How Flexible PCBs Power LED Face Masks

LED Face Mask Market and Technology Overview

LED face masks, also known as red light face masks or light therapy masks, are very popular. Their demand has grown a lot in the beauty and wellness industry. These home devices let users enjoy professional skin care treatments at home. There is no need to visit a clinic.

LED light therapy uses red and near-infrared light waves. It boosts collagen production for healthy skin. This treatment also helps clear acne.

Everyone with a skin problem can have their treatment adjusted. This includes changing treatment times and light wavelengths.

These adjustments help provide personalized light therapy. This device adjusts treatment time and wavelength of light can provide targeted therapy for your skin symptoms.

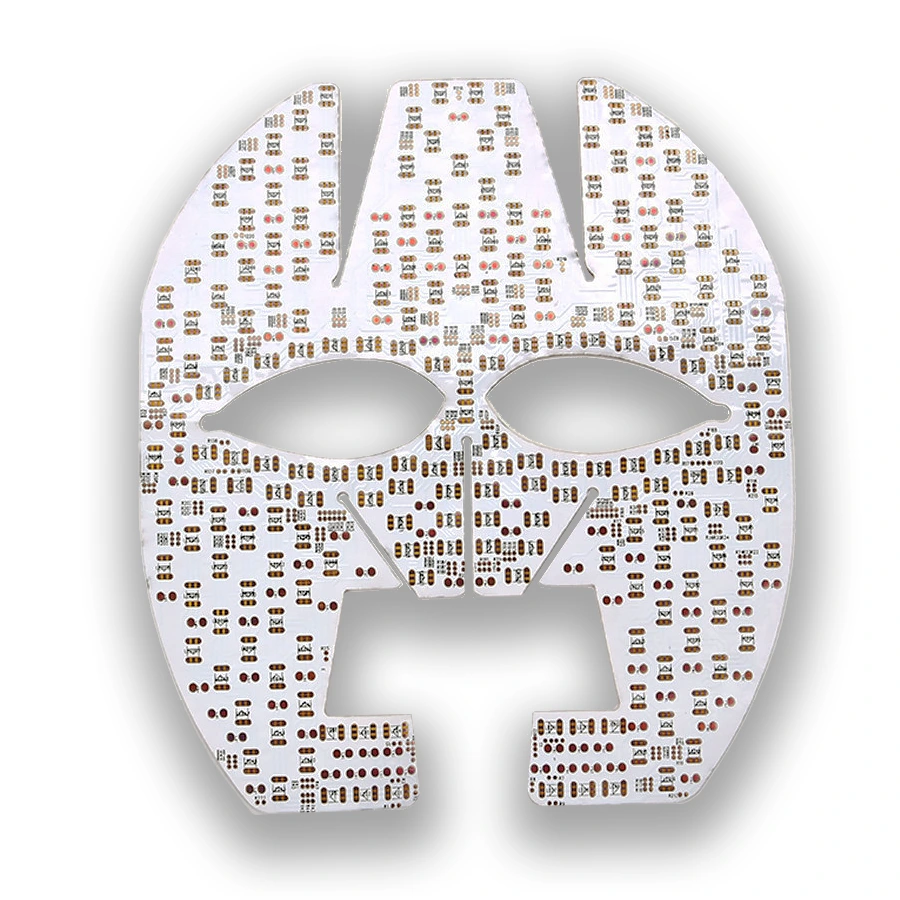

The mask has a comfortable and wearable design. It features a flexcircuit high-density flexible PCB (flex PCB). This allows the LEDs in the mask to work well. The mask is thin and light but strong enough for long-term use.

Why Flexible PCBs Are Essential for Light Therapy Masks

The soft circuit boards (FPCs) are the key components of LED surgical masks and light therapy equipment. Compared to rigid boards, flex circuits provide critical advantages for wearable skin care electronics:

- Ultra-Thin and Lightweight Design

- FPCs are built with polyimide circuit board materials, achieving minimal thickness.

- This keeps the home device comfortable and easy to wear for longer treatment times.

- High-Density LED Integration

- Many electronic parts, like red and infrared light-emitting diodes (LEDs), can fit into high-density flex PCBs.

- They enable precise light wavelength coverage for optimal skin therapy.

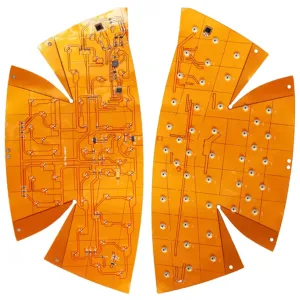

- Bendable and Face-Conforming

- Flex circuits naturally conform to facial curves, ensuring even light therapy distribution.

