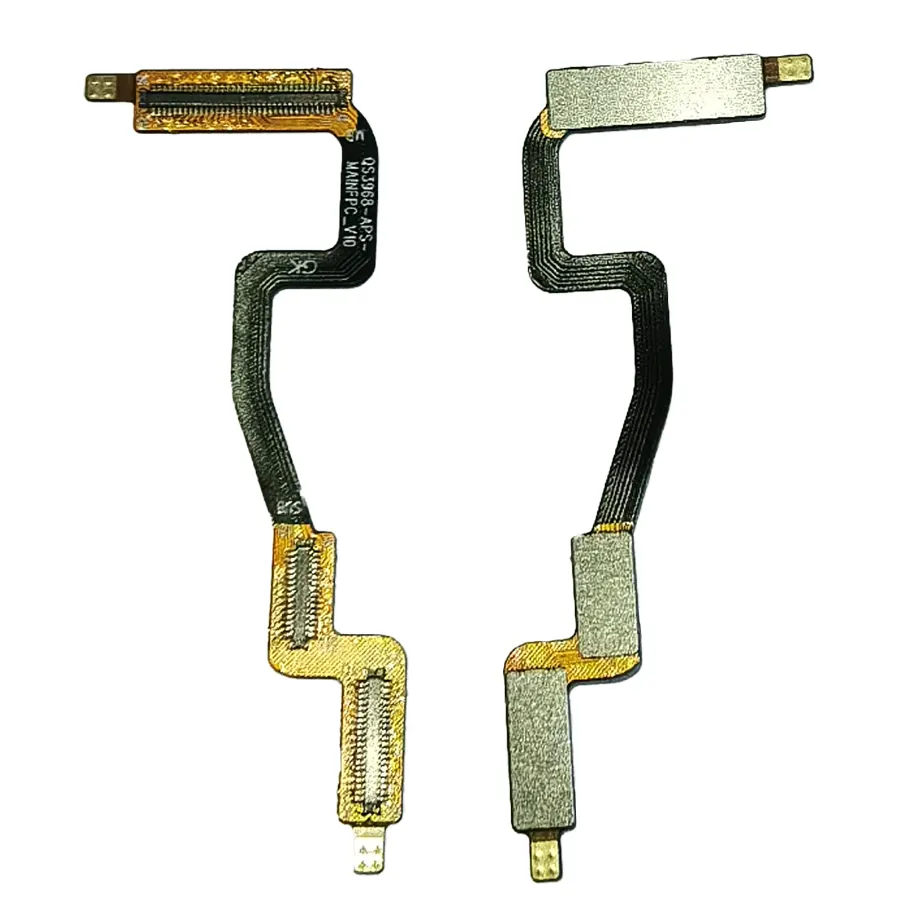

Flip Phone Hinge FPC: The Key Flexible PCB Behind Folding Phones

Now, the old flip phone is back in fashion — this time with a modern twist: today’s smartphones have big screens that fold in half. Shoppers are fans of the slim size and smooth hinge. However, engineers understand that the true star of every folding phone is the hinge flexible PCB (FPC). This crucial component ensures reliable signal transmission and durability during thousands of folds.

In this article, we will look at how flip phone hinge FPCs work. We will discuss their design and how high-quality flexible PCBs help the next generation of foldable devices.

- Material: Polyimide (PI)

