What is flexible circuit board (FPC)?

A flexible circuit board of bent and folded cool flexible substrate material is a circuit board type for application of flexibility or limited space.

When we say flexible circuit board vs rigid circuit board, what defines the difference?

Flexible Circuit

Rigid Circuit

Flexible circuit boards are used in many electronics, medical devices, automotive, aerospace, and other industries, particularly when applications have high flexibility and space limitations.

How flexible circuit boards are manufactured?

The Process of Manufacturing Flexible Circuit boardsThe manufacturing process of flexible circuits primarily involves preparing the substrate, followed by designing the graphics, etching, drilling, plating, laminating copper, and finally assembling.

Benefits of Flexible Circuit Boards

Take a look at the advantages of flexible circuit boards, they include excellent flexibility, thinness, lightweight, bendability, foldability, complex shapes and limited space applications.

What are the disadvantages of flexible circuit boards?

Higher manufacturing costs, low durability, and exceedingly low thermal conductivity.

These problems can happen with any kind of circuit board, so how do we verify flexible circuit board reliability?

Flexible circuit boards are made to be reliable, controlled manufacturing processes, dependable soldering and interconnection methods, and strict inspection and testing protocols guarantee their reliability.

What is the suitable materials for flexible circuit board?

Choosing appropriate materials for flexible circuit boards requires analyzing application requirements, environmental conditions, temperature ranges, reliability requirements, and selected substrate material, copper layer thickness, and lamination structure.

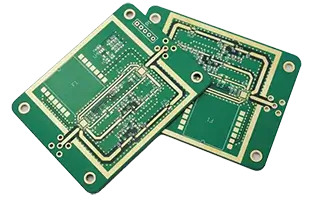

PCB manufacturing: What is the process of manufacturing PCBs?

From designing and laying out the graphics and then to transferring, etching, drilling, plating, and assembling the components of printed circuit boards (PCBs)

How do you design printed circuit boards?

In printed circuit boards, design specifications ensure the correct dimensions, routing rules, spacing, layer structure and material selection to ensure the functionality, manufacturability, and reliability of the circuit board. Signal integrity, thermal management, and electromagnetic compatibility must also be taken into account.