- The flexibility prevents damage during repeated use and allows for more compact electronic device designs.

- High Temperature and Moisture Resistance

- Light therapy face masks operate in warm and sometimes humid environments.

- They stand up to high temperatures and are resilient in circuit board materials and protective coatings.

By combining these advantages, flex PCBs make LED face masks safe, durable, and effective for at-home skin care treatments.

Inside the Circuit Board Design of LED Face Masks

Creating a reliable LED face mask involves careful flexible circuit board design to ensure safety and consistent performance:

- LED Arrays and Light Wavelength Control

- Multi-layer high-density flex circuits support red and near-infrared LEDs.

- The arrangement of LEDs is optimized with uniform light therapy throughout the mask, resulting in shorter treatment times.

- Electronic Components and Copper Traces

- Electronic components such as resistors and connectors are mounted on flex PCBs for compact design.

- Copper traces and plated through holes maintain stable current flow to every LED.

- Bending Reliability and Thermal Management

- FPCs are designed with a proper bend radius to prevent cracks.

- High temperature resistance ensures long-term performance in medical device conditions.

- Circuit Board Materials and Protective Coating

- Polyimide base materials and coverlay films protect the flex PCB from moisture and skincare products.

- This ensures the electronic device remains reliable even with repeated use.

In short, the flex PCB acts as the nervous system of the light therapy mask, delivering safe and consistent energy to the LEDs.

Manufacturing Flexible PCBs for Light Therapy and Medical Devices

Producing flex circuits for LED face masks and medical devices requires advanced PCB manufacturing processes:

- Material Selection

- High-temperature polyimide for durability and safety

- Copper foil optimized for repeated bending cycles

- High-Density Layer Construction

- Single-layer flex PCB for simple LED masks

- Multi-layer high-density flex PCB for professional-grade red light therapy masks

- Surface Finish & Reliability

- ENIG (Electroless Nickel Immersion Gold) for superior soldering

- Moisture-resistant coatings to protect electronic components

- Comprehensive Quality Testing

- Bend cycle testing to ensure longevity in home devices

- Thermal and current testing for medical device safety

High-quality flexible PCBs ensure that every light therapy face mask is lightweight, effective, and long-lasting.

Key Benefits of Flexible PCBs in Light Therapy Masks

Enables high-density LED arrays for effective red light therapy

Maintains performance in high temperature and humid environments

Supports thin, comfortable face mask designs for long treatment times

Compatible with electronic devices and medical device safety standards

Enhances durability and reliability for home skin care devices

Conclusion & Call to Action

The success of LED face masks, light therapy face masks, and red light face masks depends on the quality of their flexible circuit boards.

Gekun provides:

Custom flex PCB design for wearable beauty and medical devices

Expertise in high-density flex circuits for skin care electronics

Full manufacturing support from prototype to mass production

Contact us today to power your next generation of home skin care devices with reliable, flexible PCB solutions.

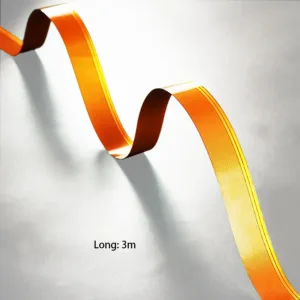

Side Key FPC Specification

| Layers | 1-2 | Type | Flexible |

| Base Material | EDCopper | Customization | YES |

| Copper Thickness | 12-18um | Finished Thickness | 0.1mm |

| Insulation Material | PI | Reinforcement Material | NO |

| Coverlay | Amber, White | Surface Treatment | ENIG |

| Sample Price | $150 | Mold Fee | $650 |

| Sample Quantity | 30PCS | Test Fixture Fee | $150 |

| Sample Time | 6-8Days | Batch Lead Time | 9-10Days |

| Sample Testing | Flying Probe | Batch Testing | Electrical Test |

| Sample Shaping | Laser | Batch Shaping | Die Punching |

Q: What is the minimum order quantity?

A: We do not have a minimum order quantity requirement, it depends entirely on the actual needs of the customer.

Q: Can I customize the design?

A: Yes, we offer full customization, including material, layout, and dimensions.

Q: How long does production take?

A: Standard production takes 10–15 working days. Expedited orders can be completed in 7 days.

Q: Do the products meet international standards?

A: Yes, all our products comply with RoHS, REACH, and ISO9001 certifications.

Q: Can I get a sample?

A: Yes, sample orders are available, with a lead time of 5 working days.

Q: Do you offer international shipping?

A: Yes, we use DHL, FedEx, UPS, and other shipping methods worldwide.

Q: How is the price determined?

A: Pricing is based on order quantity, specifications, and complexity. Bulk discounts are available.