Flexible PCB for HairMax Laser Cap | Wearable Flex Circuits

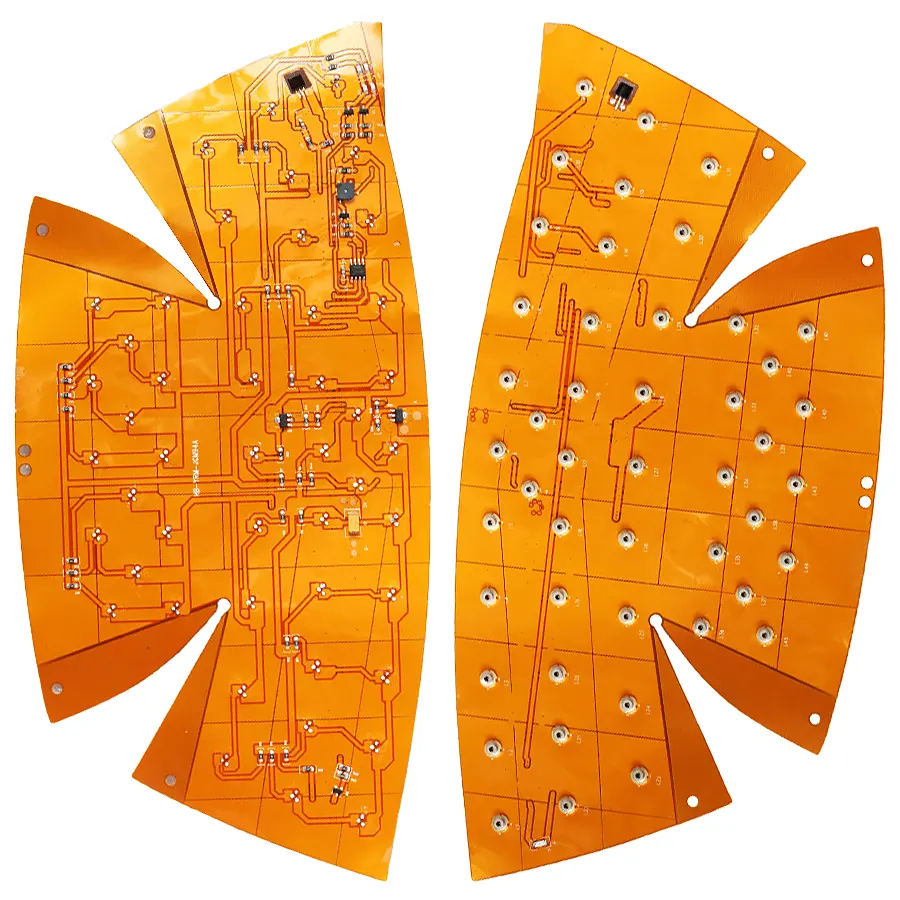

These hair growth caps, like the HairMax Laser Cap, use advanced technology. They deliver lasers effectively and consistently. The key to this innovation is the Flexible PCB (Printed Circuit Board).

It offers a lightweight and durable circuit solution. This allows for precise control of laser diodes while keeping user comfort intact. It is physically flexible, compared to the traditional rigid boards that have been used on older laser growth devices.

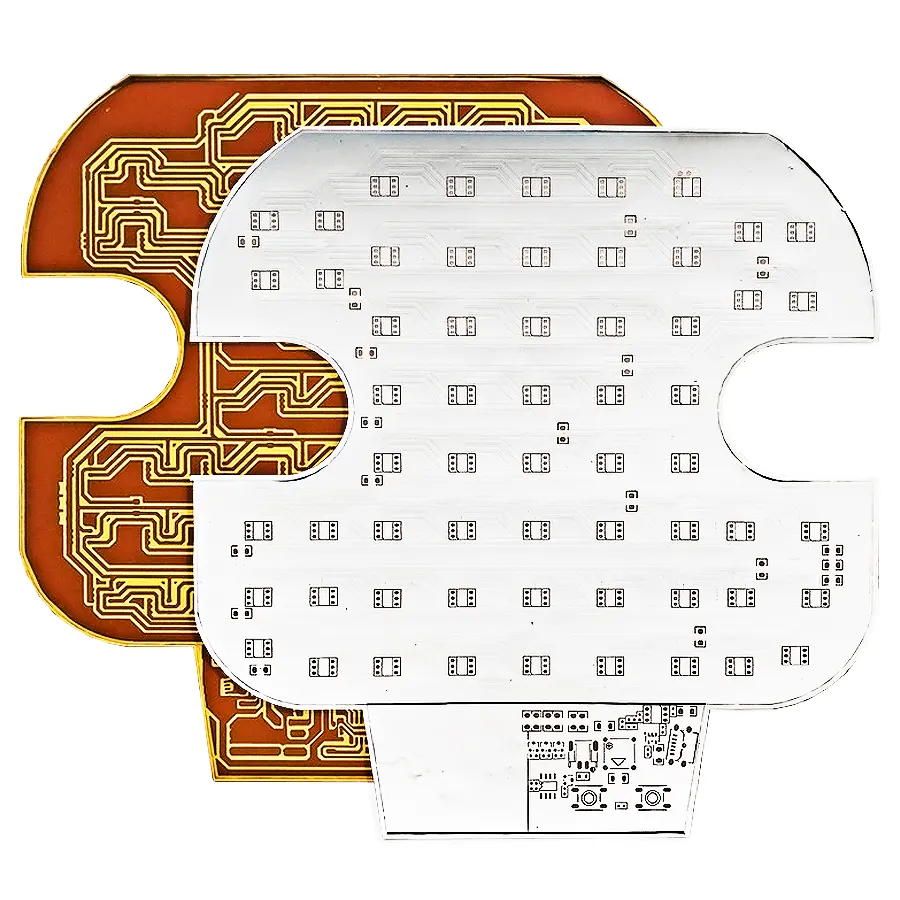

- Material: Polyimide (PI)