- Copper Thickness: 12um

- Minimum Line Width/Spacing: Common Options 0.075-0.15mm

- Via Hole Size:0.1-0.3mm

- Includes Assemblies for Shipment

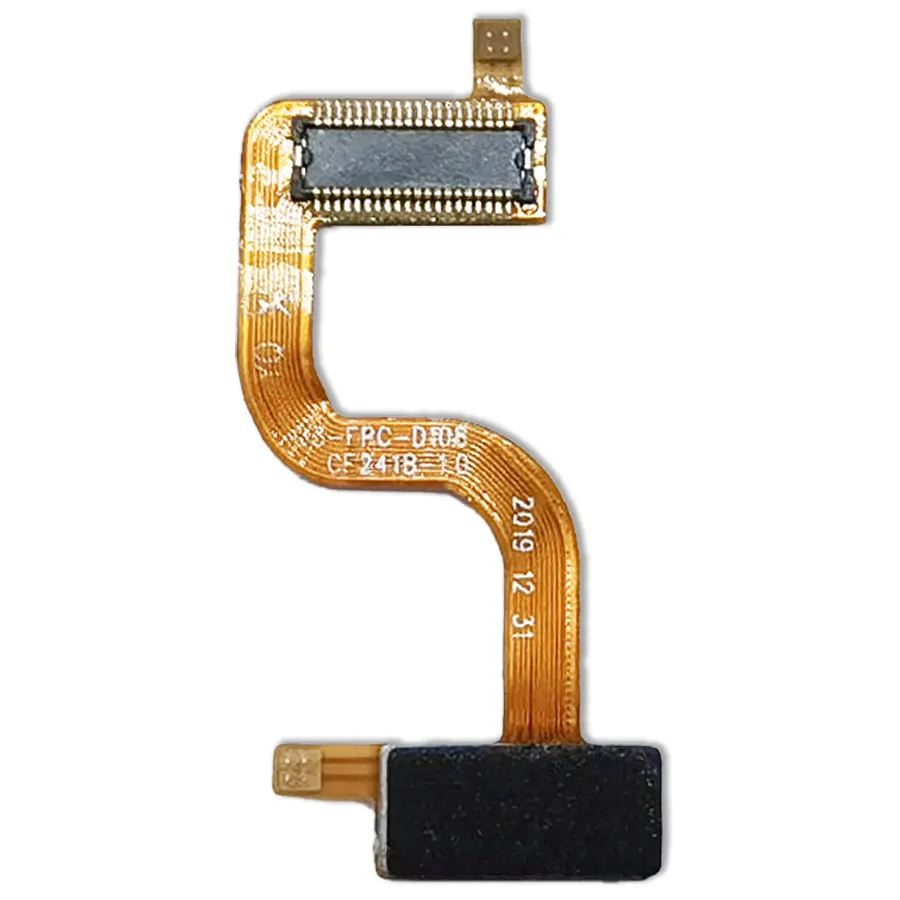

- Appearance Color: Amber, Black

- Common layers: 3-8 layers

- Interface type: BTB

1. What Is a Flip Phone Hinge FPC?

A hinge FPC is a kind of flexible printed circuit board. It connects the two halves of a flip phone using the hinge.

Key functions include:

- Signal Transmission: Transmit the high-speed signals of display, camera, sensors, and fingerprint modules.

- Bend Test Passed: Will never break in tens of thousands of times in the bending test.

- Compact Integration: Fits within the narrow hinge space without adding bulk.

Flip phone FPCs need more mechanical flexibility and a longer bending lifespan than standard flexible circuits in consumer electronics.

2. Why Flexible PCBs Are Essential for Folding Phones

The hinge design of a flip phone is only as reliable as its flexible PCB. Traditional rigid PCBs cannot withstand repeated bending, which makes flex PCBs the only viable solution.

2.1 Benefits of Hinge FPCs

High Flexibility and Durability

- Designed with polyimide (PI) base materials and optimized copper thickness.

- Survives 50,000–200,000 folding cycles in reliability testing.

High-Speed Signal Support

- Transmits high-frequency signals for cameras and displays.

- Minimizes signal loss and impedance mismatch.

Space-Saving Design

- Ultra-thin flex circuits fit within the hinge cavity.

- Supports rigid-flex PCB structures for extra stability.

