PCB Surface Finish Types Explained: Best Options for Flexible PCBs

Introduction: Why Surface Finish Matters in PCB Fabrication

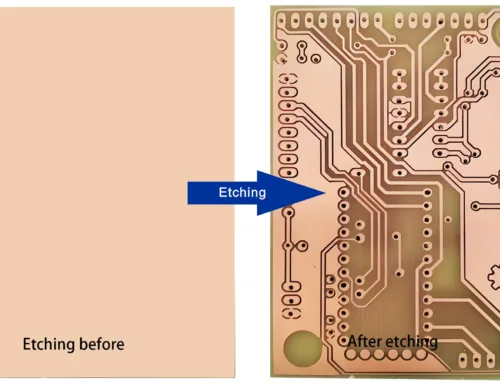

Every circuit board requires protection for its copper traces. Without a reliable finish, exposed copper quickly oxidizes, reducing electrical conductivity and making soldering nearly impossible. This is why PCB surface finishes are a critical step in PCB fabrication.

Surface finishes serve as a protective layer. They create a flat surface for attaching fine-pitch components. These finishes also help protect the board. They extend the board’s shelf life and maintain performance in high-temperature situations.

Choosing the right surface finish is important for all PCBs; however, it is even more critical for flexible printed circuit boards and flex PCBs. This is primarily because these boards have thin substrates, bending needs, and special materials that create new challenges. Therefore, this article looks at the most common PCB surface finishes, and it also explains how they work with flexible PCBs and rigid flex circuits.

What is a PCB Surface Finish?

A pcb surface finish is a coating applied over the copper surface of a circuit board. Its main functions include:

Preventing oxidation of exposed copper

Providing a solderable surface during assembly

Ensuring smooth and flat surfaces for advanced circuit design

Extending the shelf life of the PCB

We can achieve the appropriate surface finish depending on the type of board, assembly process, and application. For example, a flex circuit for a medical device might use electroless nickel immersion gold (ENIG). In contrast, a cheaper consumer product can use organic solderability preservative (OSP).

Common Types of PCB Surface Finishes

1. Hot Air Solder Leveling (HASL)

Hot air solder leveling HASL is one of the oldest and most cost-effective finishes. The board is dipped in molten solder and leveled with hot air knives.

Advantages: Inexpensive, good protection, reliable for standard applications

Disadvantages: Uneven thickness, not suitable for fine pitch components, may stress flexible PCBs due to high heat exposure

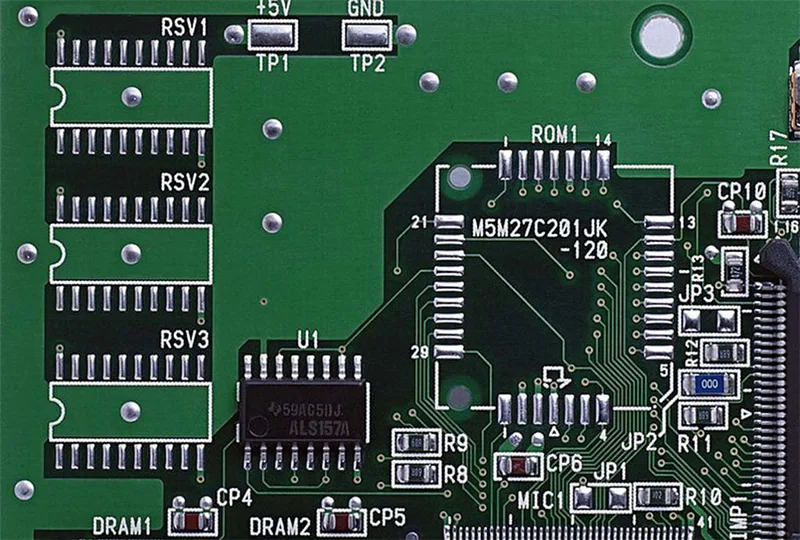

2. Electroless Nickel Immersion Gold (ENIG)

Surface ENIG technology

Electroless nickel immersion gold ENIG is one of the most popular modern PCB surface finishes. It applies a layer of nickel over the copper surface, followed by a thin gold coating.

Advantages: Excellent flat surfaces, long shelf life, compatible with fine pitch components, stable under high temperature

Disadvantages: Higher cost, risk of “black pad” defects if not controlled properly

3. Organic Solderability Preservative (OSP)

Surface OSP technology

Organic solderability preservative OSP is a thin, organic coating that protects exposed copper from oxidation.

Advantages: Low cost, environmentally friendly, smooth flat surfaces

Disadvantages: Limited shelf life, less durable during multiple reflow cycles, not ideal for long-term storage

4. Immersion Silver

Immersion silver applies a thin layer of silver directly onto the copper traces.

Advantages: Excellent electrical performance, good for high-frequency circuits, smooth flat surfaces

Disadvantages: Tarnishes easily if improperly handled, sensitive to the environment

5. Immersion Tin

Immersion Tin technology

Immersion tin creates a thin, uniform coating of tin over the copper surface.

