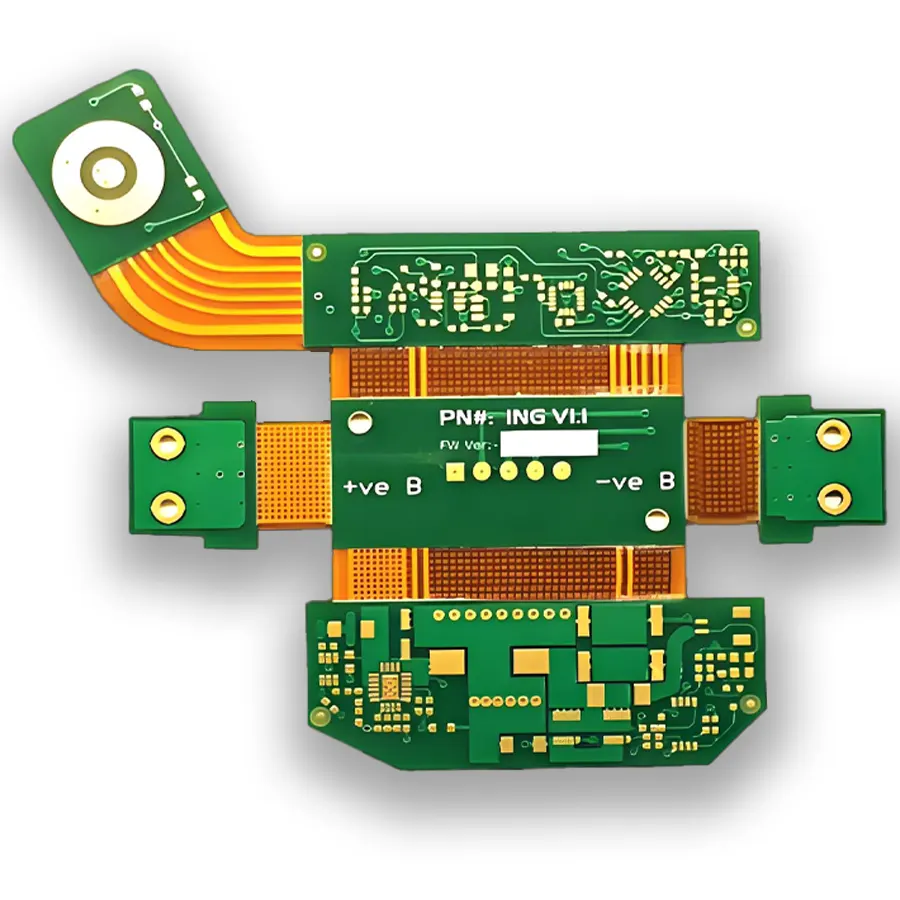

Rigid Flex PCB for Medical Devices

Rigid-flex PCBs for medical devices combine the strengths of rigid and flexible circuits, delivering a reliable and space-efficient solution tailored to meet the stringent demands of the healthcare industry. These PCBs are designed for critical applications, such as diagnostic imaging equipment, wearable health monitors, surgical tools, and implantable devices, offering superior performance and long-term durability in compact designs.

- Material: Polyimide (PI)

- Copper Thickness: Common Options 12um – 35um.

- Minimum Line Width/Spacing: Common Options 0.05-0.2mm

- Includes Assemblies for Shipment

- Appearance Color: Amber, Black

Detailed Description of Medical Device’s Rigid-Flex PCB

A major part of the advancement are rigid-flex PCBs, delivering unmatched reliability, durability, and design flexibility and thus able to help drive the future of medical devices. These hybrid circuits seamlessly integrate rigid and flexible layers to meet the unique demands of medical applications, including space constraints, high reliability, and careful signal transmission.

In diagnostic imaging systems, rigid-flex PCBs provide the necessary structural support for stable connections, ensuring the reliability and reproducibility of diagnostic outputs. For wearable health monitors these devices are lightweight and flexible when combined into a device so that they can be comfortably worn by patients in the long-term. Rigid-flex PCBs provide excellent durability and reliability of surgical tools and implantable devices, enabling safe and effective operations even in extreme conditions.

Sometimes the normal specifications have sufficient ways, but most engineers suggest Rigid-flex PCBs, which have the features of integrating multi-layer with about 16 layers. Furthermore, EMI can be further controlled with the addition of shielding layers, enabling medical devices to function accurately and reliably in sensitive environments.