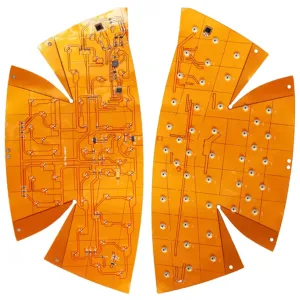

3. Design Considerations for Flip Phone FPCs

When engineers design an FPC for a flip phone, they care much more about durability, signal integrity, and manufacturability.

3.1 Bending Radius and Layer Stack-Up

- Use multi-layer flex circuits with staggered copper traces.

- Maintain a minimum bending radius of 0.5–1.0 mm to prevent copper fatigue.

3.2 Material Selection

- Base Material: High-performance PI for flexibility.

- Copper Foil: Rolled annealed (RA) copper improves bend endurance.

- Coverlay & Adhesive: Heat-resistant to prevent delamination.

3.3 Signal Integrity & EMI Control

- Implement solid ground layers to minimize signal reflections.

- Ensure proper impedance matching for high-speed interfaces.

Using these principles to design FPCs for flip phone hinges will help flip phones last longer. This will bring us closer to the future of folding phones.

4. Applications of Hinge FPCs in Flip Phones

A hinge FPC connects multiple electronic components inside a folding phone, including:

- Main display and sub-display

- Front and rear cameras

- Side buttons and fingerprint sensors

- Battery management modules

This flexible connection enables compact, high-density designs that modern flip phones require.

5. Manufacturing High-Reliability Flip Phone FPCs

Producing a hinge FPC involves advanced manufacturing processes:

- Flexible PCB Fabrication – Multi-layer flex circuits with precise copper plating.

- Reinforcement and Stiffener Bonding – Adds stability where connectors are soldered.

- Bend Life Testing – Ensures durability for thousands of folding cycles.

- Signal Integrity Verification – Confirms low loss and reflection for high-speed data lines.

Proven PCB makers like Gekun can provide specially designed hinge FPCs. These meet the needs of flip phones and folding devices.

Flip phone hinger FPC Specification

| Layers | 3-8 | Type | Flexible |

| Base Material | ED/RA Copper | Customization | YES |

| Copper Thickness | 12um | Finished Thickness | Depending on the number of layers |

| Insulation Material | PI | Reinforcement Material | PI / Steel Sheet |

| Coverlay | Amber, Black | Surface Treatment | ENIG |

| Sample Price | $180 Include SMT | Mold Fee | $650 |

| Sample Quantity | 30PCS | Test Fixture Fee | $150 |

| Sample Time | 7-10Days | Batch Lead Time | 10-15Days |

| Sample Testing | Flying Probe | Batch Testing | Electrical Test |

| Sample Shaping | Laser | Batch Shaping | Die Punching |

FAQS

Q: What is the minimum order quantity?

A: We do not have a minimum order quantity requirement, it depends entirely on the actual needs of the customer.

Q: Can I customize the design?

A: Yes, we offer full customization, including material, layout, and dimensions.

Q: How long does production take?

A: Standard production takes 10–15 working days. Expedited orders can be completed in 7 days.

Q: Do the products meet international standards?

A: Yes, all our products comply with RoHS, REACH, and ISO9001 certifications.

Q: Can I get a sample?

A: Yes, sample orders are available, with a lead time of 5 working days.

Q: Do you offer international shipping?

A: Yes, we use DHL, FedEx, UPS, and other shipping methods worldwide.

Q: How is the price determined?

A: Pricing is based on order quantity, specifications, and complexity. Bulk discounts are available.

Q: What is a hinge FPC in a flip phone?

A hinge FPC is a flexible circuit board. It connects the two parts of a flip phone. This allows for stable signal transmission as the phone folds many times.

Q: How long does a flip phone hinge flex cable last?

High-quality hinge FPCs can withstand 50,000–200,000 bending repetitions according to the material and design.

Q: Can manufacturers customize hinge FPCs for different folding phones?

Yes. Custom-designed hinge FPCs can be tailored for various hinge structures and signal requirements.