Rigid PCB vs Flexible PCB: Which Wins for Your Applications?

Introduction

PCBs are the nervous system of nearly all modern electronics. People can use them to make everyday things like wireless earbuds and vital medical devices like pacemakers.

Prismark Research says the global PCB market will hit $89.7 billion by 2027. Flexible PCB applications will grow at 8.3% each year. This growth is faster than traditional rigid circuit boards.

Engineers face a pivotal decision early in product design: flexible printed circuit board or conventional rigid PCB? This choice impacts:

- Product durability: Will the board survive 5 years in a vibrating car engine?

- Manufacturing cost: Does the $0.50/sq.in savings justify design compromises?

- Time-to-market: Can your flex PCB manufacturer meet aggressive deadlines?

Understanding the difference between flexible PCBs and rigid circuit boards is important. This knowledge helps engineers and buyers choose the best option for their technology. Each has unique benefits for specific uses, environments, and performance requirements.

Reference: PRINTED CIRCUIT REPORT

What Are Flexible and Rigid PCBs?

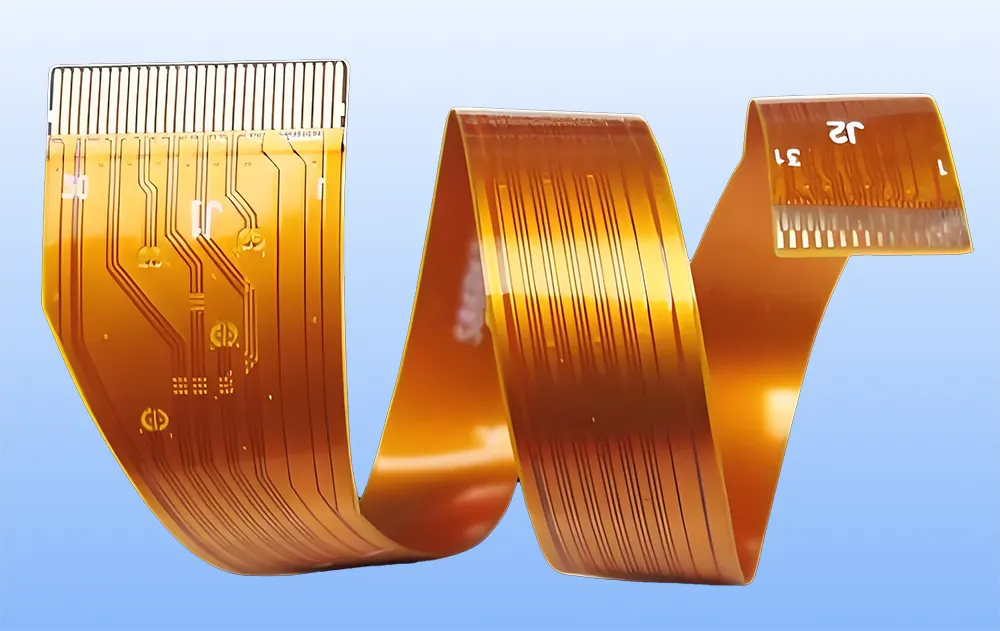

Flexible PCBs Explained

Flexible PCB

Manufacturers make flexible printed circuit boards (or flex PCBs) on bendable base materials. This material can be polyimide or PET film. These materials let the board bend and fit into complex shapes. This makes them great for small or foldable electronic devices.

These circuits are usually made on layers of conductors. They are pressed between layers of flexible material. They are both electrically connected and mechanically flexible.

Rigid PCBs Overview

Rigid PCB

In contrast, rigid circuit boards are constructed from materials like FR4 (glass-reinforced epoxy), which do not allow bending. Rigid PCBs provide strong support. These circuit boards work well for devices that carry heavy parts or require mounting in a fixed position. They are the most common types used in large-scale industrial and consumer electronics applications.

Where Are Flexible PCBs Used?

