Differences Between FPC Flexible Circuit Boards and PCB Boards

Introduction

This article explores the distinctions between FPC flexible circuit boards and traditional PCB boards. It delves into the unique advantages of FPCs, such as flexibility, size and weight reduction, consistency in assembly, increased reliability, and more. It also addresses the disadvantages, including high initial costs, difficulty in modifications and repairs, size limitations, and susceptibility to damage. By the end of this article, readers will have a comprehensive understanding of when and why to choose FPC flexible circuit boards over traditional PCBs.

一、Advantages of FPC Flexible Circuit Boards

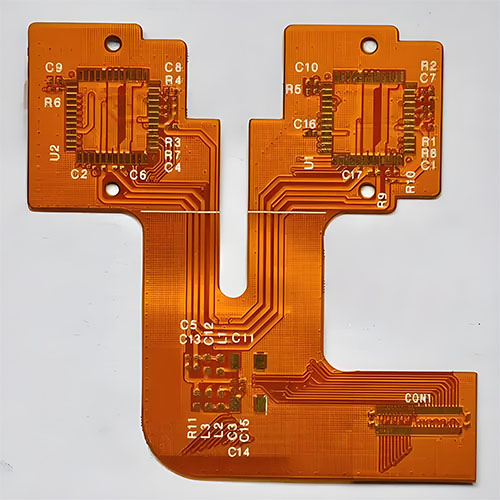

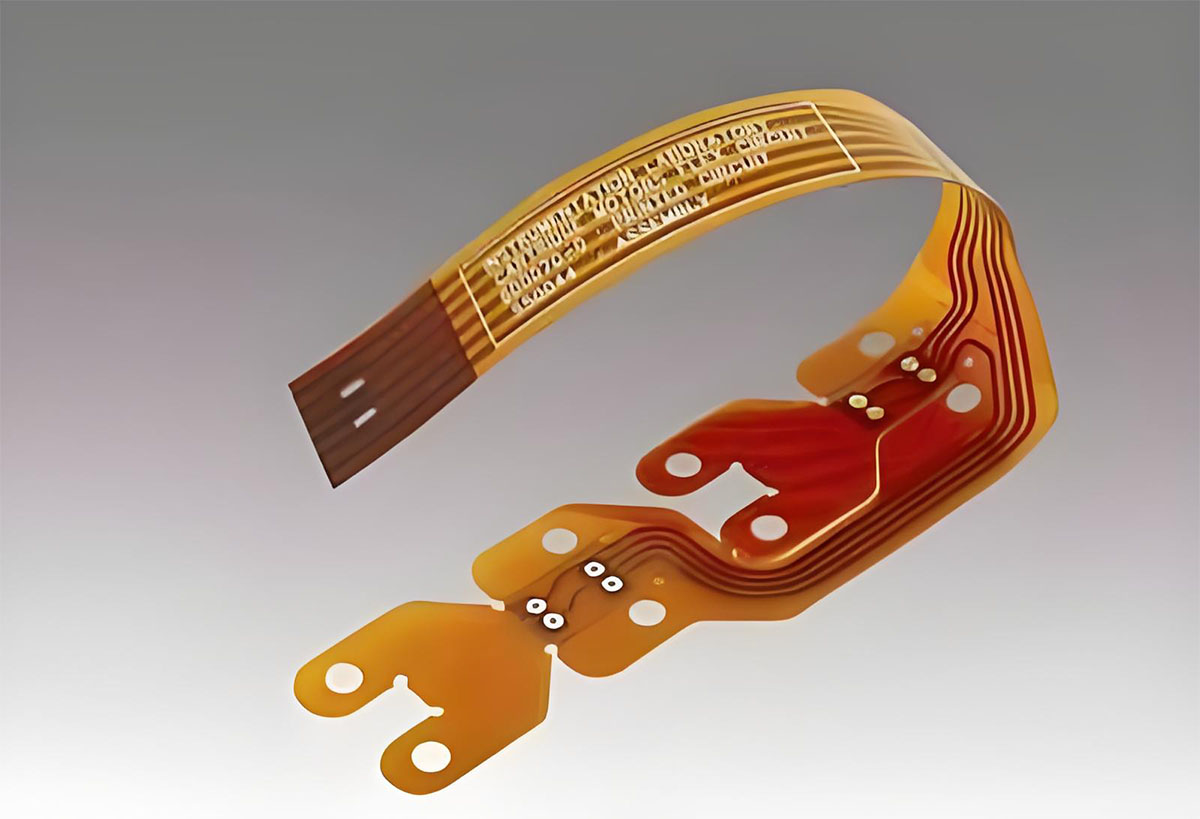

