PCB Testing: 8 Essential Methods for Quality Assurance (2025 Update)

Printed-circuit boards (PCBs) are essential for all electronic products. Manufacturers use them in smartphones, medical devices, computers, and military equipment. As PCBs become more complex with high densities, fine pitches, and multilayers, full test coverage is crucial. This helps protect against hidden defects and ensures steady manufacturing yields.

In today’s post, we will explore 8 common PCB testing methods. We will look at what they are, their common uses, and their pros and cons. We will also discuss why these methods are still important in PCB manufacturing. These techniques help check if your PCB performs well and meets design specifications.

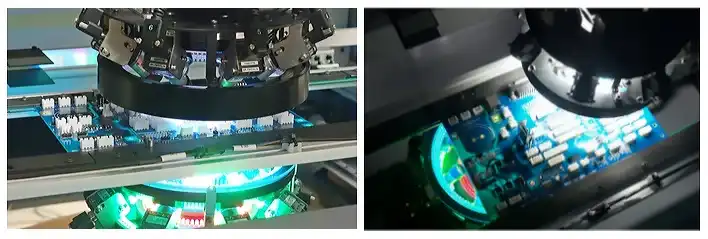

1. AOI (Automated Optical Inspection)

Taking top-and-bottom AOI. Images courtesy of MEK Marantz Electronics

AOI machines use high-resolution cameras to find surface-mounting errors. These errors include solder bridges, missing parts, and misalignment.

Scan after solder paste printing or reflow soldering in SMT assembly.

Advantage: Fast, non-contact, ideal for high-volume lines

Limitation: Cannot detect internal defects (e.g., via voids)

Reference:

Automated Optical Inspection (AOI), Apps, and Machine Learning: Tools for PCB Quality Control

2. In-Circuit Testing (ICT)

ICT involves electrical probes that test individual components on a PCB assembly for shorts, opens, and component values.

Best for: Mass production, especially in rigid or flex-rigid boards

Tools: Bed-of-nails fixture, test access via PTH holes

Limitation: Costly fixture setup for small-batch runs

Reference:

How In-Circuit Tests Ensure PCBA Quality and Reliability

3. Flying Probe Testing

Flying probes work like ICT but do not use a fixed test bed. They move across the board to check netlist connections and basic component values.

Advantage: Low setup cost, flexible for prototypes, and low-volume PCB assembly

Limitation: Slower than ICT; limited by access points

4. Boundary Scan (JTAG Testing)

For complex digital boards, boundary scan testing lets embedded parts test each other. You perform this through a serial test access port.

Application: BGA-heavy designs, high-density interconnect PCBs (HDI PCBs)

Advantage: Ideal for testing inaccessible areas

Limitation: Requires JTAG-compatible devices

Reference:

5. X-ray Inspection (AXI)

Automated X-ray Inspection checks for hidden defects beneath BGA packages and inside multilayer PCBs.

Detects: Cold solder joints, voids, internal misalignments

Used in: Medical, military, and aerospace boards

Limitation: Expensive equipment; typically post-reflow

6. Functional Testing (FCT)

FCT Test

Functional tests simulate real-world conditions to validate board performance under load.

Benefit: End-to-end validation of assembled PCB

Used for: Final test phase before shipment

Tools: Custom test jigs, software simulators

Reference:

Functional Circuit Test (FCT) – A Basic Introduction Is Here – NextPCB

7. Visual Inspection

Visual Inspection

While basic, manual inspection still plays a role, especially for prototype PCBs, double-sided boards, and connector zones.

Used in: Low-budget setups or quick QA checks

Tips: Combine with checklists or smart magnification tools

Reference:

The essentials of manual visual inspection in PCB manufacture

8. Environment & Burn-In Testing

Burn-in involves running a board under stress conditions (high temp/load) to screen for early failures.

Used in: Automotive, military, or mission-critical applications

Test types: Thermal cycling, humidity, vibration, high-voltage

Choosing the Right PCB Test Strategy

The right test combination depends on:

- Board type: rigid, flexible PCBs, rigid-flex PCBs

- Production volume: prototype vs. mass production

- Application risk: consumer vs. industrial/medical

- Layer complexity: single-sided, double-sided, or multilayer PCB

Integrating effective testing ensures fewer defects, lower returns, and a stronger reputation in the market.

Conclusion

Using the right testing strategy is important. This applies whether you are making flexible FPC boards, high-speed HDI circuits, or standard single-sided assemblies. This helps ensure your products perform consistently.

Need help designing or validating your PCB test flow? Gekun provides end-to-end PCB solutions, from design to SMT to testing. Get in touch with our engineering team today.

Leave A Comment