Flexible PCB Applications

Engineers widely adopt flexible PCBs in applications where space, weight, and motion are design constraints. Below are examples of sectors leveraging flexible PCB applications:

- Wearable tech: Flex circuits keep their shape. This is why manufacturers create fitness trackers, smartwatches, and medical patches using them.

- Automotive systems: Manufacturers apply these in harsh environmental conditions, including engine compartments.Here in a little space and with high temperatures.

- Medical equipment: Portable diagnostic instruments and medical equipment, such as single-use endoscopes, utilise ultra-low profile flexible substrates.

- Drones and aerospace: Wearable flex PCBs remove weight and resist vibration. They give you a nice balance of strength and flexibility.

- Consumer electronics: Smartphones, laptops, and foldable screens widely use flexible printed circuit boards. These boards conserve space and make for easier navigation.

Application Selection Guide

| Application | Recommended PCB Type | Justification | Example Product |

|---|---|---|---|

| Wearable Devices | Flexible PCB | Conforms to body curves | Fitness tracker sensor module |

| Automotive Electronics | Rigid Flex PCB | Withstands high temperature + tight space | Car camera module |

| Industrial Controls | Rigid PCB | Requires heatsinks and mechanical stability | PLC mainboard |

| Medical Endoscopy | Flexible PCB | Navigates <3mm diameter curved paths | Disposable endoscope imaging unit |

| Drones | Rigid Flex PCB | Lightweight + resists airflow vibration | Flight control system |

| Home Appliances | Rigid PCB | Cost-sensitive + static mounting | Microwave control panel |

Types of Flexible and Rigid Flex PCBs

Understanding the varieties helps in making informed design choices:

- Single-sided flexible PCBs: Ideal for low-cost, simple designs with minimal component density.

- Double-sided flexible PCBs: Feature plated through holes to connect top and bottom layers, allowing more complex routing.

- Multilayer flexible PCBs: Composed of several conducting layers, perfect for high-density electronic applications.

- Rigid flex PCBs: Combine rigid circuit boards and flex layers, delivering hybrid benefits. These are increasingly used in applications requiring space efficiency and structural stability.

Flexible Materials vs Rigid Substrates

The choice of base material plays a vital role in PCB performance:

- Flexible materials such as polyimide can endure mechanical stress and repetitive bending without cracking. They also tolerate high-temperature environments.

- Rigid substrates help with heat dissipation and are cheaper to make in large amounts. This makes them great for electronic products that do not need to move.

| Feature | Flexible PCB | Rigid PCB |

|---|---|---|

| Material | Polyimide / PET film | Glass fiber / Epoxy resin |

| Flexibility | Bendable (5+ million cycles) | Non-bendable |

| Thickness | 0.1–0.3 mm | 0.4–3.2 mm |

| Cost (after scale) | $0.3–5/sq.in | $0.1–2/sq.in |

| Thermal Resistance | Suitable for high temperatures | Moderate heat tolerance |

| Component Density | Supports high-density layouts | High, but limited by a 2D layout |

Performance Comparison – Flex vs Rigid

Let’s analyze performance aspects across various environments:

- Durability in motion: Flex PCBs outperform rigid types in dynamic applications, lasting millions of bend cycles.

- Thermal management: Rigid boards manage moderate heat well. Flexible PCBs can use heat-resistant materials for tough environments.

- Space Savings: Engineers can package flex circuits into 3 dimensions to fit tight spaces, saving valuable board space.

- Reliability: Flex designs have fewer interconnects. This means there are fewer points of failure, leading to a longer system life.

