Rigid-Flex Printed Circuit Board Solutions

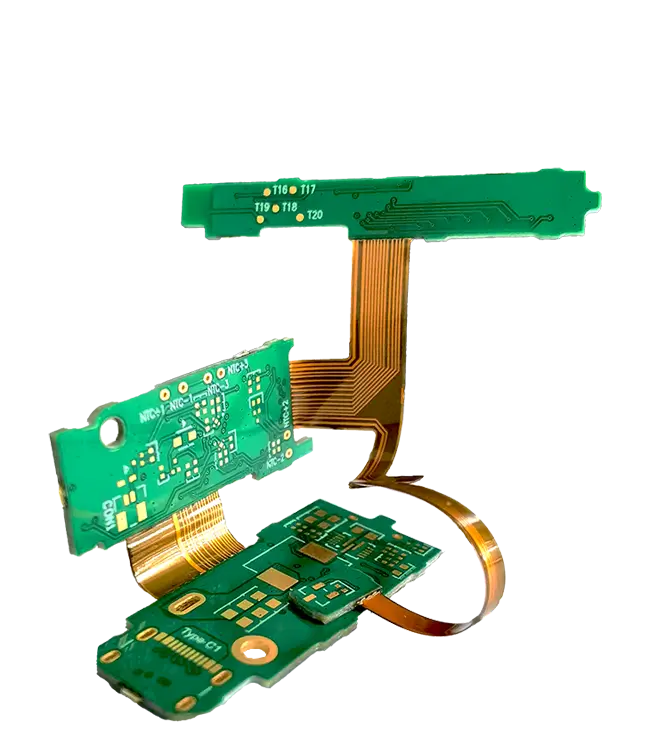

“Rigid-Flex” is a hybrid construction deriving its benefits by joining rigid circuit sections with flex circuits.

This blend of 2-D and 3-D structures can be flexed or bent in all three directions without losing any electrical performance.

As a reliable manufacturer of rigid-flexible PCBs, we offer customized solutions for compact and highly dependable electronic assemblies.

Our flex-rigid PCBs actually improve high-end flex assembly capabilities, delivering exceptional strength and versatility. They are suitable for the most demanding applications, such as aerospace, medical, automotive, and industrial automation.

What Is a Rigid-Flex PCB?

A rigid-flex PCB, sometimes called a flex-rigid PCB or flex-rigid circuit board, is a mixed-type circuit board. It can include flexible circuit substrates as part of its design.

This integration ensures signal integrity on both flex and rigid zones without extra connectors or cables.

Rigid-flex circuits are better than using both rigid and flexible PCBs. They take up less space, provide stronger connections, and fit into smaller areas.

Common Rigid-Flex Circuit Stack-Up Structures

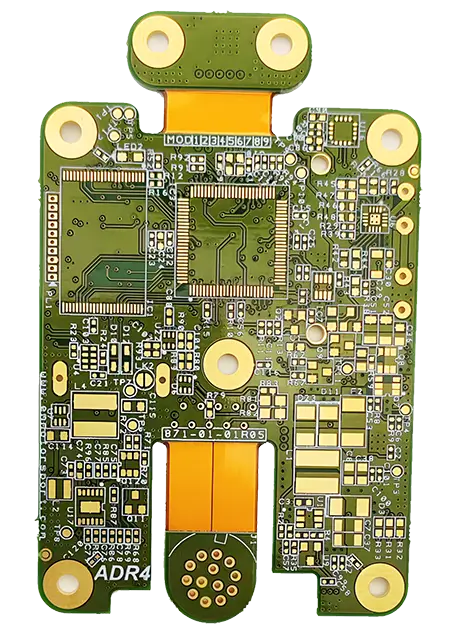

We offer multiple rigid flex PCB stackup configurations to match various electronic design requirements

| Stack-Up Type | Description |

|---|---|

| Single-Layer Flex with Rigid | One flexible layer connects rigid boards. Cost-effective for basic flex needs. |

| Multilayer Flex with Rigid | Multiple flexible layers sandwiched between rigid sections. Supports complex routing. |

| Symmetrical Stack-Up | Balanced layers around a central flexible core for structural symmetry. |

| Asymmetrical Stack-Up | Layer imbalance allows for unique mechanical or component constraints. |

To ensure proper layer transitions and electrical performance, our engineers adhere to IPC-2223 and IPC-6013 standards. We also align with PCB capabilities when advising customers on custom stack-up and layout planning.

10-layer-rigid-flex-pcb-stack-up(The image is from the internet.)

12-layer-rigid-flex-pcb-stack-up-with-air-gap(The image is from the internet.)

Applications of Rigid Flex PCB Technology

In many applications, rigid flex and flex PCBs are used:

Aerospace: Avionics, satellites, missile systems.

Medical: Pacemakers, wearable monitors, diagnostic tools.

Consumer Electronics: Smartphones, cameras, smart wearables.

Automotive: Battery control, ADAS, infotainment systems.

Telecom: Antennas, routers, base stations.

Industrial Equipment: Robotics, automation, process control.

AR/VR Devices: Flexible connectivity and lightweight construction.

