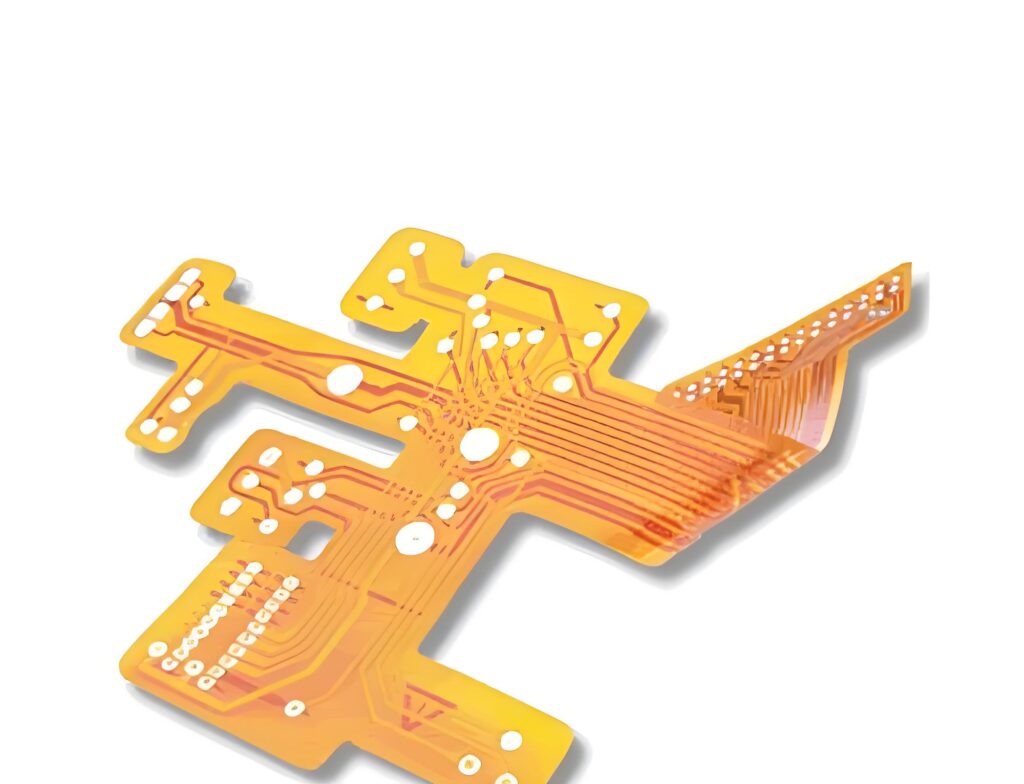

Flexible PCB Cost 2025: Calculator, Price per Sq.Inch & Low-Cost Manufacturing Guide

How Much Does a Flexible PCB Cost?

The average flexible PCB cost ranges from 0.5to30+ per square inch in 2025, depending on layer count, materials, and order volume. This guide reveals cost calculation methods, compares flex vs rigid PCB cost structures, and provides actionable strategies for low-cost PCB fabrication.

Key Cost Drivers of Flexible PCBs

1. PCB Cost Per Square Inch Breakdown

| Parameter | Cost Impact ($/sq.in) | Details |

|---|---|---|

| 1-Layer Flex PCB | 0.5 – 1.2 | Polyimide base, 1oz copper |

| 2-Layer Flex PCB | 1.8 – 3.5 | Adhesive-based construction |

| 4-Layer Rigid-Flex | 4.0 – 8.0 | Laser-drilled microvias |

| HDI Flex PCB | 12.0 – 30.0 | 50μm line width/spacing |

*Prototype orders (1-5pcs) typically incur 200%-300% price premiums.*

2. Material Costs (2025 Benchmark)

Base Films:

Polyimide (PI): 0.15/sq.in(Standard)→0.22/sq.in (High-Tg)

Liquid Crystal Polymer (LCP): $0.40/sq.in

NEW PCT Film: $0.18/sq.in (30% cheaper than LCP with similar Dk=2.9)

