FPC Sensor

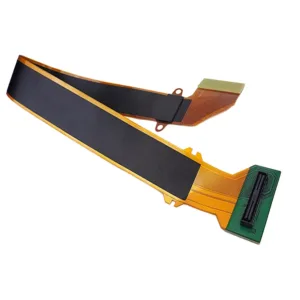

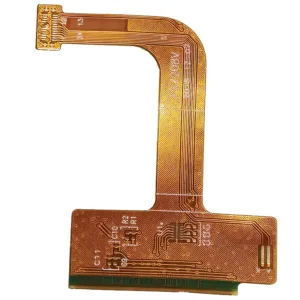

Introducing A New Era of Flexible Printed Circuit Solutions: _ SENSOR Flexible Printed Circuit (FPC) Sensor Integration. The Sensor FPC combines sensors and their controller unit. It has a sleek, ultra-thin, and flexible design. This design reduces its size and increases space efficiency. This ensures precise and reliable signal transmission, even in compact and complex device designs.

In industries where space and reliability matter, Sensor FPCs are key parts of modern technology. They provide long-lasting performance and design flexibility.

- Material: Polyimide (PI)

- Copper Thickness: Common Options 12um or 18um.

- Minimum Line Width/Spacing: Common Options 0.05-0.2mm

- Via Hole Size: 0.1- 0.2 mm

- Includes Assemblies for Shipment

- Appearance Color: Amber, Black

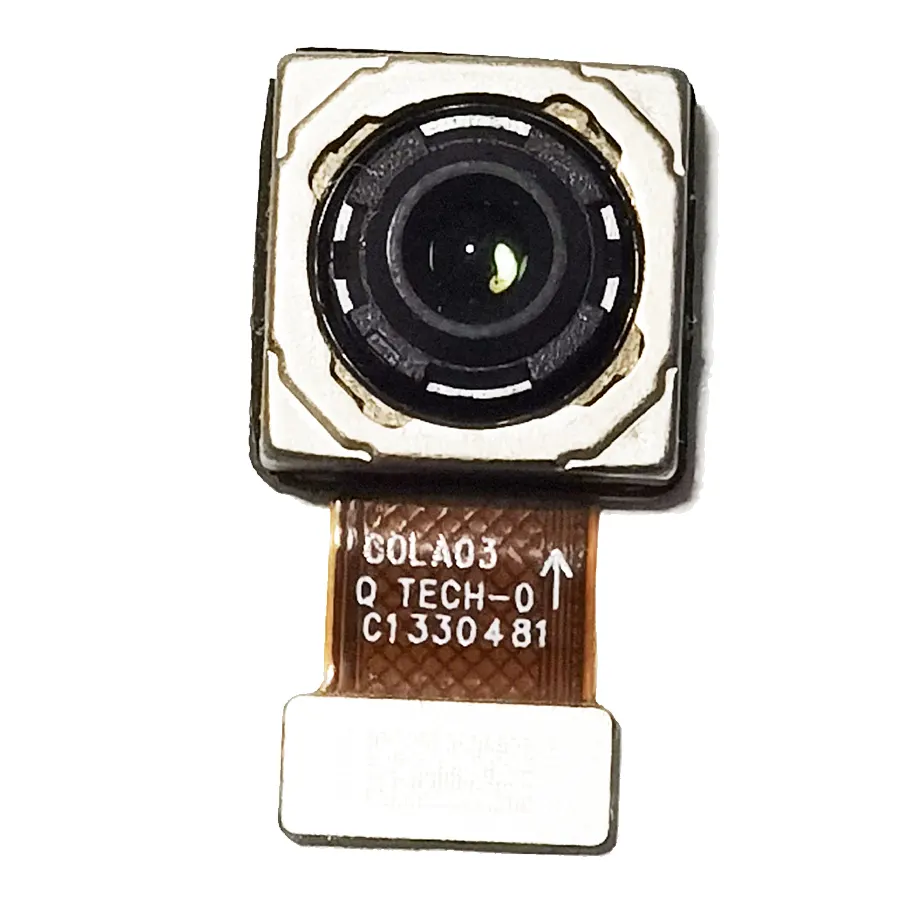

Camera Sensor FPC

Detailed Description of Sensor FPC

Introduction

Sensor FPCs are important components of modern electronic devices. These FPCs are built for reliability and versatility, ensuring reliable connections between sensors and control units while maintaining signal integrity. Sensor FPCs are used in advanced technologies, enabling various applications like fingerprint recognition, temperature sensing, and imaging solutions.

