Flexible PCB for Displays: Enabling Next-Generation Screen Technology

Displays today are being designed to be thinner, lighter, with more flexible. Smartphones, tablets, OLED TVs — advanced screen technology relies on robust electronic interconnects. The flexible PCB technology is called Flexible Printed Circuit (FPC).

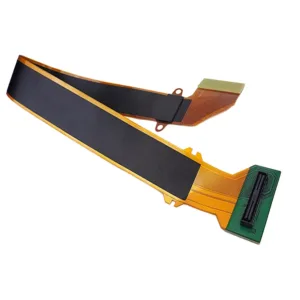

They allow for small and light designs of today’s LCD, OLED, and LED modules. They provide important electrical paths in the display FPC cable.

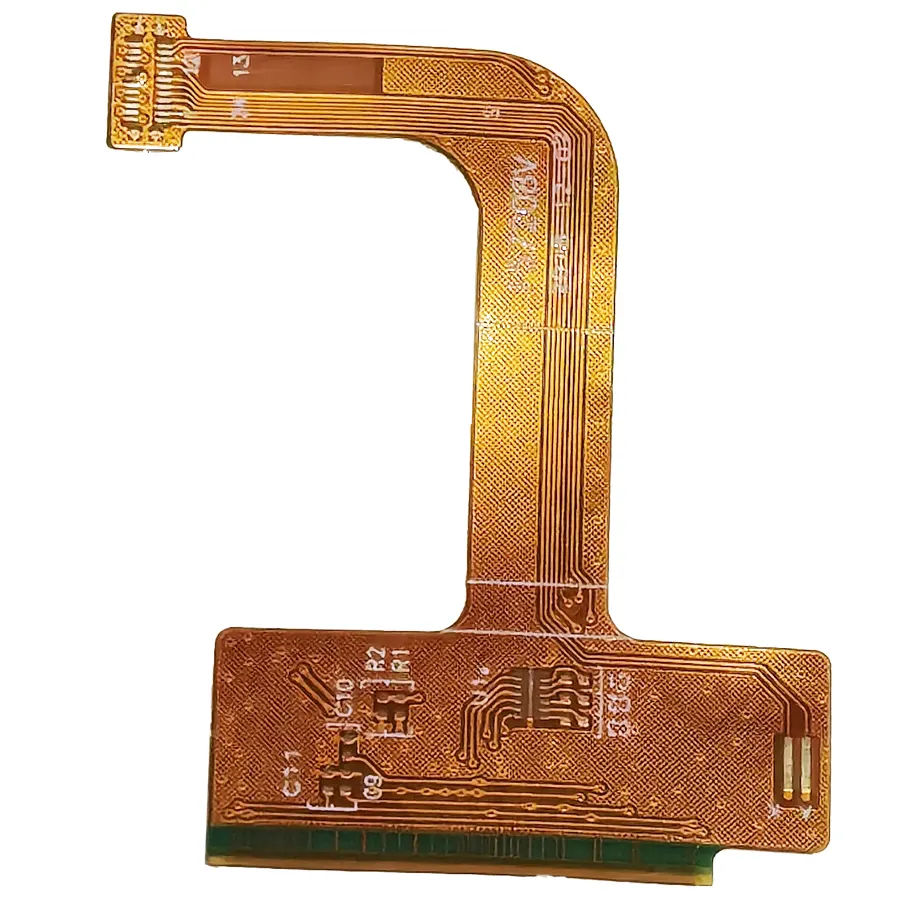

These flex circuits can bend to fit the unique shapes of today’s LCD FPC connectors and OLED display panels. They support high performance and innovative designs, unlike standard rigid boards

- Material: Polyimide (PI)

- Copper Thickness: Common Options 12um or 18um.

- Minimum Line Width/Spacing: Common Options 0.05-0.2mm

- Via Hole Size: 0.1- 0.2 mm

- Includes Assemblies for Shipment

- Appearance Color: Amber, Black

Why Flexible PCBs Are Essential for Displays

Display evolution necessitates high-density interconnect capabilities on circuit boards that are lightweight and flexible. They must contact these through special FPCs (Flexible PCBs or FFC) as they offer the following characteristics:

Conform to Curved Designs – Important for OLED and foldable screens, which do not necessarily allow rigid PCBs.

Space-Saving and Lightweight – The thin, flexible PCB or LCD flex cable usually fits into slim screen modules.

