PCB Lamination Process Explained: From Rigid Boards to Flex PCB Manufacturing

Introduction: Why Lamination Matters in PCB Fabrication

Lamination is a key step in making PCBs. It affects how strong and well the finished PCB works.

The lamination process is key to making multilayer boards. This includes both rigid boards and flexible circuit boards. It determines how well the layers stick together. It also affects how they handle high temperatures and tough conditions.

For flexible PCBs and rigid flex PCBs, lamination requires even more precision. Using thin copper foil and special adhesive layers is challenging.

However, it is important for advanced designs. Unique coverlay materials also play a key role in this process. This article gives a full guide to PCB lamination. It focuses on how it relates to flex PCB manufacturing processes.

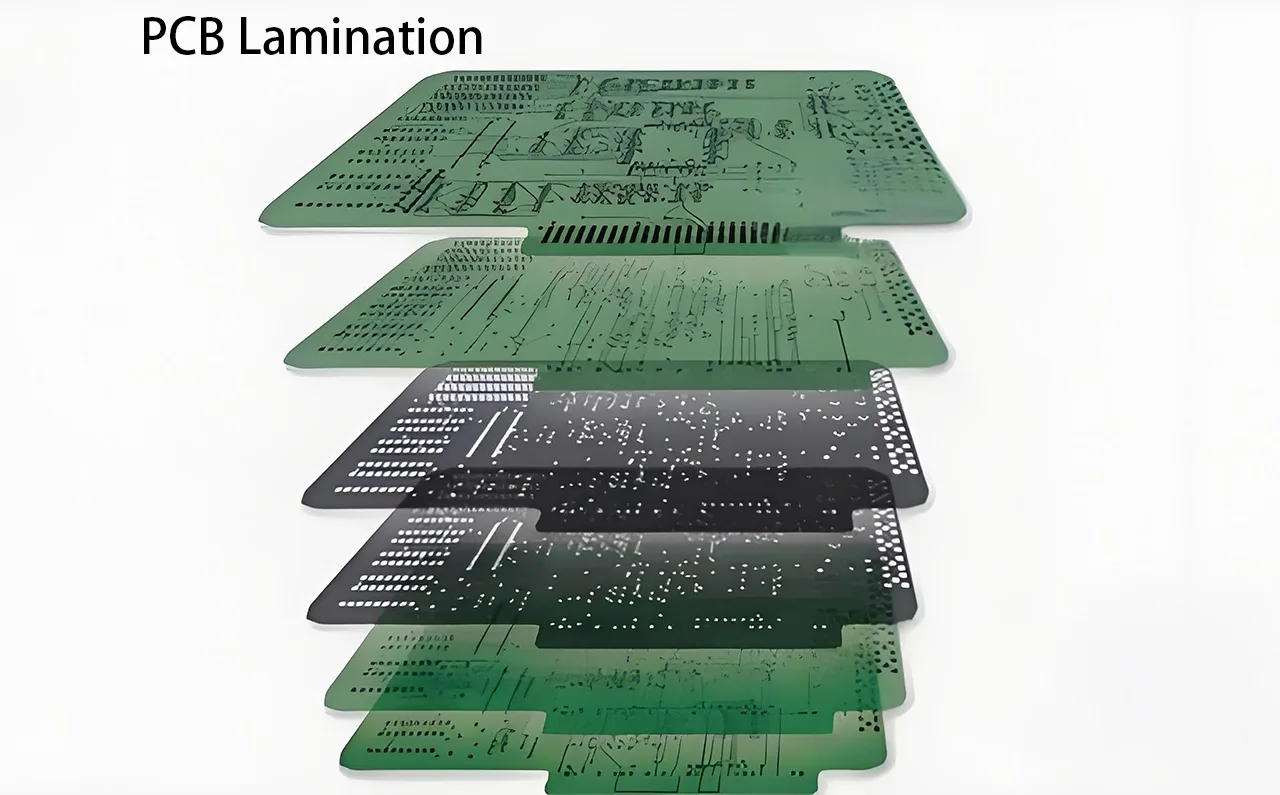

What is PCB Lamination?

In short, PCB laminate is made by compressing layers of copper and insulating materials. This is done at a specific temperature and high pressure. The goal is to create one strong printed circuit board. It should have good electrical conductivity and mechanical strength.

Key materials used in lamination include:

- Copper foil – the conductive base for creating circuit traces.

- Prepreg or adhesive layers – bonding materials that hold layers together.

- Core or flexible base material – which can be FR4 for rigid boards or polyimide for a flexible PCB.

- Coverlay material or solder mask – to protect circuit patterns and provide insulation.

The lamination process is more than just stacking. It requires precise alignment, removal of air pockets, and strong adhesion between layers.

Types of PCB Lamination

Different circuit designs require different lamination techniques. The most common types include:

1. Standard Rigid PCB Lamination

It is used in both consumer and industrial electronics. It has layers of prepreg pressed with copper foil at high temperature. The result is a solid, long-lasting fabric; however, it is quite rigid.