For all these, we offer advanced flex PCB assembly, flex PCB connectors, and rigid flex boards to meet your specific needs.

Key Benefits of Flex and Rigid-Flex PCBs

A rigid flex circuit board offers superior performance over a standard printed circuit board

Space Optimization: Eliminate connectors and reduce wire harnesses.

Improved Reliability: Fewer interconnects mean higher mechanical durability.

3D Flexibility: Supports compact designs in wearable and foldable devices.

Superior Signal Integrity: Shorter paths reduce EMI and signal degradation.

Lower Assembly Costs: Consolidated design reduces the number of parts and processing steps.

Whether you need flexible PCB boards, rigid circuit boards, or flex and rigid flex combinations, we deliver reliable circuit solutions customized to your application.

Rigid Flex PCB Fabrication Process

Our rigid flex PCB fabrication process includes:

Material Selection: We choose suitable flex materials like polyimide, LCP, or PET, paired with rigid substrates like FR4.

Layer Stack-Up Design: Ensures consistent impedance, flexibility, and mechanical stability.

Imaging & Etching: High-resolution circuit patterning using photoresist and etchants.

Lamination: Heat and pressure bond flexible and rigid sections into a unified board.

Drilling & Plating: Supports blind and buried vias for complex interconnects.

Solder Mask Application: Protects circuits from oxidation and bridging.

Surface Finishes: ENIG, OSP, and HASL improve solderability and longevity.

Testing & Inspection: Electrical testing, X-ray inspection, and flex endurance evaluation.

We manufacture flexible circuits, rigid PCBs, and hybrid rigid flex circuit boards under strict process control to ensure exceptional quality and performance.

Core Material Comparison for Flex Rigid PCBs

| Material | Thickness Range | Min Bend Radius | Dielectric Constant | Best Use Case |

|---|---|---|---|---|

| Polyimide (PI) | 25–125 μm | ≥ 6 mm | 3.4–3.5 | High-temp & harsh environments |

| LCP | 25–100 μm | ≥ 6 mm | 2.9 | Low-loss, high-frequency RF |

| PET | 50–175 μm | ≥ 8 mm | 3.0 | Cost-effective, flexible PCB boards |

These flex PCB materials offer trade-offs in cost, thermal tolerance, and signal performance. For dynamic applications, flexible printed circuit boards with PI and rolled copper layers provide the best durability.

Rigid-Flex Design Considerations

Designing a rigid flex PCB involves several engineering challenges:

Controlled Bend Radius: Minimize strain to prevent cracks in flex regions.

Layer Transition Zones: Taper copper and use teardrops to avoid stress points.

Component Placement: Avoid placing heavy components on bending sections.

Impedance Control: Maintain uniform dielectric layers throughout the stack-up.

Thermal Management: Ensure even heat dissipation across rigid and flex areas.

Flex Cut Strategy: Understand the difference between flex cut and non-flex cut PCBs to maintain reliability.

DFM Compliance: Collaborate with your rigid flex PCB manufacturer early for manufacturability and cost efficiency.

Cost Optimization for Flex-Rigid PCB Projects

While rigid flex PCBs may appear expensive, the total cost of ownership can be reduced through:

DFM-Oriented Design: Minimizes rework, increases yield.

Shared Panels: Efficient panelization lowers material waste.

Layer Simplification: Fewer layers mean faster builds and lower costs.

Semi-Flex Alternatives: Use flexing boards or flex jumpers when applicable.

Standardized Materials: Selecting ENIG or HASL finishes reduces procurement time.

We support fast-turn rigid flex PCB fabrication for prototyping and medium-volume production.

Industry Standards and Reliability Testing

Our rigid flex PCB manufacturing process adheres to international performance and reliability benchmarks:

Thermal Cycling: Assesses resistance to heat fluctuations.

Flex Life Testing: Validates dynamic flex durability.

Moisture Resistance: Tests dielectric stability under humidity.

Microsection Analysis: Evaluates via integrity and lamination quality.

Electrical High-Pot: Confirms insulation and breakdown voltage.

Compliant with IPC-6013C, UL 796F, and MIL-PRF-31032, our boards meet quality expectations across defense, medical, and industrial sectors.

Technical Capabilities Overview

| Capability | Flex | Rigid-Flex | Rigid |

|---|---|---|---|

| Min Layers | 1 | 2 | 1 |

| Max Layers | 8 | 12 | 32+ |

| Max Copper (Outer) | 2 oz | 2 oz | 6 oz |

| Max Panel Size | 600×600 mm | 600×600 mm | 1200×1200 mm |

| Min Drill (Laser) | 0.05 mm | 0.05 mm | 0.10 mm |

| Blind/Buried Vias | No | Yes | Yes |

| Conductive Fill | No | Silver | Copper |

| Impedance Control | ±10% | ±7% | ±5% |

| Sequential Lamination | No | ≤3 | ≤6 |

For more details, explore our flex PCB board, rigid PCB, and flexible circuit connector options. We are a proven flex PCB manufacturer with rapid turnaround and global delivery.

Get A Quote