Cleaning PCB Boards: Expert Practical Tips & Best Practices

Why Cleaning PCB Boards Is Crucial

PCBs accumulate flux residues, solder paste, dust, and oils during manufacturing or field use. Left unaddressed, these contaminants can trap moisture and create conductive paths, leading to short circuits and accelerated corrosion.

Dust and particulates act as insulators, reducing heat dissipation and causing overheating of sensitive electronic components. Over time, dirty boards have more component failures and shorter service life. This makes regular cleaning very important.

Common Contaminants and Risks

- Flux Residue & Solder Paste: Acidic residues can attract moisture. This can weaken adhesion and cause lift-off or heel cracks in solder joints.

- Dust & Particulate Matter: Ambient dust can absorb humidity and conduct leakage currents, resulting in random failures.

- Oils & Fingerprints: Handling leaves oils that degrade over time and compromise solderability.

- Corrosion Products: Untreated contaminants lead to metal oxidation on pads and traces, causing unreliable contacts.

Professional Cleaning Solutions and Equipment

Isopropyl Alcohol (IPA) and PCB Cleaners

PCB Cleaner

Isopropyl alcohol (≥ 90% IPA) is the most common cleaning solution for PCBs and electronic circuit boards. It evaporates quickly, leaves little residue, and effectively removes flux and grease. Many commercial PCB cleaners and circuit board sprays mix high-purity IPA with de-ionized water and surfactants. This helps improve wetting and penetration into small crevices.

Ultrasonic Cleaning

Ultrasonic Cleaning Machine

Ultrasonic cleaning uses high-frequency sound waves in a cleaning solution. These waves create bubbles that gently remove dirt from even the smallest parts of a PCB. Advantages include:

- Non-destructive action that preserves delicate solder joints and fragile components.

- Uniform cleaning of hidden areas, under SMDs, and within through-holes.

- Reduced reliance on harsh chemicals, enabling eco-friendly cleaning solutions.

- Make sure everything works well together. Some MEMS devices can get damaged by strong cavitation. High-density boards might need frequency-swept ultrasonic baths to prevent hot spots.

Reference post: Ultrasonic Cleaning of PCBs with Crystals

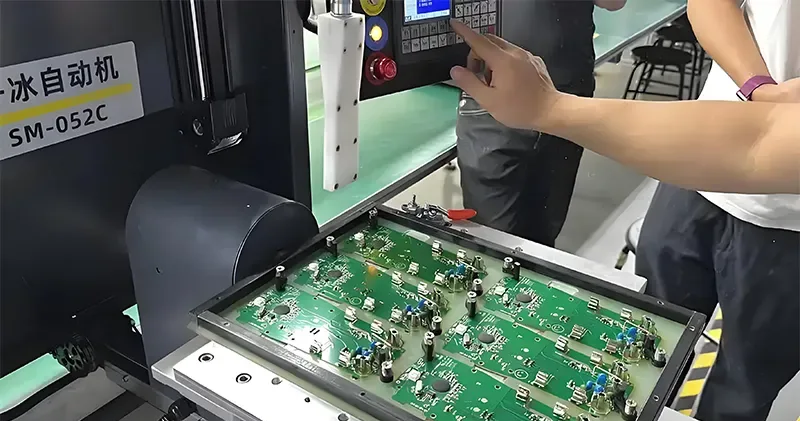

PCB Cleaning Machines

PCB Cleaning Machines

In high-volume production, automated PCB board cleaning machines provide consistent output. These machines include spray-in-air, spray-under-immersion, and conveyorized systems. They also offer data logging for process control.

- Spray-in-Air: Best for small to medium runs; cost-effective.

- Spray-Under-Immersion: For water-soluble fluxes; uses DI water and low-VOC detergents.

- Ultrasonic Batch Cleaners: Ideal for delicate or dense assemblies.

Cleaning Methods and Agents

Cleaning Solutions and Agents

- Water-Based Cleaning Agents: They have a low flash point. They are eco-friendly and work well on most no-clean and water-soluble flux residues.

- Solvent-Based: High solvency for rosin and adhesives; often used in vapor degreasers. Select solutions rated for PCBs to avoid residue.

- Specialty Agents: Custom cleaning solutions formulated for specific flux chemistries (e.g., lead-free SAC305 fluxes).

Reference post: Ensuring Quality and Reliability: The Essential Role of Meticulous Assembly Cleaning

Compressed Air and Dry the Board

After rinsing, use compressed air to dry the board and remove trapped droplets, especially under components. Heat-oven or hot-air stations (50–70 °C) can further ensure moisture removal. Proper drying prevents electrochemical migration and early dielectric breakdown.

Step-by-Step Guide: How to Clean a PCB

- Power Down & Disassemble

- Unplug and dismantle the device; remove batteries and sensitive modules to avoid damage.

- Initial Dust Removal

- Blow off loose particles using compressed air or an electronics vacuum. Keep the nozzle ~5 cm away to prevent component displacement.

- Apply Cleaning Agent

- Spray IPA or dedicated PCB board cleaner spray generously over the board surface.

- For stubborn flux, use a soft-bristle brush dipped in cleaning agent and clean a PCB in gentle circular strokes.

- Ultrasonic or Machine Cleaning (if available)

- Submerge in an ultrasonic bath with the appropriate solution. Run for 3–5 minutes at the recommended frequency.

- Alternatively, feed through an automated PCB cleaning machine.

- Rinse & Dry

Reference post: The Importance of Drying in PCB Cleaning

- Rinse with DI water or pure IPA to remove residues.

- Dry the board using compressed air, then oven or hot-air station for 10–15 minutes.

- Inspect & Reassemble

- Visually inspect for remaining contaminants. Reinstall modules once completely dry, then power on and verify functionality.

DIY and Alternative Cleaning Methods

For field or home repairs:

- Everclear (95% ethanol) in lieu of IPA; ensure ventilation and flame safety.

- White Vinegar + DI Water: Mild acid dissolves corrosion; follow up with baking soda rinse and thorough drying.

- WD-40? Not recommended — leaves oily film that attracts dust and degrades dielectric performance.

Preventing Component Failures: Maintenance Tips

- Schedule regular cleanings based on operating environment (dusty vs. cleanroom).

- Use filtration and positive pressure in enclosures to minimize airborne particulates.

- Monitor humidity; use conformal coatings for boards in high-humidity or corrosive atmospheres.

- Test after cleaning to catch early component failures due to hidden moisture or residues.

FAQs

Q1: What is the best solution for cleaning PCB boards?

A: At least 90% isopropyl alcohol (IPA) is the industry standard. You can mix it with DI water and surfactants in cleaning solutions.

Q2: How do you clean circuit board contacts?

A: Use a cotton swab dipped in IPA to gently wipe contacts, then blow dry with compressed air to ensure no residue remains.

Q3: How to clean a PCB at home without alcohol?

A: Use a mix of vinegar and DI water for light residues. Scrub gently with a soft brush. Rinse with baking soda to neutralize. Dry the board completely.

Q4: Can ultrasonic cleaning damage PCBs?

– Ultrasonic cleaning is safe when done correctly.

– This means using a frequency sweep and the right solution.

– It is also important to avoid metal-on-metal contact. It effectively removes flux and particles without damaging components.

Tips: The above method is also suitable for flexible circuit boards.

Contact Gekun today for a free consultation. Learn how our PCB cleaning solutions can improve your manufacturing quality. We can help reduce costly rework and ensure your printed circuit boards work perfectly every time.

Leave A Comment