2. Multilayer PCB Lamination

Here, more than four copper layers are stacked and laminated together. The process involves multiple press cycles, ensuring accurate circuit design alignment and high reliability.

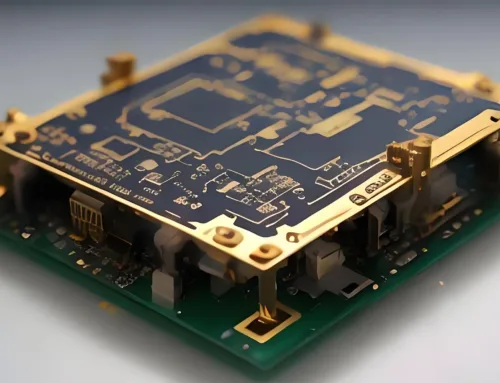

3. High-Density and HDI PCB Lamination

Microvia lamination and sophisticated surface finish processes are necessary in high-density designs. These PCBs are frequently found in smartphones, laptops, and other high-performance electronics.

4. Rigid Flex PCB Lamination

Microvia lamination and sophisticated surface finish processes are necessary in high-density designs. These PCBs are frequently found in smartphones, laptops, and other high-performance electronics.

5. Flexible PCB Lamination

It involves polyimide films, ultra-thin copper foil, and specialized bond processes to fabricate flexible printed circuits. Compared to hard boards, it requires less pressure and a lower temperature for laminating. This helps prevent wrinkles or peeling in the substrate from high heat.

Flex PCB Lamination Process Explained

Lamination Machine

The flex pcb manufacturing process requires unique techniques compared to standard rigid boards. Below are the major steps involved:

Layer Preparation

Thin copper foil and polyimide-based films are cut to precise dimensions.

Adhesive layers are applied to ensure proper bonding.

Stack-Up Alignment

The circuit design must be aligned with high accuracy.

Optical registration systems prevent misalignment of thin, flexible sheets.

Heat and Pressure Application

The stack is subjected to carefully controlled temperature and pressure.

This activates the adhesives and bonds the copper to the base material.

Coverlay Material Application

Instead of a standard solder mask, flexible circuits use a polyimide coverlay material.

It provides insulation while allowing flexibility in bending areas.

Final Surface Finish and Electrical Testing

A surface finish (ENIG, OSP, or immersion tin) is applied for solderability.

Electrical testing ensures strong electrical conductivity and mechanical reliability.

This specialized lamination process enables flexible printed circuits to withstand repeated bending, high-density interconnections, and high temperature environments.

Comparing Rigid vs Flex PCB Lamination

| Feature | Rigid PCB Lamination | Flexible PCB Lamination |

|---|---|---|

| Base Material | FR4 or epoxy glass | Polyimide or PET film |

| Protective Layer | Solder mask | Coverlay material |

| Bonding | Prepreg layers | Adhesive layers |

| Copper Thickness | Typically thicker | Ultra-thin copper foil |

| Temperature and Pressure | Higher ranges | More controlled, lower pressure |

| Applications | Consumer, industrial devices | Wearables, aerospace, medical |

This comparison highlights why flexible circuit boards require more delicate processing, especially in applications demanding lightweight, compact, and durable electronics.

Applications of Flex PCB Lamination

The unique properties of flexible pcbs make them ideal for advanced industries:

Consumer Electronics: Smartphones, foldable displays, and wearable devices.

Automotive Systems: Sensor modules and infotainment systems.

Medical Devices: Implantable electronics and diagnostic equipment.

Aerospace and Defense: High-reliability designs requiring lightweight printed circuit boards.

In all these industries, the flex PCB manufacturing process gives you reliable electrical performance. It also offers high temperature and mechanical strength.

Conclusion

Lamination is the key process for all types of multilayer PCBs. This includes simple rigid boards, flexible printed circuit boards, and rigid-flex PCBs.

Engineers and purchasing agents can look at the rigid flex PCB fabrication processes. This will help them choose the best solution for their needs.

With this understanding, choosing the right materials and controlling temperature and pressure will ensure reliable electrical conductivity. Using the right coverlay material or solder mask is also important for long-term performance.

At Gekun we specialize in flexible pcb lamination for industries that require high density, lightweight and durable solutions. As boards become more complex, accurate lamination will remain essential for circuit design and high-end PCB fabrication.

Other release post:

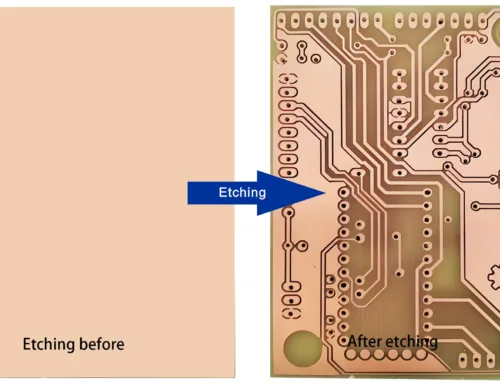

PCB Etching Process: Flexible PCB & Rigid Flex Manufacturing

Leave A Comment