- Enhanced Reliability – without needing multiple connectors, which results in signal disruption, improving signal integrity.

Support High-Speed Data – FPC LCD connectors maintain stable performance in high-frequency display transmission.

Enhance Thermal Management – Copper layers and FPC films for touch screens allow effective heat dissipation.

Technical Advantages of Flexible PCBs in Display Screens

| Feature | Benefit for Display Applications |

|---|---|

| Thin & Lightweight | Fits slim LCD modules and portable devices |

| Bendability | Enables foldable OLED and wearable displays |

| High-Density Routing | Supports FPC LCD connectors and fine-pitch circuits |

| Signal Reliability | Ensures consistent LCD FPC display performance |

| Heat Resistance | Withstands backlight and LED panel heat |

| Rigid-Flex Integration | Combines FPC flexibility with rigid stability |

This combination of features makes flexible printed circuit boards for LCDs and OLEDs essential for modern screen technology.

Types of Displays Using Flexible PCBs

1. LCD Displays

FPC LCD displays rely on FPC connectors for LCD modules to connect glass substrates with driver ICs. LCD flex cable replacements are common in smartphones, tablets, and industrial monitors.

2. OLED Displays

Flexible OLEDs use OLED FPC connectors and custom FPC for display panels. These support curved, foldable, and wearable screen designs.

3. LED Displays

Large LED panels often use FPC manufacturers for LED screens. They provide display FPC cables that make wiring easier and help with heat dissipation.

4. Touchscreens

FPC films for touch screens and FPC flex cables for screens connect sensors to controllers, ensuring precise input response.

5. Wearable Displays

Smartwatches, AR glasses, and medical monitors use flexible printed circuit boards or flexible flat cables (FFC). These solutions help with compact and strong integration.

Manufacturing Considerations

Producing reliable display FPCs requires advanced processes:

Material Selection – Polyimide-based FPC films maintain durability and flexibility.

Copper Thickness Control – Optimized copper layers balance conductivity and flexibility.

HDI Technology – Enables fine-pitch LCD FPC connectors for high-resolution displays.

Rigid-Flex PCB Options – Used in modules that combine connectors with flexible screen interconnects.

Reliability Testing – Includes bending cycles, thermal shock, and signal integrity testing.

Applications of Flexible PCBs in Display Technology

Flexible PCBs, also known as display FPC cables, are widely used in:

Consumer Electronics – Smartphones, tablets, laptops, TVs (LCD FPC displays)

Automotive Displays – Dashboards, infotainment, HUDs using custom FPC for display panels

Medical Devices – Portable monitors and wearable displays with FPC LCD connectors

Industrial Equipment – Control panels and large LED displays with FPC cables

Wearables – Smartwatches, VR headsets, fitness trackers using FPC flex cables for screens

FAQs

Q1: Why are Flexible PCBs used in LCD and OLED displays?

Flexible PCBs, or FPCs, are thin and bendable connections. They help create lightweight and compact display designs, including curved shapes.

Q2: What is the difference between an FPC and an FFC cable?

The FPC (Flexible Printed Circuit) has etched copper tracks on a polyimide base. The FFC (Flexible Flat Cable) is usually made of flat, laminated wires. In displays, FPCs offer higher reliability for fine-pitch LCD FPC connectors.

Q3: What is an FPC LCD connector?

The FPC LCD connector is a fine-pitch interface. It connects the display FPC to the main PCB. This connection helps maintain fast signal transmission in LCD and OLED modules

Q4: Can FPCs be replaced in LCD displays?

Yes. Smartphones and tablets have a problem with LCD flex cable replacements. This is due to original FPC cable fatigue or damage.

Q5: Who manufactures FPCs for LED screens?

Gekun can handle FPCS related to αmini LED display modules. We can offer custom value-added FPCS. This ensures durability, fine-pitch connections, and excellent thermal management for a better user experience.

Conclusion

In many markets, like consumer, medical, and industrial, there is a strong need for displays. These displays should be lightweight, reliable, and have good optical features. LCD FPC displays follow this trend. They use high-quality flexible PCBs (FPC). They also use OLED FPC connectors and reliable display FPC cables.