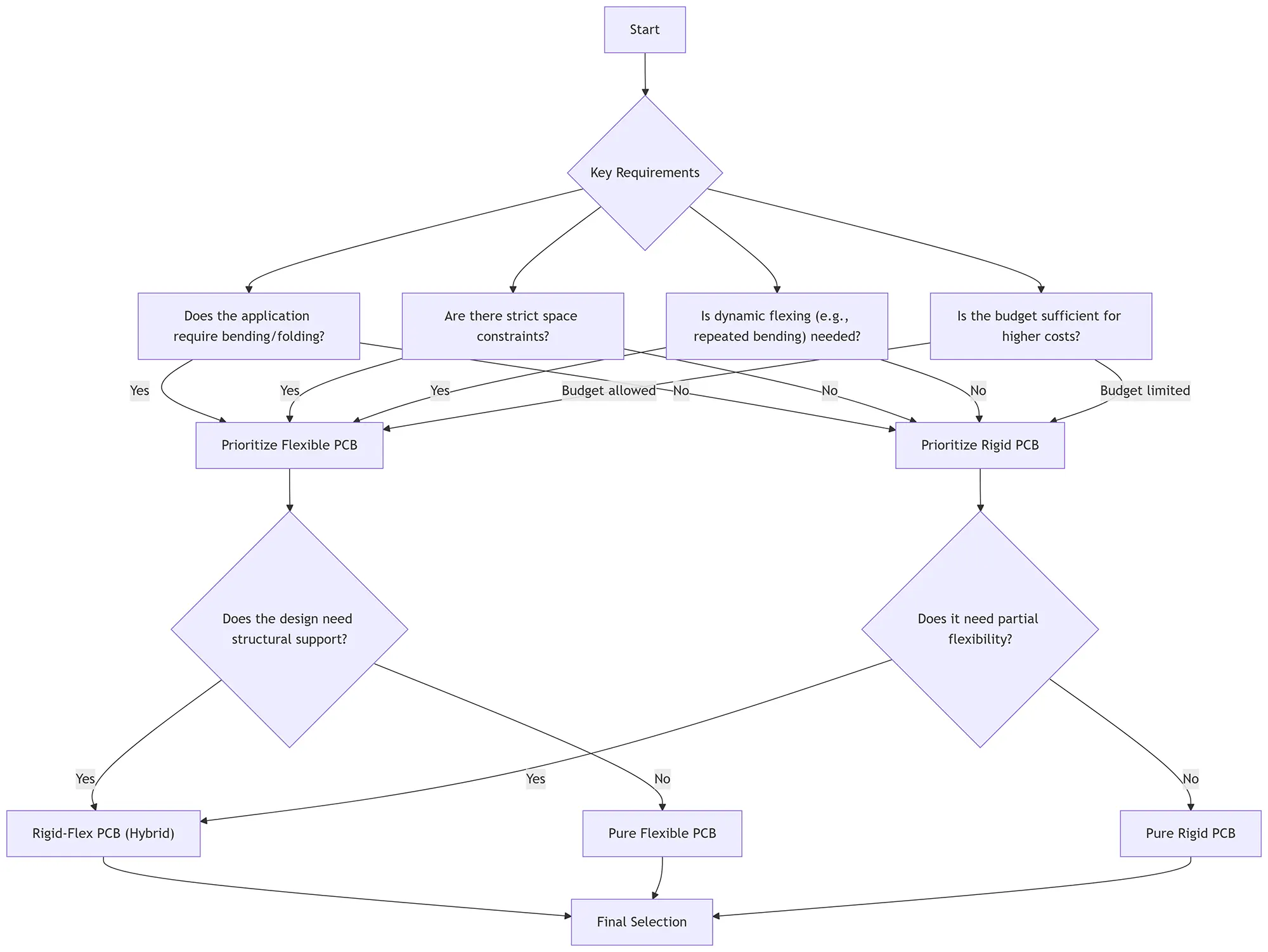

Conclusion

PCB Selection Flowchart: Flexible vs Rigid Design Decision Tree

Deciding between a flexible PCB and a rigid PCB depends on your specific needs. Designers use flexible PCBs in tight spaces and for moving applications. Rigid PCBs are better for stable and cost-effective environments. Rigid-flex PCB applications fill the gap by combining structural rigidity and design flexibility together. Knowing where Flexible PCBs are used helps improve product life and the performance of many electronic devices. If you want to make a flexible PCB for your next device, think about a few important things. First, consider the base material. Next, look at the conducting layers. Also, be aware of challenges like high temperatures and harsh environments. Doing so helps ensure your final electronic product is reliable, efficient, and future-ready.

Leave A Comment