FPC Mobile for Slim & High-Performance Smartphones

Key Applications of Mobile FPCs

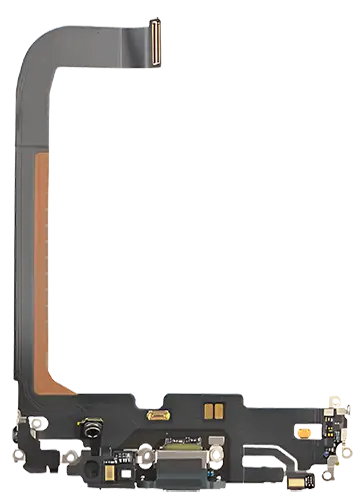

1. The Backbone of Connectivity

- Acts as a central wiring system, linking the motherboard to functional modules

- Facilitates high-speed data transmission for displays, speakers, and touchscreens

- Enhances durability, ensuring long-term performance in compact devices

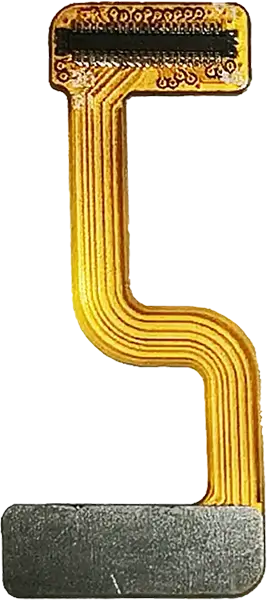

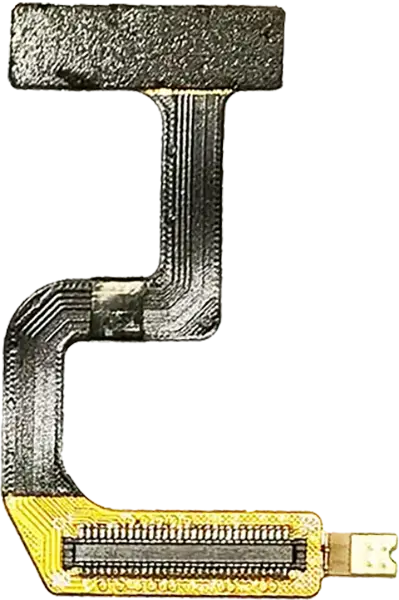

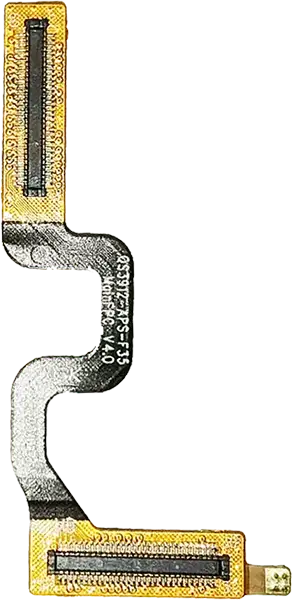

Four layers

Six layers

Eight layers

Flip Cellular Phone use

Double-sided

Four layers

Connect FPC for mobile phone

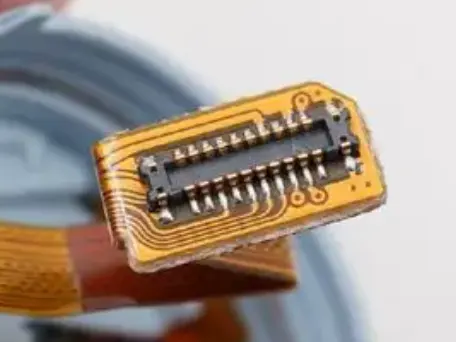

2. Mobile FPC Connectors: Ensuring Secure & Stable Connections

To ensure the stability and flexibility of the contact, FPC requires specialized connectors to achieve it. In current applications, there are mainly two types, which are:

- BTB (Board-to-Board) Connectors

Compact connectors link PCBs. They have high-density pins, like a 0.35mm pitch, and low-profile designs, with a height of 0.6mm or less. Great for small devices like smartphones. It offers stable connections but has a limited number of mating cycles.

- ZIF (Zero Insertion Force) Connectors

Designed for flexible circuits (FPC/FFC), this enables easy, tool-free insertion and removal. It also features a locking mechanism. Common in display cables, supports frequent maintenance but requires a larger space

3. Applications: Where Are They Used?

Perhaps you have a curious question: What are the uses of FPC in mobile phones?

They are widely used in:

- Smartphone displays – Enabling ultra-thin touchscreens

- Camera modules & fingerprint sensors – Supporting precise image and biometric data

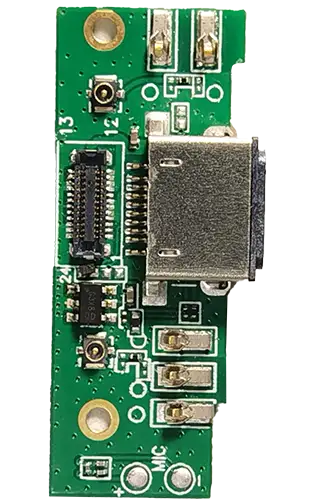

- Battery connectors – Ensuring stable power distribution

- Flexible wearables & foldable devices – Optimizing the use of space

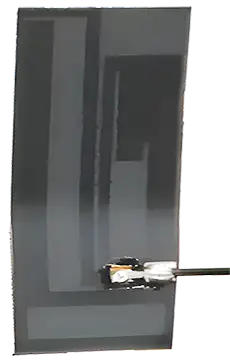

- Antenna Modules – Enhancing wireless communication for 5G, Wi-Fi, and Bluetooth

- Speaker and Microphone Modules – Supporting high-quality audio transmission

- Haptic Feedback Systems – Enabling advanced vibration feedback for immersive experiences

- Fast Charging Interfaces – Ensuring efficient power transfer and voltage regulation

Camera

LCD

Antenna

Side-Key

How Are Mobile FPCs Manufactured?

If Creating high-performance circuits, It must have large requirements of precision engineering. So I’m Here’s a simplified breakdown:

1. At Material Selection

- Polyimide (PI) for flexibility & heat resistance

- The electrical performance of copper foil is exceptional.

- Protective coating to prevent wear and corrosion

2. And Circuit Patterning & Etching

- Advanced laser cutting & chemical etching ensure precise, high-density circuits

- Multilayer stacking allows compact, high-performance designs

3. Other Component Assembly & Quality Testing

- BTB & ZIF connectors are integrated for stable connectivity

- Rigorous bending & heat resistance tests ensure durability

Why Choose Gekun?

Because We have over 10 years of experience, So our can provide:

- Custom mobile FPC designs for next-gen smartphones

- Precision engineering & EMI protection for reliable performance

- Flexible & durable circuits for compact electronic devices

Looking for high-quality FPC solutions for mobile devices?

Get A Quote