How FPC Fingerprint Sensors Work: 5 Expert Tips

Introduction: The Evolution of FPC Fingerprint Sensors

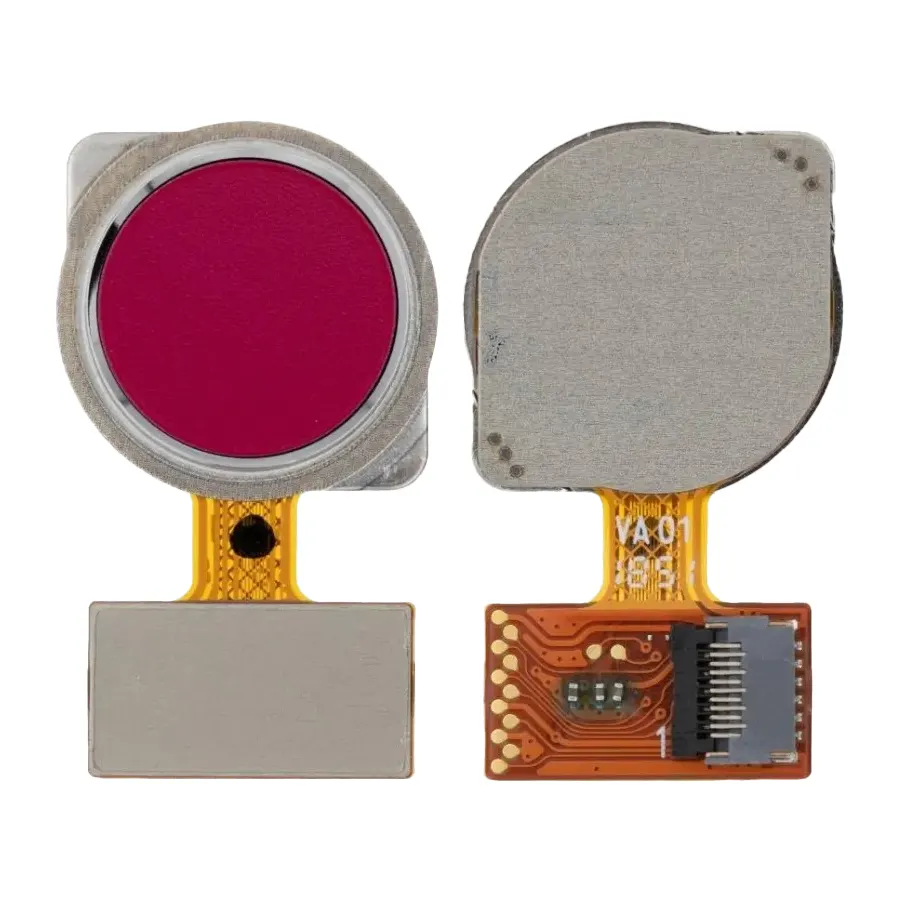

Fingerprint recognition has improved a lot. It has changed from early capacitive sensors to today’s thin and high-performance biometric modules. Among all fingerprint recognition technologies, FPC (Fingerprint Cards) sensors are notable. People recognize them for their accuracy, easy integration, and advanced signal processing.

This guide explains how FPC fingerprint sensors work. It also helps you choose the right one for your needs. You will find five expert tips to improve their performance. Plus, there is a look at what is coming next in biometric authentication technology.

How FPC Fingerprint Sensors Work

FPC sensors primarily use reflection-based capacitive sensing, known as Echo Sensing. Unlike traditional capacitive sensors that measure the finger’s contact, Echo Sensing sends out a signal. This signal reflects off surfaces, allowing the sensor to “see through” materials like 300μm glass. This makes it ideal for under-display use or tough environments.