1. FPC flexible circuit boards are flexible

One of the most significant advantages of using FPC flexible circuit boards is their ability to route and connect in three-dimensional spaces easily. They can be bent or folded as needed, and as long as they are bent within the permissible radius, they can withstand thousands to tens of thousands of uses without damage.

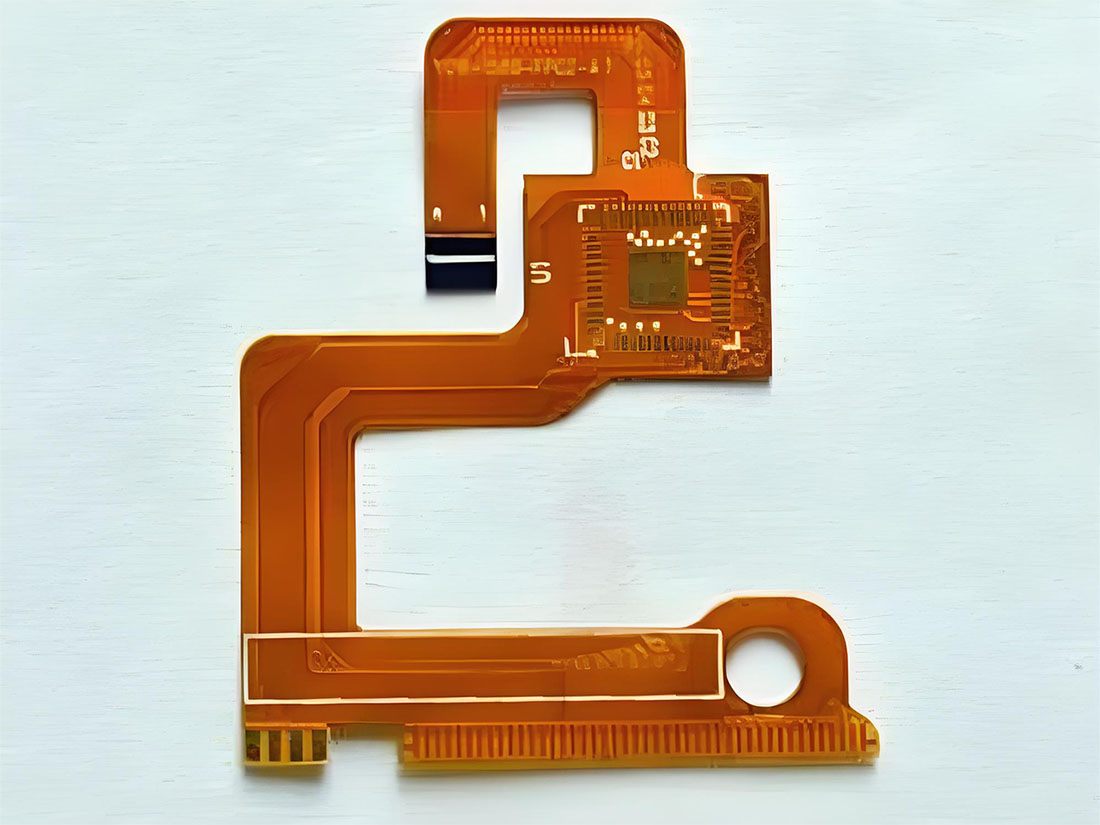

2. FPC flexible circuit boards are smaller

In component connections, compared to using wire cables, the conductor section of an FPC flexible circuit board is thinner and flatter, reducing the size of the wires. They can be shaped along the casing, making the device structure more compact and reasonable, thus reducing the overall assembly volume. Compared to rigid PCBs, space savings can be 60-90%.

