Unlocking the Future of Electronics: How Flexible PCB Buttons Are Changing Device Design

<

Summary:

Manufacturers create flexible PCB buttons from flexible printed circuit boards. They use very thin copper layers and high-quality dielectric materials. This design allows for slim, high-density PCBs in today’s compact electronic products.

By using advanced flex circuits instead of rigid circuit boards, manufacturers get better durability. This applies to products like remote controls and wearables. They also manage the costs of materials effectively. This guide explores their construction, benefits, design considerations, cost drivers, and future trends.

What Are Flexible PCB Buttons?

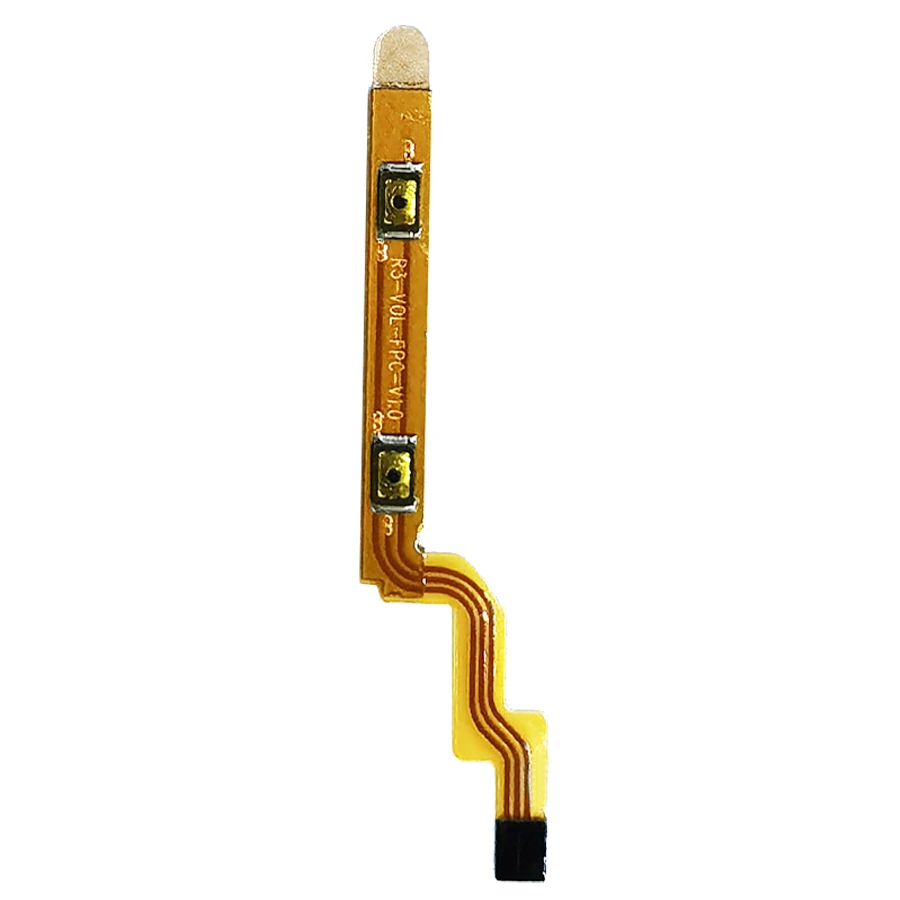

Flexible PCB buttons are switch interfaces made on bendable flex PCBs. They replace wire harnesses and rigid boards in tight spaces.

They consist of etched copper layer traces laminated onto polyimide or polyester dielectric layers, offering both tactile and capacitive actuation

Flex designs can bend repeatedly without breaking. This makes them perfect for side-mounted power and volume keys, as well as main control buttons.

Key Components & Materials

Copper Layer: Ultra‑thin copper foil (as low as 9 µm) delivers high conductivity in high-density layouts

Dielectric Materials: Polyimide and polyester substrates provide electrical insulation and flex endurance. Multi‑layer stacks balance signal integrity and flexibility

Dielectric Layers: Thin dielectric films between copper traces prevent crosstalk and maintain performance in compact button arrays

Expensive Materials: While polyimide and fine‑pitch copper raise material costs, they enable miniaturization and reliability that rigid boards cannot match

Design & PCB Layout Considerations

When integrating flex circuits into PCB design, engineers must:

Optimize Trace Routing: Use high-density interconnect (HDI) methods to place micro-vias and narrow traces. This maximizes routing in small button areas

Layer Selection

- You can choose a single-layer flex for simple switch matrices.

- Alternatively, you can select multi-layer structures for complex button arrays and sensor integration

Rigid‑Flex Transitions: Incorporate stiffeners or rigidized zones to anchor the button area, balancing flexibility with mechanical support

Material Stack‑up: Select dielectric thickness and copper weight to achieve target impedance, signal integrity, and tactile response

Applications in Electronic Products

Flexible PCB buttons appear across diverse devices:

Remote Controls: Slim handheld units leverage flex circuits for multi‑button layouts, reducing assembly complexity

Wearable Electronics: Smartwatches and fitness bands use flex PCBs to fit buttons within curved housings without bulky wiring

Automotive Controls: Dashboard and steering‑wheel buttons demand durability under temperature extremes—flex designs meet these harsh environmental requirements

Advantages Over Rigid Circuit Boards

Cost Optimization

The initial material costs are higher. However, savings from assembly and fewer errors can lower total ownership costs. This reduction can be up to 70% compared to wire harnesses

Key Features of Flexible PCB for Buttons

- Ultra-Thin and Lightweight

Flexible PCBs are designed to be super-thin, with a thickness of less than 0.1mm. This is why they work well for ultra-thin devices like smartphones, tablets, and wearables, where space and weight matter.

- Flexibility and Durability

With these PCBs, devices with frequent button usage will receive consistent performance even after repeated bending and dynamic movements. They are especially suitable for foldable devices or gadgets with complex mechanical layouts. - Stable Signal Transmission

Flexible PCBs help send signals from a power button or a main keypad. They ensure low signal loss and quick response times. This guarantees smooth functionality across all button types. - Customizable Designs

Flexible PCBs can be customized to fit various button configurations, including single-layer and multi-layer designs. Manufacturers can tailor the PCB layout to meet specific product requirements, ensuring optimal performance and integration.

Leave A Comment