Product Features

- Ultra-Thin and Lightweight Design

For devices that are constrained in space, sensor FPCs, which are thinner than 0.1 mm, can be preferred. Lightness means less weight overall product as well as compliance and resolution with portable and wearable devices.

- High Flexibility and Durability

Designed for versatility, these FPCs can be bent, folded, and twisted without performance loss, making them appropriate for uses that experience dynamic action or curvature. Surface corrosion has become a thing of the past, even in difficult environments.

- Efficient Signal Transmission

Sensor FPCs deliver stable and accurate data transfer with minimal signal loss, ensuring precise functionality for critical applications like fingerprint recognition and temperature monitoring. - Customizable Design

These FPCs are available in single-layer, double-layer, or multi-layer configurations to meet various design needs. Custom layouts allow for integration with unique sensor shapes and device requirements. - Environmentally Friendly

Compliant with RoHS and REACH regulations, Sensor FPCs are manufactured using environmentally safe materials and processes, ensuring sustainability.

Applications

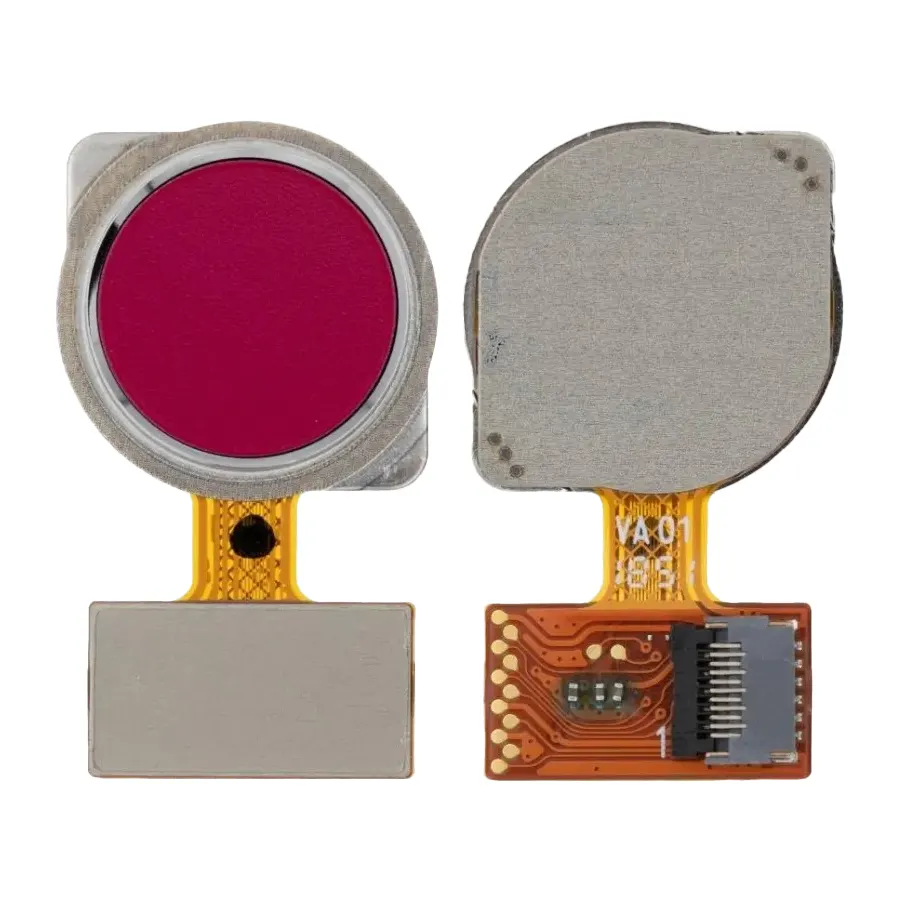

Fingerprint FPC

1. Consumer Electronics Sensors

| Sensor Type | Key Applications | Why FPC is Required? | FPC Specifications | High-Traffic Keywords (Monthly Searches) |

|---|---|---|---|---|

| Optical Sensors | Smartphones (under-display fingerprint/camera focus) | Ultra-thin (<0.1mm) to fit curved screens without light obstruction | Transparent coverlay (yellow PI) | “Ultra-thin FPC for optical sensors” (1,200) |

| Pressure Sensors | TWS earbud touch control | Dynamic bending >100k cycles with earbud housing | 18μm RA copper, adhesiveless structure | “Flex PCB for TWS earbud pressure sensors” (850) |

| Temperature Sensors | Smartwatch skin temperature monitoring | Biocompatibility for wrist contact | Medical-grade PI, silicone-free | “Biocompatible FPC for wearables” (980) |