3. FPC flexible circuit boards are lighter

Within the same volume, compared to wire cables, FPC flexible circuit boards are about 70% lighter under the same current-carrying capacity. Compared to rigid PCBs, the weight reduction is about 90%.

4. FPC flexible circuit board has the consistency of mounting

Using FPC flexible circuit boards eliminates the errors associated with wire cable connections. Once the design drawings are verified and approved, all subsequently produced flexible circuits are identical, preventing connection errors during assembly.

5. FPC flexible circuit boards are more reliable

When using FPC flexible circuit boards, routing can be done on the X, Y, and Z planes, reducing interconnections and increasing the overall system reliability. This also makes fault inspection easier.

6. The FPC flexible circuit board has the controllability of electrical parameter design

Designers can control capacitance, inductance, characteristic impedance, delay, and attenuation according to usage requirements when designing FPC flexible circuit boards. These parameters, related to conductor width, thickness, spacing, insulation layer thickness, dielectric constant, and loss tangent, can be designed to exhibit transmission line characteristics, which is difficult to achieve with wire cables.

7. FPC flexible circuit boards have monolithic solder ends

Like rigid PCBs, FPC flexible circuit boards have terminal pads that can eliminate the need for wire stripping and tinning, saving costs. Terminal pads can be connected to components, devices, and connectors using dip soldering or wave soldering, replacing manual soldering of each wire.

8. FPC flexible circuit board materials can be used

FPC flexible circuit boards can be made with different base materials depending on usage requirements. For low-cost applications, polyester film can be used, while for higher performance requirements, polyimide film is preferred.

9. FPC flexible circuit board low-cost

Using FPC flexible circuit boards can reduce overall costs due to:

– The consistency of various parameters of the conductors.

– Eliminating the errors and rework often occurring with cable wiring.

– Simplified structural design that can directly adhere to components, reducing clamps and fixtures.

– Lower cost for shielded wires using flexible PCBs.

10. Continuity of FPC flexible circuit board processing

As flexible foil-clad boards can be supplied continuously in rolls, continuous production of FPC flexible circuit boards is possible, helping to reduce costs.

二、Disadvantages of FPC Flexible Circuit Boards

1.FPC flexible circuit boards have high one-time initial cost

The initial cost is high due to the specialized design and manufacturing for specific applications, which includes expenses for circuit design, layout, and photomask production. Unless there is a specific need, it is generally not advisable to use FPC flexible circuit boards for small quantities.

2. It is difficult to change and repair FPC

Once manufactured, making changes to FPC flexible circuit boards requires starting from the original drawing or the programmed photoplotter, making modifications difficult. The surface is covered with a protective film that needs to be removed before repairs and restored afterward, a complex process.

3. Flexible circuit board FPC size is limited

FPC flexible circuit boards are usually manufactured using intermittent processes, limiting the production equipment size and preventing them from being made very long or wide.

4.FPC flexible circuit board is easily damaged by improper operation

Improper handling by assembly personnel can easily damage flexible circuits. Soldering and reworking require trained personnel to ensure proper handling and assembly.

Conclusion

In conclusion, FPC flexible circuit boards offer numerous advantages in terms of flexibility, size, weight, reliability, and cost-effectiveness, making them a valuable option for many applications. However, they also come with challenges such as high initial costs and difficulties in modifications and repairs. Understanding these pros and cons helps in making informed decisions about when to use FPC flexible circuit boards over traditional PCBs.

Leave A Comment