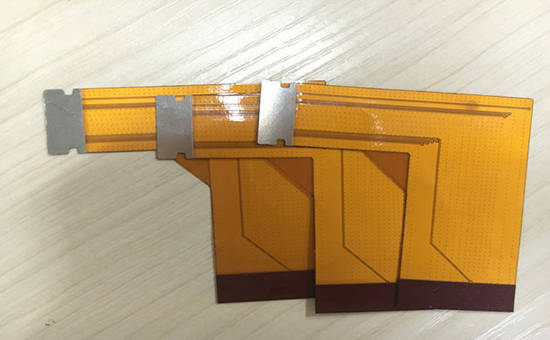

Intelligent Manufacturing of Double-Sided Flexible PCBs

Introduction

Double-sided flexible PCBs are revolutionizing the electronics industry with their two-layer substrate design. Unlike single-layer FPCs, double-sided FPCs offer greater design flexibility and more complex circuit layouts. This article covers the advantages of Double-sided flexible PCBs and explores smart manufacturing challenges and solutions.

Advantages of Double-Sided Flexible PCBs

High Integration and Lightweight Design

Double-sided FPCs allow for higher circuit density and integration within a limited space, making them ideal for compact and lightweight electronic devices. Utilizing both sides for circuit routing significantly enhances the functional density while maintaining the lightweight characteristics crucial for modern electronics.

Excellent Flexibility and Reliability

The flexible nature of the substrate used in double-sided FPCs provides outstanding bendability and reliability. This adaptability suits them for complex and dynamic product structures and operational environments. Even under frequent bending conditions, double-sided FPCs maintain superior electrical and mechanical performance.

Challenges in Smart Manufacturing for Double-Sided Flexible PCBs

Flexible APS Scheduling

Manufacturing double-sided flexible PCBs involves complex processes and long production cycles. Effective Advanced Planning and Scheduling (APS) systems are essential to manage production efficiently. Traditional manual scheduling is inefficient and cannot adapt to the rapid changes in production demands. Implementing an APS system based on constraint theory can optimize scheduling, balance capacity, and load, and ensure seamless operation across the production line.

System Integration

Essential tools such as DFM, EDA, and CAM must be seamlessly integrated to enhance data linkage and reduce errors. For example, systems like InPlan/InCam facilitate data transfer between planning, ERP, and production equipment, ensuring automated and accurate parameter downloads and minimizing manual errors.

Equipment Data Collection

The PCB manufacturing industry involves diverse equipment with varying degrees of automation. Collecting real-time production and inspection data is crucial for process optimization and quality traceability. This requires integrating sensors, PLCs, and control systems to handle the different protocols and data formats used by various equipment.

Orderly Transfer of Semi-Finished Products

The lengthy and large-scale production lines in PCB manufacturing necessitate efficient batch and serial number management for semi-finished products. Embedding QR codes in the design and using barcode scanners at key stages ensure accurate tracking and quality control.

Quality Data Traceability

Double-sided FPCs involve multiple online inspection stages, each generating significant data. This data must be cleaned, organized, and matched with batch and serial numbers for easy tracking and analysis. Implementing SPC reports based on this data helps optimize production processes and improve quality control.

Smart Manufacturing Solutions for Double-Sided Flexible PCBs

Automation of Equipment and Production Data

Automated systems should deliver precise production parameters to equipment and collect high-frequency data on the production process. Real-time data collection and automated reporting improve efficiency and ensure production quality.

Refined Traceability and Quality Control

Implementing comprehensive traceability for each production lot, down to individual panels or sets, is essential. Automated data collection and control at key stages provide real-time alerts and prevent quality issues, supporting detailed analysis and process optimization.

Visualization of Planning and Production Site

Smart manufacturing solutions should provide real-time visibility into production plans, equipment utilization rates, and order execution status. Dynamic simulations of equipment status, such as temperature and pressure, enhance operational transparency and decision-making.

Management of Developer, Copper Plating, and Gold Plating Formulas

Automated chemical dispensing systems based on real-time sensor data ensure the stability of production formulas, maintaining consistent quality throughout the manufacturing process.

Automated Tool Management

Digital management of tool usage, including tracking drill bit lifespan, usage quantity, and precision, enhances efficiency. Automated retrieval and return systems further streamline tool management processes.

Conclusion

Double-sided flexible PCBs offer significant advantages in integration, flexibility, and reliability. However, smart manufacturing presents unique challenges that require advanced scheduling, system integration, data collection, and quality control solutions. By addressing these challenges with innovative technologies, manufacturers can fully leverage the potential of double-sided FPCs, ensuring high-quality, efficient production processes.

Leave A Comment