Gekun has more than a decade’s worth of expertise in producing rigid-flex PCBs for medical devices, emphasizing quality and ingenuity. We tailor designs to accommodate the unique requirements of each application, utilizing leading-edge materials and manufacturing processes that conform to strict medical industry standards. Gekun offers end-to-end solutions from rapid prototype to volume production to ensure successful and timely delivery of reliable and high-performance medical devices to our customers.

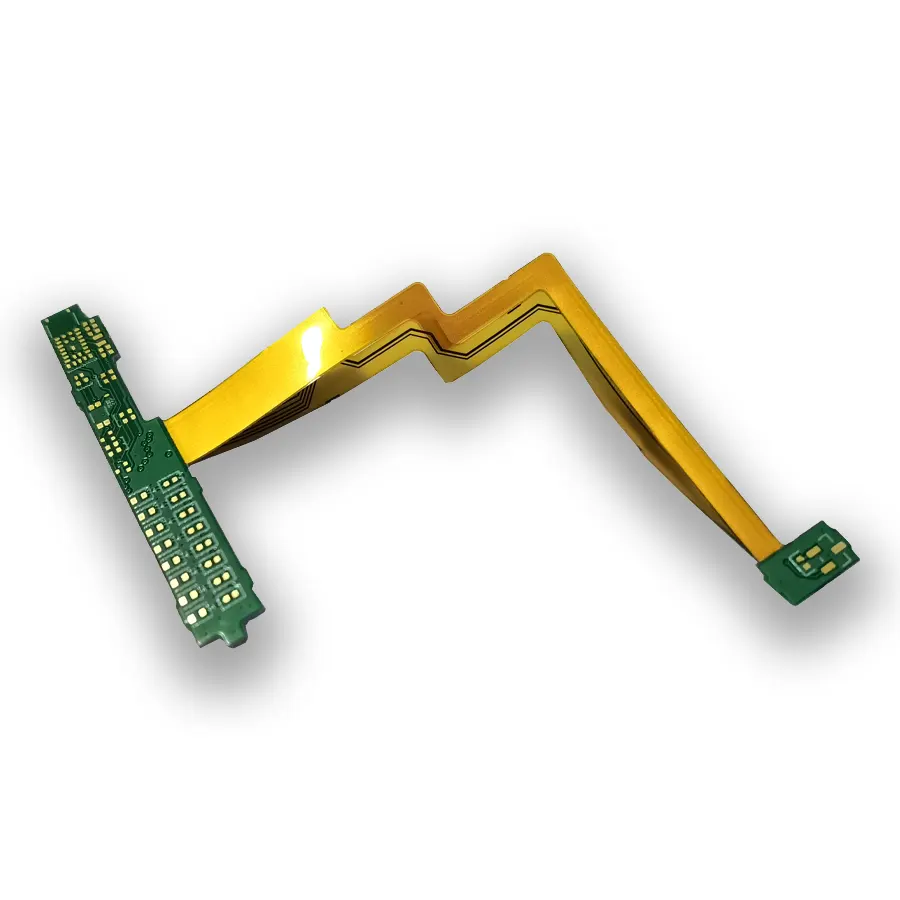

Side Key FPC Specification

| Layers | Double | Type | Flexible |

| Base Material | Electrolytic Copper | Customization | YES |

| Copper Thickness | 12um/18um | Finished Thickness | 0.1mm |

| Insulation Material | PI | Reinforcement Material | PI / Steel Sheet/ FR4 |

| Coverlay | Amber, Black, White | Surface Treatment | ENIG |

| Sample Price | $150 Include SMT | Mold Fee | $200 |

| Sample Quantity | 30PCS | Test Fixture Fee | $150 |

| Sample Time | 6-7Days | Batch Lead Time | 8-10Days |

| Sample Testing | Flying Probe | Batch Testing | Electrical Test |

| Sample Shaping | Laser | Batch Shaping | Die Punching |

Q: What is the minimum order quantity?

A: We do not have a minimum order quantity requirement, it depends entirely on the actual needs of the customer.

Q: Can I customize the design?

A: Yes, we offer full customization, including material, layout, and dimensions.

Q: How long does production take?

A: Standard production takes 10–15 working days. Expedited orders can be completed in 7 days.

Q: Do the products meet international standards?

A: Yes, all our products comply with RoHS, REACH, and ISO9001 certifications.

Q: Can I get a sample?

A: Yes, sample orders are available, with a lead time of 5 working days.

Q: Do you offer international shipping?

A: Yes, we use DHL, FedEx, UPS, and other shipping methods worldwide.

Q: How is the price determined?

A: Pricing is based on order quantity, specifications, and complexity. Bulk discounts are available.