of PCB can withstand high temperatures due to the use of polyimide with high thermal stability. Additionally, combining the best features of rigid and flexible boards gives them excellent resistance to radiation, harmful oils and chemicals, extreme shock and vibration, and other harsh industrial conditions. This makes them ideal for devices that may be exposed to excessive movement and vibration during use.

Disadvantages

While rigid-flex boards have many advantages, they also come with notable drawbacks that manufacturers must weigh before investing. One key disadvantage is their lengthy and complex production process, requiring more financial and material resources to achieve a certain assembly speed, thereby driving up costs.

If design adjustments are required during testing, making changes to a rigid-flex board can be quite difficult, as it may require returning to the Gerber programming stage to correct errors. This results in increased expenses and time, as the design may need to be fully redone. Rigid-flex boards are also known for having a lower yield rate.

Applications of Rigid-Flex PCBs

The combination of features and functional advantages, such as reduced interface connections, minimized package weight and size, and resistance to extreme conditions, makes rigid-flex boards widely sought after in various commercial, industrial, and household applications. Besides being used in small consumer products like phones and multimedia players, they are used in the following industries:

Medical Industry:

Devices like pacemakers, cochlear implants, handheld monitors, imaging equipment, drug delivery systems, and wireless controllers.

Aerospace:

Production of radar equipment, GPS, radio communication systems, control tower systems, sensors, noise and vibration testing systems, motion sensors, and environmental and climate test chambers.

Telecommunications:

Base stations, handheld devices, communication satellites, wireless communication systems, signal processing systems, transmission media, routers and servers, and online signal expansion systems.

Consumer Appliances:

Common applications include ovens, TV remotes, washing systems, lighting systems, solar systems, UV water purifiers, electronic irons, and more.

Automotive:

The automotive industry applies flex rigid pcb technology in electronic control modules, transmission control, LCDs, and comfort control units, as well as air conditioning, music, traction control, entertainment, and navigation systems.

Military:

Significant applications in producing weapon guidance systems, communication systems, GPS, aircraft missile launch detectors, surveillance or tracking systems, etc.

Manufacturing:

In this field, flex rigid pcb boards are used in test equipment, electrical switches, industrial automation systems, control panels, industrial air conditioners, and CCTV monitoring systems.

Conclusion

The original rigid PCBs paved the way for technological advancements in circuit board design and electronic manufacturing, as seen with the emergence of flexible circuits and rigid-flex circuits. Each has its significance for specific device applications, with their respective properties and functions ensuring their continued relevance.

Leave A Comment