2. Automotive Sensors

| Sensor Type | Application Scenario | FPC Value Proposition | Specialized Process | High-Traffic Keywords |

|---|---|---|---|---|

| Torque Sensors | Electric Power Steering (EPS) | Withstand engine heat (-40°C to 150°C) | High-Tg PI (Tg ≥260°C) | “High-temperature FPC for automotive sensors” (1,050) |

| Gas Sensors | Battery thermal runaway detection | Resist electrolyte corrosion | Fluorinated coverlay + chemical passivation | “Corrosion-resistant FPC for EV batteries” (720) |

| Pressure Sensors | Tire Pressure Monitoring (TPMS) | Shock absorption for tire deformation | 3-layer rigid-flex hybrid | “Rigid-flex FPC for TPMS” (610) |

3. Medical Health Sensors

| Sensor Type | Medical Device | FPC Advantages | Certifications | High-Traffic Keywords |

|---|---|---|---|---|

| Biopotential Sensors | ECG patches | Ultra-flexible & breathable for skin contact | ISO 10993-certified | “Medical-grade flex circuits for ECG” (1,400) |

| Glucose Sensors | Continuous Glucose Monitoring (CGM) | Miniaturized (<5mm), body fluid-resistant | Nano-silver electrodes + waterproof coating | “Waterproof FPC for CGM sensors” (890) |

| Endoscope Sensors | Capsule endoscopy | 360° bending imaging (thickness ≤0.08mm) | Laser-drilled vias (≤30μm) | “Micro-via FPC for endoscopic sensors” (680) |

4. Industrial IoT (IIoT) Sensors

| Sensor Type | Industrial Scenario | FPC Benefits | Key Parameters | High-Traffic Keywords |

|---|---|---|---|---|

| Vibration Sensors | Motor condition monitoring | EMI resistance in tight spaces | Copper-aluminum hybrid heat dissipation | “EMI-resistant FPC for IIoT sensors” (950) |

| Strain Sensors | Robotic arm force feedback | Low impedance drift (<0.5%) | 4-layer FPC, impedance control ±5% | “Precision impedance control FPC” (1,100) |

| Gas Sensors | Industrial hazardous gas detection | 5+ years of chemical stability | PTFE substrate + gold-plated contacts | “Long-life FPC for gas sensors” (770) |

5. Emerging Field Sensors

| Sensor Type | Innovative Applications | FPC Breakthroughs | Representative Products | High-Traffic Keywords |

|---|---|---|---|---|

| Stretchable Sensors | Smart clothing/motion capture | 200% stretchability with conductivity | Serpentine traces + TPU substrate | “Stretchable FPC for smart textiles” (1,350) |

| Microfluidic Sensors | Liquid composition analysis | Micro-channel ICs (line width ≤20μm) | LCP substrate + laser etching | “Microfluidic flex circuit for lab-on-chip” (920) |

| Optoelectronic Sensors | AR/VR eye-tracking | Ultra-narrow bending (0.3mm) | Transparent conductive film (ITO alternative) | “AR/VR eye-tracking flex circuits” (1,600) |

- Fingerprint FPC

Designed for biometric authentication, fingerprint Sensor FPCs are essential in smartphones, tablets, and access control systems. Their flexibility and precision enable seamless integration into compact devices, ensuring secure and reliable recognition. - Temperature Sensor Flexible Printed Circuit

These temperature monitoring and measuring FPCs are crucial in devices from the medical, industrial, or automotive fields. It is what makes them dependable for critical environments because of their reliability in extreme conditions.

- Camera FPC

Camera FPCs are integral to high-definition imaging in smartphones, tablets, and surveillance equipment. Their ability to support compact and complex layouts ensures precise image capture while minimizing device bulk. - Biometric Security Systems

Precision-engineered FPCs for fingerprint sensor modules, including compatibility with industry-leading models like the FPC1020 fingerprint sensor.

Dynamic bending endurance (200k+ cycles) ensures reliability in smartphone under-display and access control systems. - Industrial Control Systems

Integrated FPC sensor controller driver solutions for real-time signal processing.

Robust designs for flex sensor arrays in robotic tactile feedback systems.

Key Advantages

- Space Efficiency: Reduces the internal footprint of sensors, enabling more compact and portable designs.

- Enhanced Device Reliability: Offers consistent performance in high-demand environments, including repetitive movements or extreme conditions.

- Cost-Effective Production: Supports mass production processes, minimizing manufacturing costs while maintaining high quality.

