Multilayer Flex PCB

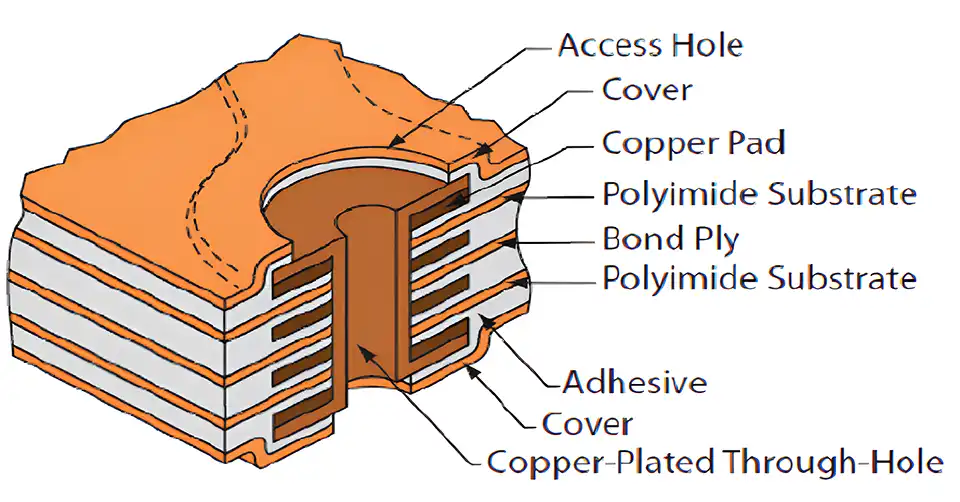

Multilayer FPCs are designed for use in space-saving, high-performance electronic products. These flexible circuits have three or more conductive layers. Each layer is bonded with flexible dielectric layers, such as polyimide or LCP. Unlike the rigid boards, they are dynamically flexible and can be bent to support the 3D routing in a small space.

We at Gekun offer high-reliability and mission-critical electronics-grade multilayer flex circuits produced with advanced lamination and ultra-precision alignment methods.

Read on to learn more about Multilayer Flex PCBs.

Structure diagram

When to Choose a Multilayer Flex PCB

Choosing a multilayer flexible circuit makes sense when your design requires:

- High circuit density in a limited space

- Multiple signal and ground planes for EMI shielding or impedance control

- Reduced connector use, lowering weight, and improving reliability

- Controlled impedance for high-speed data transmission (USB, HDMI, LVDS, etc.)

- Enhanced routing flexibility in rigid-flex designs

High-frequency signal performance and density packing are important in devices like medical imaging, aerospace control systems, consumer electronics, and wearables for IoT. Engineers often choose multilayer flex PCBs for these applications. They are also popular for automotive electronics, in which space and shock resistance are very important.

But if your application calls for layer-to-layer via connections, power-ground separation, or high reliability interconnects, a multilayer flex is the solution.

Types of Multilayer Flex PCB

Multilayer flexible PCBs are classified based on structure and intended function:

Standard Multilayer Flex Circuits

Used in devices requiring high-density routing and minimal mechanical movement. Ideal for stacked assemblies or folded sub-systems.

Multilayer Rigid-Flex PCBs

Combine rigid boards with flex layers to support component mounting and flexible interconnect. Used in medical wearables, folding electronics, and defense systems.

HDI Multilayer Flex PCBs

Feature microvias and blind/buried vias for ultra-compact routing. Essential for smartphones, tablets, and miniaturized sensors.

Dynamic Flex Circuits with Multiple Layers

Designed for continuous motion, such as robotic arms, foldable displays, or camera modules. Built with rolled annealed copper for high flex life.

You can customize each type based on the flex PCB stack-up design. This includes signal integrity needs and specific mechanical constraints for your application.