- Copper Thickness: 12um-18um

- Common layers: 1-2layers

- Appearance Color: Amber, White

Why Flexible PCBs Are Essential in HairMax Laser Cap

Inside the HairMax Laser Cap200 is a small beanie that contains over 200 medical-grade laser diodes. Fitting so many components into a small space is a big achievement. The circuit board must be very space-efficient and work all the time. There are a few reasons why flexible PCBs fit the requirements for this design style:

- Bendable, form-fitting —the flex circuit conforms to the curvature of the cap so you can maintain your style without feeling like a robot

- Reduced Weight – Flexible PCBs are extremely lightweight and can be used to slim down the size of current wearable designs.

- High-density integration: The flex circuit allows for tight layouts. This helps position the laser diodes accurately across the cap.

- Wearable Use Durability – Flexible PCBs prevent breaking to ensure repeated hair growth treatments in daily use mode.

Technical Advantages of Flexible Circuits in Laser Caps

| Feature | Benefit for HairMax Laser Cap |

|---|---|

| Compact Design | Fits seamlessly inside a slim laser therapy cap |

| Thermal Management | Supports stable laser diode operation at consistent power levels |

| Electrical Reliability | Ensures consistent current flow to each diode |

| Rigid-Flex PCB Options | Combines rigidity for diode mounting and flexibility for curved areas |

| Lightweight Construction | Improves user comfort for long treatment sessions |

This combination of lightweight design, electrical stability, and durability makes flexible PCBs the best solution for medical-grade laser hair therapy devices.

Manufacturing Considerations

Producing flexible printed circuit boards for laser hair growth caps requires advanced manufacturing processes:

- Material Selection- High-quality Polyimide base materials yield heat resistance and flexibility

- Laser Diode Integration – A flex PCB is made, ensuring perfectly placed diodes for even light distribution. ist glUniform LightOutput

- Control of copper layers — Maximized thickness for conductivity and minimal weight, while still maintaining flexibility.

- Rigid-Flex setups — Rigid-flex PCBs offer more strengthening if the plan includes using a laser diode module.

- PCB Electrical reliability TEST to guarantee safe and strong Wearables.

Benefits for End Users

The HairMax Laser Cap uses flexible circuits. This helps both manufacturers and users

Long-Lasting Performance – Users can rely on consistent treatment sessions without electrical failures.

Lightweight Comfort – A flexible design ensures the cap can be worn for extended periods.

Reliable Results – Optimized circuit design ensures every laser diode operates effectively, enhancing hair regrowth outcomes.

Applications Beyond HairMax Laser Cap

The HairMax PowerFlex Laser Cap is a well-known device that uses flexible PCBs. This technology is also found in other wearable medical devices, such as:

LED light therapy masks

Portable medical electronics

Laser therapy helmets

Compact wellness devices

This shows the versatility of flexible PCB technology across the wearable healthcare electronics sector.

Conclusion

The HairMax Laser Cap uses Flexible PCBs. This shows how flex circuit technology helps create small, light, and reliable wearable devices. From laser diodes to rigid-flex PCBs, these circuit boards are important. They help create medical-grade laser hair growth solutions.

As demand for wearable electronics continues to rise, flexible PCBs will remain the foundation of innovation in healthcare technology.

Flexible PCB for HairMax Laser Cap Specification

| Layers | 1-2 | Type | Flexible |

| Base Material | RA Copper | Customization | YES |

| Copper Thickness | 12-18um | Finished Thickness | 0.1mm |

| Insulation Material | PI | Reinforcement Material | NO |

| Coverlay | Amber, White | Surface Treatment | ENIG |

| Sample Price | $150 | Mold Fee | $650 |

| Sample Quantity | 30PCS | Test Fixture Fee | $150 |

| Sample Time | 6-8Days | Batch Lead Time | 9-10Days |

| Sample Testing | Flying Probe | Batch Testing | Electrical Test |

| Sample Shaping | Laser | Batch Shaping | Die Punching |

Q: What is the minimum order quantity?

A: We do not have a minimum order quantity requirement, it depends entirely on the actual needs of the customer.

Q: Can I customize the design?

A: Yes, we offer full customization, including material, layout, and dimensions.

Q: How long does production take?

A: Standard production takes 10–15 working days. Expedited orders can be completed in 7 days.

Q: Do the products meet international standards?

A: Yes, all our products comply with RoHS, REACH, and ISO9001 certifications.

Q: Can I get a sample?

A: Yes, sample orders are available, with a lead time of 5 working days.

Q: Do you offer international shipping?

A: Yes, we use DHL, FedEx, UPS, and other shipping methods worldwide.

Q: How is the price determined?

A: Pricing is based on order quantity, specifications, and complexity. Bulk discounts are available.