Strengths of Visual Communication

Pioneering Visual Communication, Making Communication So Simple. This is Our Unique Strength.

Clearly Presenting Needs

We translate your requirements into realistic renderings, allowing you to visualize the final product and ensure alignment between needs and design.

Enhanced Communication Efficiency

Our visualization tools simplify the process, making complex ideas more intuitive and reducing repetitive clarifications and time waste.

Minimized Misunderstandings and Errors

Renderings provide a clear reference, reducing risks of production errors caused by misinterpretation of requirements.

Cost Savings

Visualizations in the design phase help minimize rework or corrections, saving costs effectively.

Increased Client Confidence

Showing the product outcome in advance boosts client confidence, speeds up decisions, and increases satisfaction.

Supports Rapid Adjustments and Optimization

Adjust designs quickly based on renderings, aligning the product more closely with customer needs and shortening development cycles.

Price strengths

Centralized Procurement

Our stable customer base and flexible production and stocking policies eliminate concerns about surplus and waste. This enables us to purchase in bulk and reduce costs effectively.

Flexible Management

We require all employees to master at least two production skills, allowing for efficient personnel deployment. This approach effectively addresses workforce shortages caused by order fluctuations and reduces the cost waste associated with hiring additional staff.

Up-to-date Business Philosophy

Our business philosophy is in step with current times, incorporating modern internet-era thinking. By adopting a low-cost strategy to capture market share, we have gained the trust of many customers and passed on real savings to them.

Rigorous Production Management

We aim to produce high-quality, high-yield products that exceed customer expectations by meticulously controlling every production step. Our stringent management system ensures each stage is tightly interconnected, preventing potential issues from arising. This reduces production waste costs for our company.

Copper Film

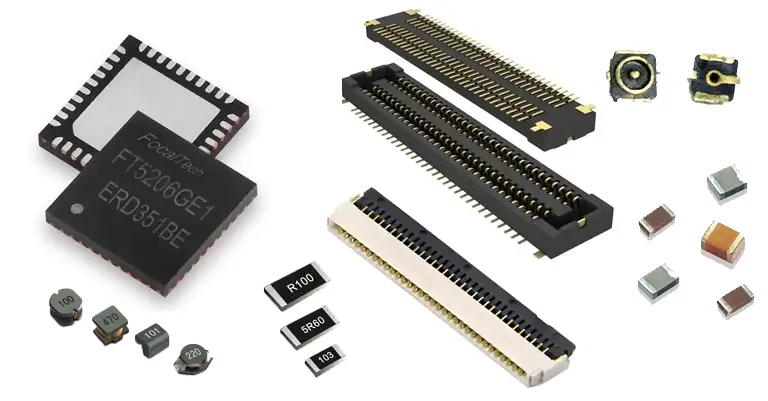

Electronic Materials

Electronic Warehouse

Quality strengths

We first adhere to the principle of quality, meticulously managing every customer and order. Below is our quality control process:

Materials Control

We use Grade A original materials, ensuring quality control starts from raw materials.

Data Optimization

We inspect and optimize design files to align with production requirements, reducing defect rates.

Process Control

Dedicated personnel oversee each process step to meet requirements like hole copper, line width, and impedance.

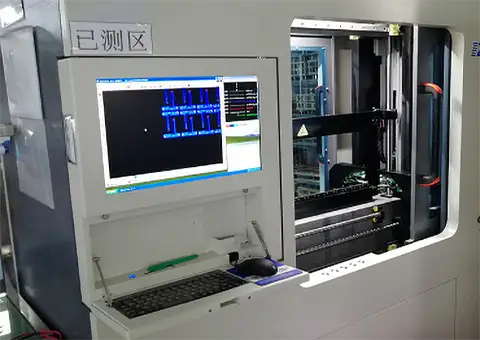

Electrical Testing

We conduct electrical testing to ensure circuits function properly, eliminating defects such as open or short circuits.

SMT Pre-Evaluation

We analyze each product for optimal component placement, ensuring a high first-pass yield.

STM Visual inspection

We inspect each product for defects such as missing components, solder bridges, and false soldering.

Functional Testing

We design test fixtures for functional tests, ensuring each unit is fully functional before delivery.

Packaging Control

Internal cushioning and partitioned placement secure components. We can also meet specific customer packaging requirements.”

Service Advantages

Dedicated Customer

Service Each customer is assigned a dedicated service representative to assist with order tracking and address any concerns promptly.

Product Quality Assurance Service

We guarantee the quality of every order delivered to ensure customer satisfaction and peace of mind. We welcome feedback and will promptly address any issues to resolve customer concerns.

Peripheral Services

Our team includes experienced product managers who can provide valuable advice on product development, particularly in rationalizing structural designs. We assist customers in resolving structural issues to ensure smooth production.

LDI machine

Flying Needle Test

Impedance tester

Pressing Machine

Technology Strengths

Professional engineers

We have professional engineers who conduct feasibility analysis and assessment of client data, optimizing potential risk factors to ensure the smooth production of high-quality products.

Advanced Equipment

Our company is equipped with advanced technology, assuring quality. Some of our equipment includes blind via routing, impedance tester, electrical testing machine, flying probe tester, exposure machine, X-ray equipment, and high-speed pick-and-place machine.

Delivery

We treat every customer equally and process orders in an orderly manner, ensuring guaranteed delivery times.

Sample Delivery Time: 4-10 days (depending on the type)

Bulk Production Time:

Single/Double-sided boards: 5-8 days

Multilayer boards: 10-12 days

With SMT: +2-3 days”