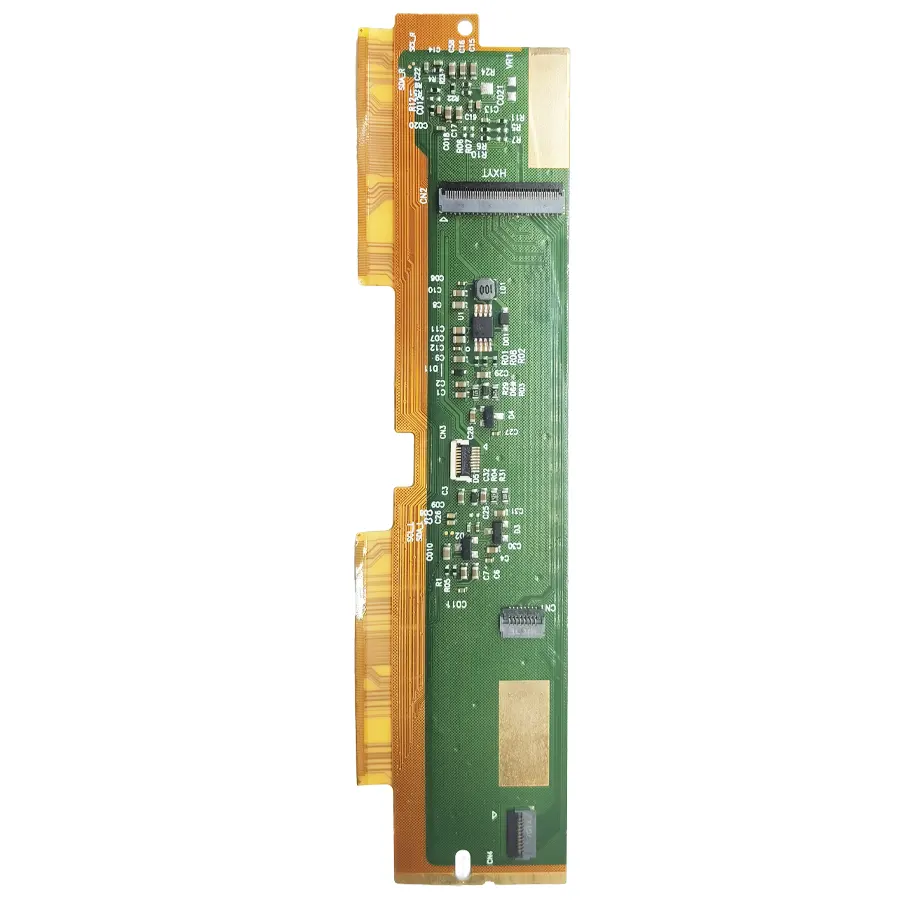

Display FPC Specification

| Layers | Double | Type | Flexible |

| Base Material | Electrolytic Copper | Customization | YES |

| Copper Thickness | 12um/18um | Finished Thickness | 0.1mm |

| Insulation Material | PI | Reinforcement Material | PI / Steel Sheet/ FR4 |

| Coverlay | Amber, Black, White | Surface Treatment | ENIG |

| Sample Price | $150 Include SMT | Mold Fee | $200 |

| Sample Quantity | 30PCS | Test Fixture Fee | $150 |

| Sample Time | 6-7Days | Batch Lead Time | 8-10Days |

| Sample Testing | Flying Probe | Batch Testing | Electrical Test |

| Sample Shaping | Laser | Batch Shaping | Die Punching |

Why Choose Our Display FPC Solutions?

1. High-Density Interconnect (HDI) Technology

Ultra-thin FPC LCD display circuits with fine-pitch traces (up to 0.05mm).

Supports 4K/8K displays and high-speed data transmission.

2. Reliable FPC Display Connectors

Robust LCD display, FPC connectors for vibration-resistant connections.

Customizable layouts for OLED, AMOLED, and TFT displays.

3. Durability & Flexibility

Bend-resistant materials (PI/PET) for foldable and curved displays.

Dynamic flex life exceeding 100,000 cycles.

4. Custom FPC Display Solutions

Tailored designs for display FPC connector integration.

Rapid prototyping and mass production support.

About Flexible PCB for Display FAQS

Q: What is the role of an FPC in LCD displays?

A: FPCs in displays transmit signals between the LCD panel and control board, replacing bulky wiring with compact, flexible circuits.

Q: Can you customize FPC display connectors?

A: Yes! We design LCD display FPC connectors to match your mechanical and electrical requirements.

Q: How do FPCs improve display performance?

A: They reduce EMI, enhance signal speed, and enable slimmer display designs vs. rigid PCBs.