Rigid-Flex PCB and Flexible PCBs: Key Factors Influencing Costs

overview

When it comes to printed circuit boards (PCBs), you have the option to choose between rigid-flex and flexible PCBs. Although these two types differ in materials, design, and applications, one of the most decisive factors is their cost.

Factors Affecting Cost

Materials

For standard double-sided boards, materials commonly used include FR-4, CEM-3, etc. The board thickness can range from 0.6mm to 3.0mm, and the copper thickness varies from ½ Oz to 3 Oz. All of these factors contribute to significant price differences based on material choice. Additionally, solder mask inks, such as thermosetting ink and photosensitive green ink, also show price variations, leading to diverse costs based on material differences.

Production Process

Different production processes lead to different costs. For example, gold-plated boards and tin-sprayed boards, routing (milling) and punching for shaping, and the choice between screen-printed circuits and dry film circuits all affect the overall cost, contributing to price diversity.

Manufacturing Complexity

Even with identical materials and processes, the inherent complexity of the FPC flexible circuit board can result in varying costs. For instance, if two boards have 1,000 holes, but one has hole diameters greater than 0.6mm while the other has diameters smaller than 0.6mm, the drilling costs will differ. Similarly, if the line width and spacing differ, with one board having a width greater than 0.2mm and another smaller than 0.2mm, the production costs will vary. Higher complexity typically results in a higher scrap rate, leading to increased costs and price variation.

Customer Requirements

The stringency of customer requirements directly impacts the yield rate at the board factory. For example, a board that meets IPC-A-600E, class 1 standards might have a 98% pass rate, while meeting class 3 standards might only result in a 90% pass rate. This difference in yield affects the factory’s costs, ultimately leading to varying product prices.

Manufacturers

Even for the same product, costs can vary among manufacturers due to differences in process equipment and technical expertise. Some manufacturers prefer producing gold-plated boards because the process is simpler and cheaper, while others might see higher scrap rates with gold-plated boards, leading them to prefer producing tin-sprayed boards instead. Consequently, their pricing for tin-sprayed boards might be lower than for gold-plated ones.

Payment Methods

PCB manufacturers often adjust the price based on the payment method, with differences ranging from 5% to 10%. This adjustment also contributes to price variability.

Key Factors Influencing Rigid-Flex PCB Costs:

– Materials: The raw materials used in rigid-flex PCB manufacturing are often more expensive than traditional PCB materials. These boards utilize common materials like copper foil but also require non-flow prepreg, flexible copper-clad laminates, and thicker polyimide films.

– Assembly: The assembly process is more costly due to the need for separate components and complex steps.

– Manufacturing Yield: Producing rigid-flex boards requires specialized equipment and software tools, which can impact the final cost.

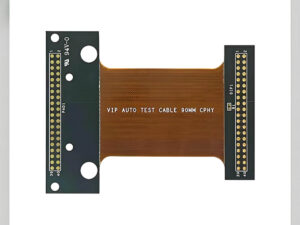

Flexible PCBs

Flexible PCBs use flexible base materials for circuit connections. These boards perform well across various industries and environments, from consumer electronics to medical systems and automotive applications. Regardless of where they are used, flexible PCBs simplify component assembly, support higher circuit densities, and reduce wiring errors.

Factors affecting the cost of flexible PCBS

Similar to rigid-flex boards, the cost of flexible PCBs is influenced by three primary factors:

1. Size: The most common pricing for flexible PCBs is based on a per-square-inch basis. Standard sizes are 12” x 24” and 18” x 24”. Larger sizes may incur additional costs.

2. Circuit Structure: Fewer circuits in the panel result in lower costs. If the circuit structure requires additional steps, such as folding or adding stiffeners, the price increases.

3. Volume: When ordering a small quantity of flexible PCBs, there might be an additional fee to cover overhead and engineering costs.

How to Reduce Costs

You can reduce the cost of rigid-flex PCB and flexible PCBs by reducing the number of layers, minimizing layer thickness, optimizing panel space, carefully selecting materials like laminates, and completing the design with precision.

Leave A Comment