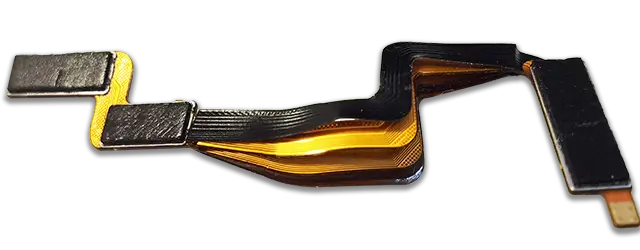

Standard Multilayer Flex Circuits

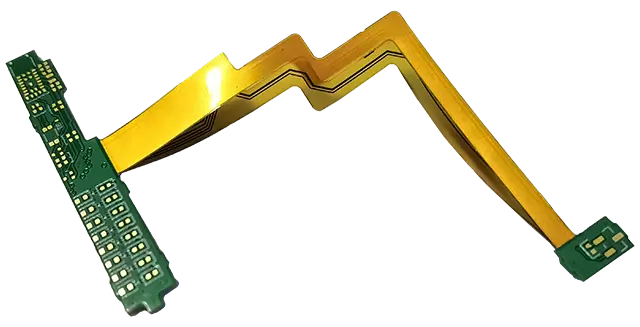

Dynamic Flex Circuits with Multiple Layers

Rigid-Flex Multilayer PCB

Advantages of Multilayer Flexible Circuits

Multilayer Flex PCBs Have Another Layer Of Benefits To Gain That May Greatly Exceed One Or Two Layered Circuits:

- High-Density Interconnect (HDI): Multilayer stacking supports dense component layouts and short trace lengths for faster signal transmission.

- Impedance Control: Ideal for high-speed flex circuits that require signal integrity in data-sensitive applications.

- Compact & Lightweight: Eliminate bulky wiring harnesses in medical devices, military equipment, and wearable electronics.

- Thermal Management: Distributes heat more evenly across layers, reducing hotspots in high-current designs.

In conclusion, choosing us for your custom Multilayer Flex PCB needs is the best decision!

Applications of Multilayer Flexible PCBs

Multilayer flexible circuit boards are widely used in:

Medical Devices: Such as wearable heart monitors and diagnostic probes requiring high flexibility and hygiene.

Automotive Electronics: Used in ADAS, infotainment systems, and engine control modules where space and heat resistance are key.

Aerospace & Defense: Deployed in satellite systems and avionics requiring lightweight, high-reliability interconnects.

Consumer Electronics: Smartphones, cameras, and foldable devices benefit from bendable PCBs in compact enclosures.

Our custom multilayer flex PCB solutions can be tailored to meet your product’s technical and environmental demands.

Design Considerations for Multilayer Flex PCB

Designing a multilayer flex circuit requires careful consideration of mechanical and electrical factors:

Bending Radius: To avoid cracking during dynamic movement, each layer’s bend radius must be properly calculated.

Stack-up Optimization: Choosing the right layer arrangement ensures signal integrity and EMI control.

Coverlay vs. Solder Mask: Coverlays provide better mechanical protection in flexible areas, particularly for dynamic flex zones.

Controlled Impedance: For USB, HDMI, and RF lines, impedance-controlled traces ensure data accuracy.

Gekun offers flex circuit design guidelines to help customers select the best materials and layer stack-ups for their specific applications.

Multilayer Flex PCB Manufacturing Process

Our flexible PCB manufacturing process ensures quality from prototype to volume:

Material Selection: We use high-grade polyimide or LCP films with rolled annealed copper for improved flexibility.

Layer Lamination: Each conductive layer is bonded using controlled heat and pressure, ensuring precise alignment.

Drilling & Plating: Through-holes and vias are drilled using laser or mechanical techniques, then plated for reliable interconnects.

Etching & Imaging: Circuit patterns are transferred and etched with tight tolerances.

Coverlay Application: A polyimide film and adhesive are added to protect traces and pads.

Electrical Testing: 100% netlist testing verifies conductivity and circuit continuity.

Why Choose Gekun for Your Multilayer Flex PCB?

Gekun is a reliable manufacturer of multilayer flex PCBs. They have a lot of experience in HDI flex circuits, impedance-controlled designs, and flex-rigid combinations. Our capabilities include:

- High-layer count circuits up to 10 layers

- Quick-turn prototyping & low-volume runs

- Flexible PCB assembly services

- Design support for high-frequency and high-current applications

We provide precision and performance for all flexible boards. This includes next-gen wearable electronics, medical devices, and automotive systems.

We support rapid flex PCB prototyping as well as high-volume production runs, all backed by rigorous quality control.

Frequently Asked Questions

Q1: How many layers can a multilayer flex PCB have?

A: Most designs have 3 to 6 layers. Some advanced designs can have 8 to 10 layers. This depends on thickness and flexibility.

Q2: What is the typical thickness of a multilayer flexible PCB?

A: They can be ordered with thicknesses from 0.2mm to 1.2mm, depending on copper weight, dielectric, and coverlay used.

Q3: Can multilayer flex PCBs be used in dynamic applications?

A: Yes. When designed with the right bend radius and materials, they can handle repeated flexing. This is important for wearable and robotics products.

Q4: Do you offer rigid-flex combinations?

A: Absolutely. Gekun provides rigid-flex PCB manufacturing for designs requiring both stability and flexibility.

Get A Quote

[fusion_form form_post_id=”5445″ hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” /]