Key Advantages of Echo Sensing:

- Penetrates up to 300μm of hardened glass (vs <50μm in traditional sensors)

- Withstands -40°C to +85°C environments

- Enhanced ESD resistance: up to ±30kV

- Improved performance on dry, wet, or oily fingers

5 Expert Tips

Tip 1: Match Sensor Type to Your Use Case

Choosing the right FPC sensor model for your application can significantly improve performance and reduce costs. Below is a comparative summary of the top models:

| Model | Ideal Application | Thickness | Interface | Key Features |

|---|---|---|---|---|

| FPC1020 | Smart locks, POS | 1.1 mm | SPI | 30kV ESD, cost-effective |

| FPC1268 | Smartphones, foldable devices | 0.7 mm | SPI/UART | OLED-compatible, glass-through sensing |

| BM-LITE | Automotive, BMS | 1.4 mm | UART | Waterproof (IPx7), industrial-grade -40°C~85°C |

Pro Tip: Match the sensor thickness and interface type with your product’s design early in development.

Tip 2: Optimize Sensor-to-Controller Communication

FPC sensors commonly use SPI or UART interfaces. Selecting and configuring the right protocol can prevent latency issues or data corruption.

- SPI: Recommended for fast response applications. Use a clock frequency of 10MHz for sub-0.3s read time.

- UART: When using soft serial, limit baud rate to ≤9600bps to avoid data loss or misalignment.

Avoid this trap: Make sure your firmware manages flow control well in noisy environments. This is important for embedded Linux or RTOS platforms.

Tip 3: Design with EMI and ESD Immunity in Mind

Flexible circuit boards (FPCs) introduce new EMC challenges. To ensure robust performance:

- Double-layer copper shielding: Apply 1oz copper foil on both sides of the flex layer.

- Star-grounding topology: Keep grounding impedance <10mΩ to reduce noise loop interference.

- Substrate choice: Use high-performance PI films like Sumitomo for triple bend-cycle durability.

Note: These design measures improve noise immunity by up to 30dB, ensuring reliable operation even in high-RF environments.

Tip 4: Implement Advanced Fingerprint Algorithms

FPC’s sensor modules support next-gen features beyond static matching:

- EvoTouch™ Dynamic Calibration: Automatically updates templates every 24 hours to adapt to finger surface changes (peeling, oils, etc.).

- RF Liveness Detection: Sends out a 13.56MHz signal to go through the skin. This checks if the skin is real and stops fake silicone from tricking the system.

Security Boost: FAR (False Acceptance Rate) can be improved to 1 in 500,000 with adaptive AI-based modeling.

Tip 5: Run Rigorous Production Testing

Mass production introduces new variables that can compromise performance. Keep the following in check:

- Protective film thickness: Use laser profilometry to ensure ±5μm tolerance.

- Aging simulation: Perform 85°C/85%RH stress tests for 1000 hours to validate sensor signal stability.

- High-speed routing rules: Maintain spacing ≥3×trace width between power and signal traces to reduce crosstalk.

Bonus: What’s Next in FPC Fingerprint Tech?

1. OLED Integration Without Polarizers

FPC’s new ultra-thin sensor is just 0.3mm thick. You can place it directly into OLED displays. This boosts light transmittance by 40%. It is perfect for foldable phones and phones without bezels.

2. Automotive Integration

FPC sensors are now replacing traditional harnesses in Tesla’s BMS systems, improving accuracy to ±0.5mV. In-vehicle payment and identity modules are also emerging.

3. Post-Quantum Security

FPC is experimenting with quantum-encrypted fingerprint templates based on NIST’s post-quantum cryptography protocols. This will dramatically enhance resistance to brute-force attacks.

Conclusion: Build Smarter Biometric Systems

FPC fingerprint sensors deliver unmatched precision, flexible integration, and future-ready biometric capabilities. Whether you’re designing smart consumer products or industrial control systems, optimizing sensor selection, layout, and testing can unlock new levels of security and reliability.

Looking to integrate an FPC fingerprint solution into your next project? Gekun’s expert engineering support and advanced FPC manufacturing can help you get to market faster, with confidence.

Learn about others

What is the Sensor? https://en.wikipedia.org/wiki/Sensor

What is the Image sensor?: https://en.wikipedia.org/wiki/Image_sensor

Leave A Comment