Advantages: Very flat, suitable for fine pitch components, relatively low cost

Disadvantages: Limited shelf life, risk of “tin whiskers,” and less resistant to high-temperature environments

6. Electroless Nickel Electroless Palladium (ENEPIG)

An advanced option, electroless nickel electroless palladium with immersion gold, offers high reliability.

Advantages: Excellent solderability, superior wire-bonding capability, long shelf life

Disadvantages: Expensive, mainly used in high-reliability industries such as aerospace and medical devices

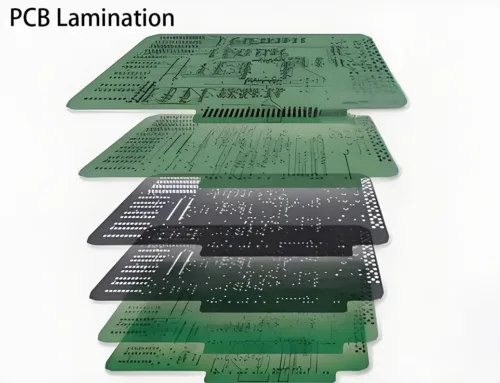

Flexible PCB Surface Finish: Special Considerations

We have unique circuit board materials. We offer flexible and rigid-flex circuit boards. These are made from DuPont™ Pyralux® flex base material. If we face a challenge, we solve it with these boards. A bend, flex, and high-temp living environment. Flex PCBs are not rigid: they twist, they bend, and must perform in extreme heat & stress.

Key factors include:

Heat Sensitivity

Hot air solder leveling (HASL) uses molten solder on the thin polyimide substrate. This process can damage or warp flexible PCBs.

Alternatives like ENIG or OSP are more suitable.

Flat Surfaces for Fine Pitch Components

Modern flex circuits often require fine pitch components, making smooth finishes essential.

ENIG and immersion tin are preferred for providing flat surfaces.

Shelf Life Requirements

Products that need to be stored for a long time, like those in aerospace or defense, need finishes that last a long time. Examples of these finishes are ENIG and ENEPIG.

For consumer devices with fast turnover, OSP may be sufficient.

Environmental Exposure

Devices exposed to high temperatures or humidity benefit from ENIG or immersion silver, which maintains reliable solderability.

Comparing Rigid vs Flexible PCB Surface Finishes

| Finish Type | Rigid PCB Suitability | Flexible PCB Suitability | Key Notes |

|---|---|---|---|

| HASL | Common and low cost | Not recommended | Heat can damage thin substrates |

| ENIG | Excellent for rigid boards | Highly suitable | Provides flat surfaces, great for fine pitch |

| OSP | Cost-effective option | Works for simple flex PCBs | Limited shelf life |

| Immersion Silver | Reliable electrical performance | Suitable but environment-sensitive | Requires controlled storage |

| Immersion Tin | Good for fine pitch | Applicable with caution | Risk of tin whiskers |

| ENEPIG | Premium applications | Suitable for high-end flex circuits | High cost, best for aerospace/medical |

How to Select the Right Surface Finish for Flexible PCBs

Choosing the right finish for a flexible PCB depends on:

Application environment: Will the board face high temperature, vibration, or humidity?

Component requirements: Are there fine pitch components requiring ultra-smooth surfaces?

Cost vs performance: Is this for mass-market electronics or high-reliability aerospace applications?

Storage expectations: Does the board need a long shelf life before assembly?

For example:

Consumer wearables → OSP or immersion tin for cost efficiency

Medical devices → ENEPIG or ENIG for reliability and longevity

Automotive sensors → ENIG for durability under high temperature

Aerospace electronics → ENEPIG for maximum performance

Applications of Flexible PCB Surface Finishes

Wearables & Consumer Electronics: Compact designs using flex circuits and requiring smooth flat surfaces.

Automotive Systems: Reliability under vibration and high temperatures.

Medical Devices: Long shelf life and biocompatibility in advanced flexible printed circuit boards.

Aerospace & Defense: High-end boards with electroless nickel electroless palladium for maximum reliability.

Conclusion

Choosing a PCB surface finish can greatly impact the quality, performance, and reliability of a circuit board. Additionally, it can affect the cost. Generally, rigid substrates can take almost any finish or treatment. However, flexible PCBs and flex circuits need careful selection. This is because the substrate is thin, and as a result, the product will bend during use. Moreover, these circuits often work in tough environments.

Consequently, flexible PCBs are frequently treated with finishes, such as electroless nickel immersion gold (ENIG), immersion silver, or organic solderability preservative (OSP). Although hot air solder leveling (HASL) can be used, it is usually not practical for most flexible designs due to the heat.

Therefore, engineers and purchasing professionals should understand that the surface finishes on flex circuits impact several factors. For example, these include solderability, shelf life, and electrical performance. Ultimately, these factors are very important for successfully completing the fabrication of a flex PCB. At Gekun, we are experts in picking the right finish for every need. So whether you need a disposable device or reliable aerospace electronics, you can count on us.

Leave A Comment