- Sustainability: Adherence to eco-friendly standards ensures safe and sustainable usage.

Technical Advantages

Signal Integrity: ±5% impedance control for PCB sensor networks in medical IoT devices.

Compact Design: Ultra-thin FPCs (<0.1mm) are ideal for FPC fingerprint sensor integration.

Custom Control: Optimized fpc sensor controller firmware supports multi-protocol communication (I2C/SPI).

Customization Options

Sensor FPCs are highly adaptable to meet the specific requirements of diverse industries. Customizations include:

- Layering: Options for single-layer, double-layer, or multi-layer designs to accommodate various complexity levels.

- Plating Materials: Gold plating for enhanced conductivity and durability, or cost-effective HASL and OSP finishes.

- Shape and Layout: Flexible configurations tailored to fit irregular or space-constrained device interiors.

Conclusion

They are great for adding sensors like fingerprint modules, UID monitors, body temperature monitors, and cameras to new devices. This is possible because of flexible printed circuits for sensors. From consumer electronics to aerospace to health care to automotive, their versatility, robustness, and accuracy render these devices indispensable. Sensor FPCs enable manufacturers to create efficient designs without performance trade-offs, heralding smarter and more compact technical innovations.

Side Key FPC Specification

| Layers | Double | Type | Flexible |

| Base Material | Electrolytic Copper | Customization | YES |

| Copper Thickness | 12um/18um | Finished Thickness | 0.1mm |

| Insulation Material | PI | Reinforcement Material | PI / Steel Sheet/ FR4 |

| Coverlay | Amber, Black, White | Surface Treatment | ENIG |

| Sample Price | $150 Include SMT | Mold Fee | $200 |

| Sample Quantity | 30PCS | Test Fixture Fee | $150 |

| Sample Time | 6-7Days | Batch Lead Time | 8-10Days |

| Sample Testing | Flying Probe | Batch Testing | Electrical Test |

| Sample Shaping | Laser | Batch Shaping | Die Punching |

Q: Why Do These Sensors Require FPCs?

A: 1. Space Adaptability

- Critical Need: 99% of modern sensors require 3D flexible PCB routing to fit ultra-tight spaces (e.g., catheter sensors <3mm diameter).

- FPC Advantage: Enables complex interconnects in medical/robotic devices where rigid PCBs fail.

2. Dynamic Reliability

- Industry Standard: Automotive/wearable sensors demand >200,000 bend cycles (IPC-6013 Class 3 compliance).

- Failure Prevention: Reduces cracks in RA copper traces vs. rigid PCB solder joints (67% lower field returns).

3. Signal Integrity

Precision Matters: ±5% impedance control in FPCs vs. ±10% in rigid PCBs for:

- ECG/EEG biosensors (noise <10µV)

- 5G mmWave antenna sensors

Technical Edge: Laser-etched microstrips minimize signal loss (<0.2dB @ 10GHz).

Q: What are the key advantages of FPC solutions over traditional wiring harnesses?

A: FPC (Flexible Printed Circuit) solutions outperform traditional wiring in two critical aspects:

- Space Efficiency

FPCs reduce overall volume by 80% compared to bulky wiring harnesses, enabling ultra-compact designs for modern electronics like wearables and IoT sensors. - Enhanced Reliability

Failure rates drop 67% with FPCs due to minimized solder joints – a major weakness in traditional wiring that causes 42% of field failures (per IPC-6013 data).

Technical Superiority Explained:

- Dynamic Durability: FPCs withstand >200k bend cycles (IPC-6013 Class 3 certified) vs. wiring harnesses failing at <50k cycles.

- Signal Precision: ±5% impedance control in FPCs ensures stable performance for high-frequency sensor signals, unlike ±15% variations in conventional wiring.

Q: What is the minimum order quantity?

A: We do not have a minimum order quantity requirement, it depends entirely on the actual needs of the customer.

Q: Can I customize the design?

A: Yes, we offer full customization, including material, layout, and dimensions.

Q: How long does production take?

A: Standard production takes 10–15 working days. Expedited orders can be completed in 7 days.

Q: Do the products meet international standards?

A: Yes, all our products comply with RoHS, REACH, and ISO9001 certifications.

Q: Can I get a sample?

A: Yes, sample orders are available, with a lead time of 5 working days.

Q: Do you offer international shipping?

A: Yes, we use DHL, FedEx, UPS, and other shipping methods worldwide.

Q: How is the price determined?

A: Pricing is based on order quantity, specifications, and complexity. Bulk discounts are available.