Adhesives:

Acrylic: $0.03/sq.in

Epoxy: $0.07/sq.in (Better thermal resistance)

Flexible PCB Cost Calculator Methodology

Use this formula for preliminary estimates:

Example Calculation:

4-layer rigid-flex PCB (10sq.in, 50pcs)

Material: PI + Epoxy ($0.25/sq.in)

Process: $3.2/sq.in (Includes laser drilling)

Tooling: 280(One−time)→∗∗UnitCost∗∗=[(0.25×1.3 + 3.2)×10]+(280/50) = $38.65/pc

For precise quotes, please contact us!

Low-Cost Flexible PCB Strategies

1. Volume Optimization

| Order Quantity | Price Reduction | Tactics |

|---|---|---|

| 10-50pcs | 15%-20% | Panelization sharing |

| 100-500pcs | 25%-35% | Standardized specs |

| 1000+pcs | 40%-50% | Roll-to-Roll production |

2. Cost-Saving Material Alternatives

Replace LCP with PCT: Saves 20%-30% for frequencies <15GHz

Use Adhesiveless Construction: Reduces layer thickness by 25% and cost by $0.8/sq.in

Opt for OSP Finish: 0.05/sq.invsENIG′s0.12/sq.in

Flex vs Rigid PCB Cost Comparison

| Feature | Flexible PCB | Rigid PCB | Cost Difference |

|---|---|---|---|

| Base Material | Polyimide ($0.15) | FR4 ($0.04) | +275% |

| 4-Layer Processing | $3.2/sq.in | $1.5/sq.in | +113% |

| Minimum Bend Radius | 6x layer thickness | Not applicable | N/A |

| Tooling Fees | $200-$500 | $80-$200 | +150% |

Data source: 2025 IPC Flexible Circuits Quarterly Report

Low-Volume PCB Assembly Cost Factors

For orders under 100pcs:

Setup Fees: 50−150 per batch

Component Sourcing:

Passive components: +0.02−0.15/pc

BGAs: +1.5−4.0/pc (X-ray inspection required)

Turnkey Service Premium: 18%-25% of PCB cost

Pro Tip: Combine multiple designs in panel form to reduce low-volume PCB assembly costs by 30%-40%.

FAQs: Flexible PCB Pricing

Q: How much does a custom PCB cost per unit?

A: Custom flexible PCB unit costs range from:

Prototypes: 12−45/pc (5-10pcs)

Mid-volume: 4−15/pc (100-500pcs)

Mass production: 0.8−3/pc (1000+pcs)

Q: What’s cheaper: flex PCB DIY vs professional manufacturing?

A: DIY flex PCB kits cost 120−400 for basic setups but:

Limited to 1-2 layers

Minimum line width: 8mil vs professional 2mil

No impedance control

*Professional manufacturing becomes cost-effective above 20pcs.*

PCB Cost Reduction Case Study

Client: Wearable ECG Monitor Startup

| Challenge | Solution | Cost Impact |

|---|---|---|

| High 4-layer flex cost | Switch to 2-layer with HDI | -32% |

| $18/sq.in material cost | Adopt PCT film | -28% |

| 60-day lead time | Partner with Vietnam factory | -15% |

| Total Savings | -75% |

Gekun’s advantages include:

State-of-the-art manufacturing facilities.

Expert engineering support.

Flexible pricing options for both low-volume prototypes and large-scale production.

On-time delivery and exceptional customer service.

The price of a flexible PCB is influenced by various factors, including material selection, manufacturing complexity, order volume, and supplier location. Understanding these factors helps in making informed decisions to manage costs effectively without sacrificing quality.

When you choose Gekun as your flexible PCB supplier, you’re not just getting a product; you’re partnering with an industry leader committed to providing top-tier solutions at competitive prices. Contact us today to learn more about our flexible PCB offerings.

By keeping your specific requirements in mind and choosing the right supplier, you can optimize both the cost and performance of your flexible PCB.

Leave A Comment